Method for measuring and controlling tower column and cable pipeline in synchronous construction of tower and beam of cable-stayed bridge

A technology of measurement control and simultaneous construction, applied to cable-stayed bridges, bridges, bridge forms, etc., can solve problems such as reduced construction efficiency, easy fatigue of personnel, unknown deformation, etc., achieve positive economic and social benefits, and reduce construction safety risks , The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with examples.

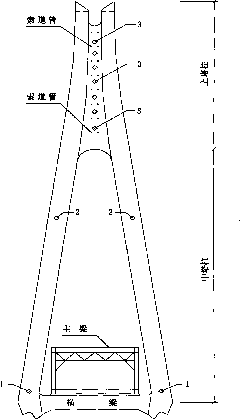

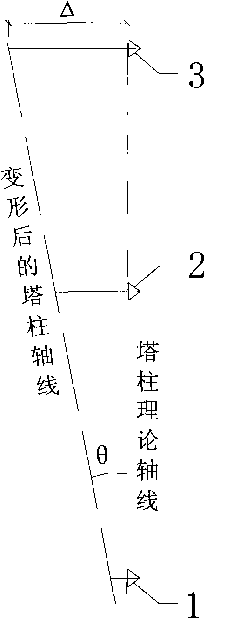

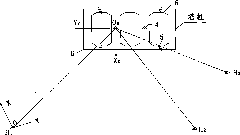

[0033] Such as figure 1 After the construction of the cross beam of the tower column is completed, start the construction of the tower column and the upper tower column in sections. At the same time, the main beam construction can be started synchronously according to the construction needs, that is: the simultaneous construction of the tower beam. During the construction of the tower column, bury the prism head at the root of the middle tower column, set the E group measuring point 1, set the prism head on the upper part of the tower column, set the F group measurement point 2, and set the prism head on the upper tower column, set the G group Measuring point 3.

[0034] Group E measuring points 1, F group measuring points 2, and G group measuring points 3 are one or two respectively, which are all arranged on the outer surface of the tower column facing the main beam. The number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com