Automatic part picking machine

A technology of automatic pick-up and pick-up machine, which is applied in the field of mechanical automation, can solve the problems of unsuitability for large-scale use, slow speed, high cost, etc., and achieve the effect of stable and fast calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

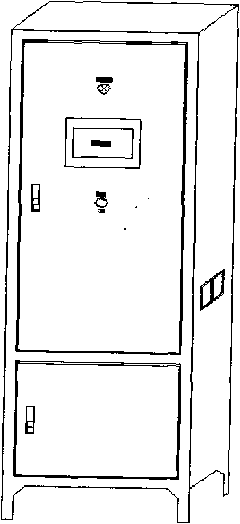

[0020] Embodiment 1: as figure 1 and figure 2 As shown, an automatic pick-up machine includes a pick-up control system device, a pick-up machine base 1, a height-adjustable threaded guide post 2 is provided on the pick-up machine base 1, and a threaded guide post 2 is arranged on the threaded guide post 2 There is a tray bottom plate 3, and the tray bottom plate 3 is provided with a tray device and a picker box body frame 9, and the picker machine also includes a picker box body 5, and the picker box body 5 passes through the picker box body frame 9 and the tray bottom plate. 3 are connected, and a pick-up advance arm 7 is arranged in the pick-up machine box body 5. The tray device includes a tray arm 11 that can rotate 90 degrees in parallel. One end is provided with a connecting product tray 10, under the connecting product tray 10 is provided with a tray turning cylinder 13 that can make the connecting product tray 10 turn over and a stepper motor 4 that controls the move...

Embodiment 2

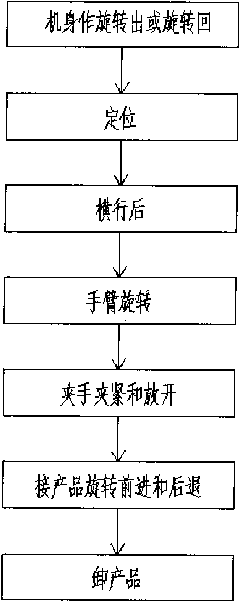

[0021] Embodiment 2: Under the automatic state of the automatic pick-up machine of the present invention: as Figure 4 Shown: Select the button as the automatic position, press start to start, the pick-up machine turns from the initial position to the mold position that is installed on the die-casting machine, and when the die-casting machine is in place for a cycle of production, the arm of the pick-up machine moves forward → stretches into the mold Clamp the ejected product in the interior → after horizontal movement → arm back → arm back to the middle position → spray, spray the release agent on the mold, and prepare for the next cycle of die casting → arm rotation → arm back limit → loosen the clamp, put The product is placed on the rotating disk for receiving the product, and it starts to calculate whether the product has reached the preset weight. If there is an error or an error occurs, it will stop and alarm→connect the product and rotate back→unload the product→connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com