Screw compressor

A screw compressor, screw technology, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve the problems of compression torque pulsation of twin or single screw compressor, reduction of single noise of axial fan, etc. Achieve the effect of avoiding switching, reducing compression torque fluctuation, and easy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0098] (Features of the first embodiment)

[0099] (1)

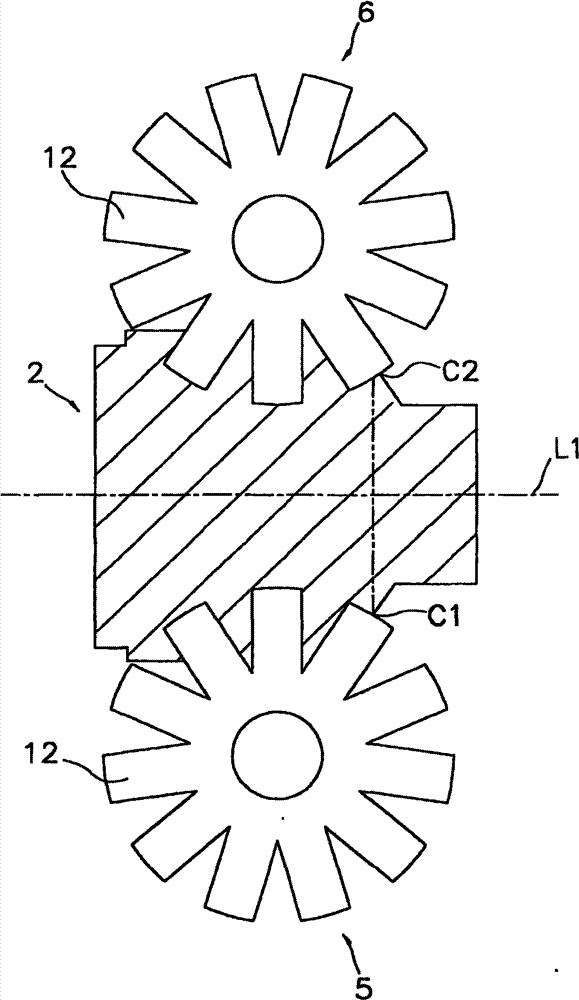

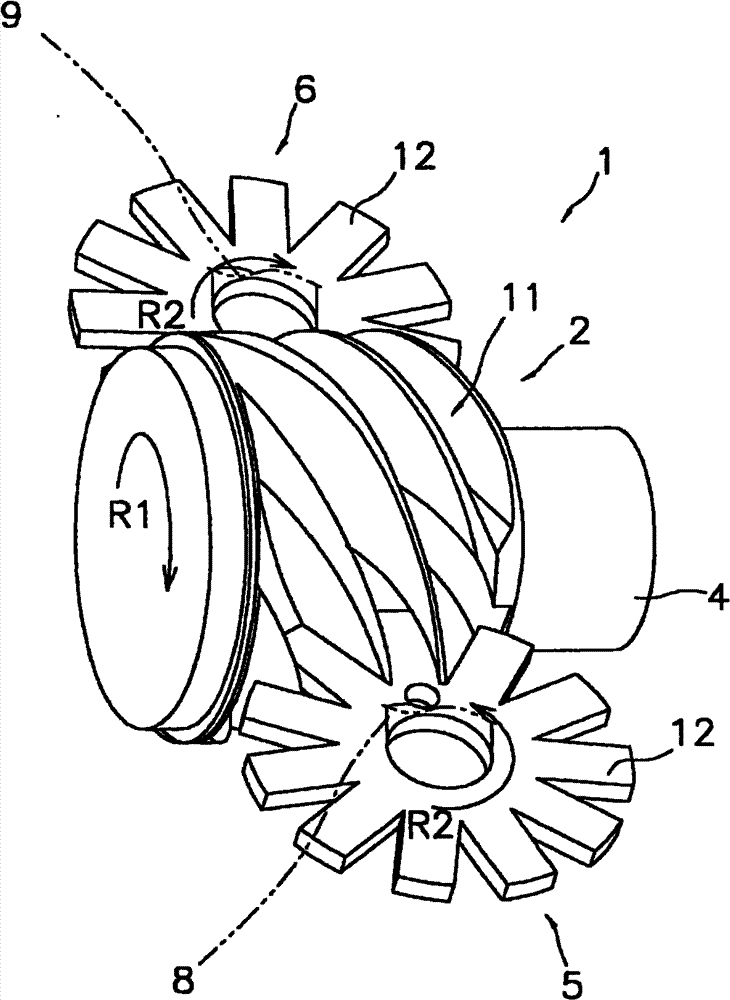

[0100] In the single screw compressor 1 of the first embodiment, at least one tooth 12 (eg, Figure 4 The teeth 12 a 1 , 12 a 2 , 12 b 1 , and 12 b 2 of (a) are arranged unevenly with respect to the other teeth 12 in the circumferential direction of the rotation shafts 8 , 9 . In addition, the plurality of helical grooves 11 of the screw rotor 2 are arranged in the circumferential direction of the rotary shaft 4 so as to be able to mesh with the plurality of teeth 12 .

[0101] Accordingly, it is possible to significantly reduce the compression torque variation and the resulting torque ripple that occur in the conventional screw in which grooves and teeth are arranged at equal intervals. As a result, it is possible to reduce noise and vibration accompanying compression torque fluctuations. Furthermore, it is possible to reduce noise and vibration accompanying suction and discharge flow rate fluctuations and pressure p...

