Full-automatic vacuum test tube uncapping machine

A test tube capping machine, fully automatic technology, applied in the direction of stopper removal, etc., can solve the problems of high cost, affecting test results, low efficiency, etc., and achieve the effect of simple and low manufacturing cost, simple capping process, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

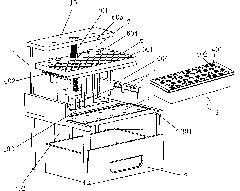

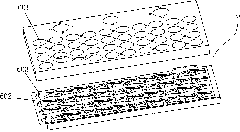

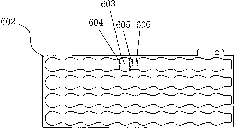

[0030] A fully automatic vacuum test tube decapping machine, such as Figure 1-6 As shown, it includes a frame 1, a test tube cap collection box 2, a cap removal frame 6, a cap removal frame lifting drive device and a test tube box 4, and the test tube cap collection box 2 is arranged at the bottom of the frame 1, and a test tube box is arranged in the middle of the frame 1 The positioning device and the test tube box transfer device, the test tube box positioning device is arranged on the rear side of the middle part of the frame 1, the test tube box transfer device is arranged on the front side of the frame 1 middle part, and the cap removal frame 6 is arranged above the test tube box positioning device, and the cap removal frame lifts The driving device is installed on the rear side of the frame 1, and the test tube box 4 is placed on the test tube box transfer device. Extrusion hole 402, a rubber sleeve or rubber ring 403 is provided in the cylindrical hole 401, the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com