Anti-vibration actuator and lens unit/camera equipped therewith

A lens unit and actuator technology, which is applied in the field of camera devices and lens units, can solve the problems of not being able to directly control the rotation and movement of the lens used for image stabilization, and the reduction of image stabilization accuracy, and achieve large driving force, suppression of rotation and movement, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

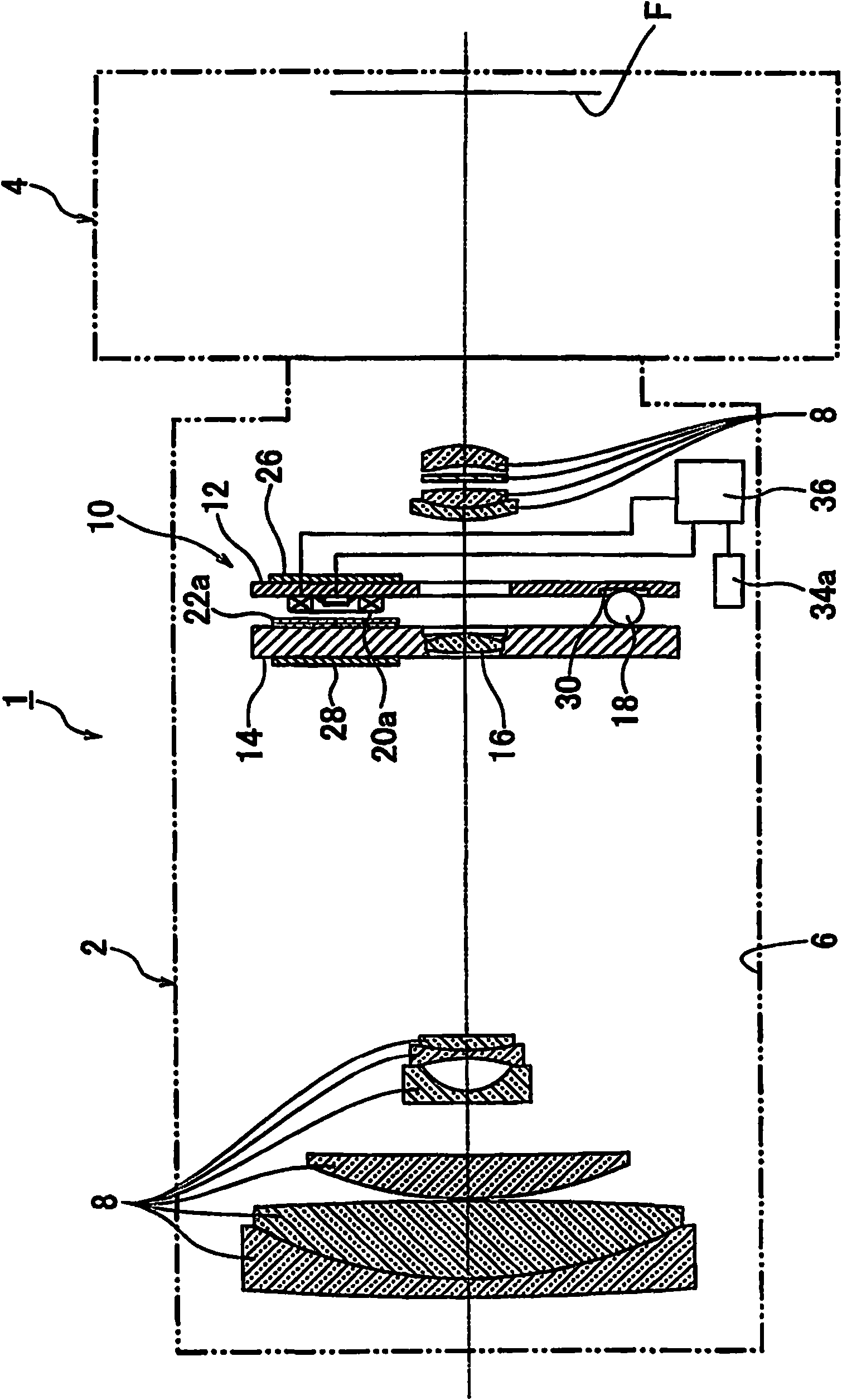

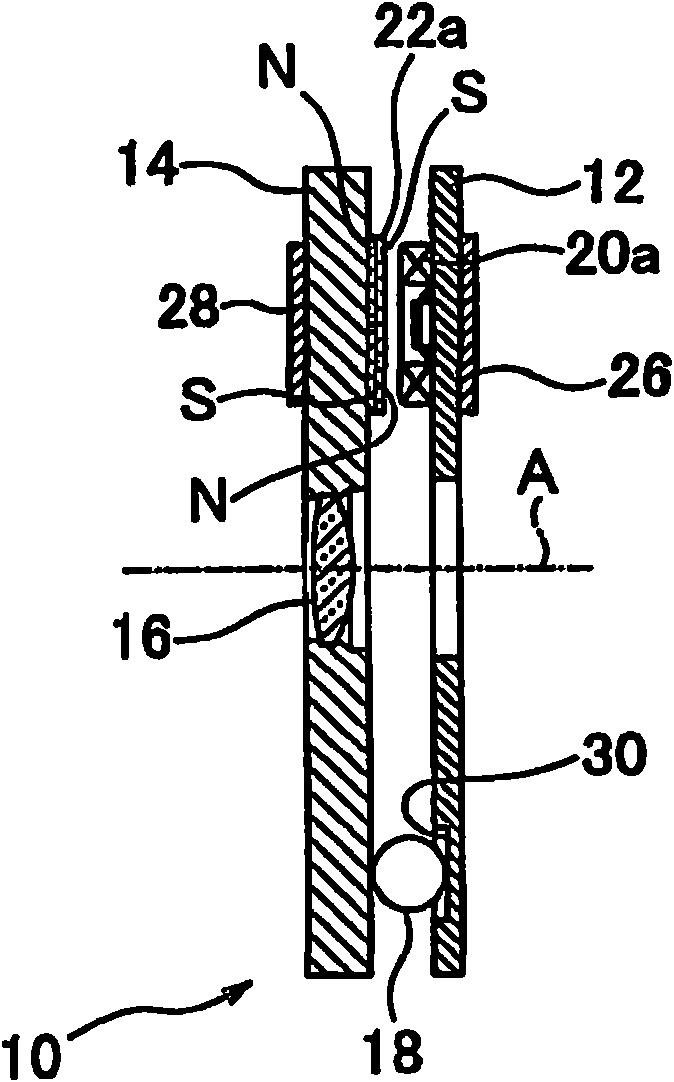

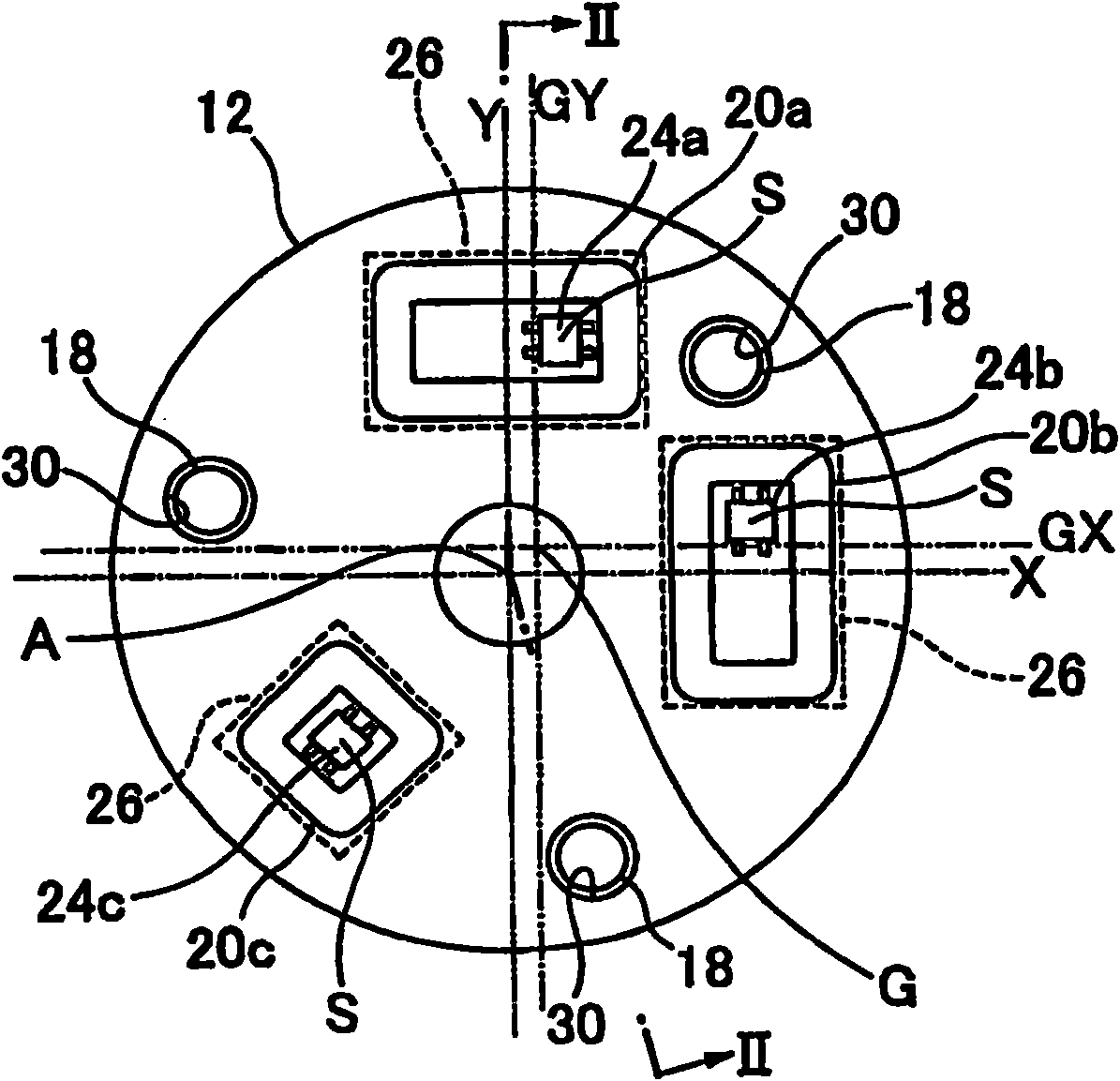

[0043] First, refer to Figure 1 to Figure 8 An imaging device according to an embodiment of the present invention will be described. figure 1 It is a cross-sectional view of the imaging device according to the embodiment of the present invention.

[0044] Such as figure 1 As shown, an imaging device 1 according to an embodiment of the present invention includes a lens unit 2 and an imaging device main body 4 . The lens unit 2 includes a lens barrel 6, a plurality of photographing lenses 8 arranged in the lens barrel, an anti-vibration actuator 10 for moving an image stabilizing lens 16 in a predetermined plane, and a sensor for detecting the lens barrel. The vibration detection parts of 6 vibrations are gyroscopes 34a, 34b ( figure 1 Only 34a) is indicated in .

[0045] The imaging device 1 according to the embodiment of the present invention detects vibrations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com