no. 2 approach

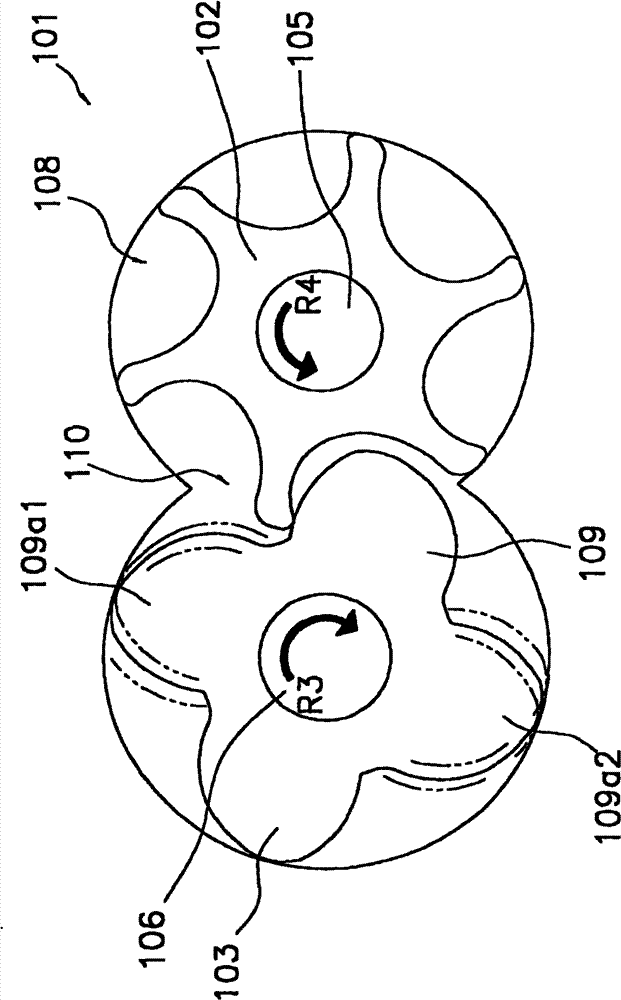

[0136] Next, the twin-screw compressor 101 which is one embodiment of the screw compressor of the present invention will be described with reference to the drawings.

[0137] (Structure of twin-screw compressor 101)

[0138] Figure 7-8 The illustrated twin-screw compressor 101 includes: a female rotor 102, a male rotor 103, a housing 104 for accommodating the female rotor 102 and the male rotor 103, a first rotating shaft 105 serving as the rotating shaft of the female rotor 102, and a male rotor 103. The second rotating shaft 106 of the rotating shaft, and the rolling bearings 107a, 107b, 107c, and 107d that rotatably support the first rotating shaft 105 and the second rotating shaft 106 inside the housing 104 .

[0139] Figure 7-8 The illustrated female rotor 102 and male rotor 103 are arranged horizontally, but they may also be arranged vertically.

[0140] Here, the female rotor 102 corresponds to the first engaging body of the present invention. In addition, the mal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com