Thin film type solar cell and method for manufacturing the same

一种太阳能电池、薄膜型的技术,应用在太阳能电池领域,能够解决薄膜型太阳能电池过程复杂等问题,达到精确划分、防止问题、防止电阻增大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

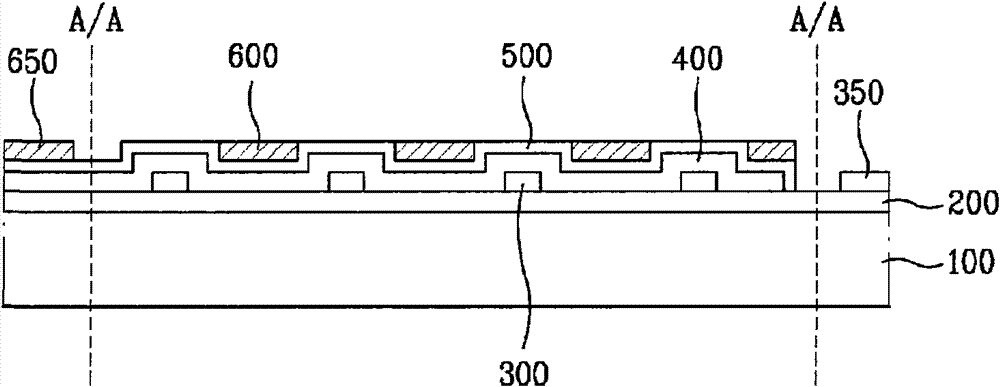

[0077] figure 2 is a sectional view illustrating the thin film type solar cell according to the first embodiment of the present invention.

[0078] Such as figure 2 As shown, the thin film solar cell according to the first embodiment of the present invention includes: a substrate 100 , a front electrode layer 200 , an auxiliary electrode 300 , a semiconductor layer 400 , a transparent conductive layer 500 and a back electrode 600 .

[0079] Here, the substrate 100 may be formed of glass or transparent plastic. The transparent conductive layer 200 is formed on the substrate 100, wherein the transparent conductive layer 200 can be made of such as ZnO, ZnO:B, ZnO:Al, ZnO by sputtering or MOCVD (Metal Organic Chemical Vapor Deposition, Metal Organic Chemical Vapor Deposition) method. :H, SnO 2 , SnO 2 : F or ITO (indium tin oxide) and other transparent conductive materials.

[0080] In addition, the front electrode layer 200 corresponds to the incident surface of the sun's ...

no. 2 example

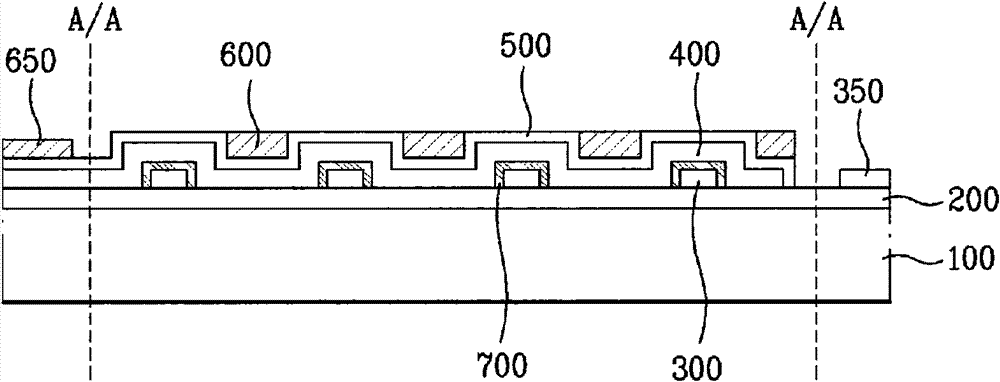

[0105] image 3 is a sectional view illustrating a thin film type solar cell according to a second embodiment of the present invention.

[0106] Except that the insulating layer 700 is additionally provided, the thin-film solar cell according to the second embodiment of the present invention is structurally the same as the thin-film solar cell according to the first embodiment of the present invention, therefore, the The same reference numerals are used throughout the drawings to denote the same or similar parts, and detailed descriptions of the same parts are omitted.

[0107] The thin film type solar cell according to the second embodiment of the present invention additionally includes an insulating layer 700 covering the auxiliary electrode 300 , that is, the insulating layer 700 is formed on side and upper surfaces of the auxiliary electrode 300 . More specifically, the insulating layer 700 is formed on Figure 8 On the side surfaces and upper surfaces of the first auxil...

no. 3 example

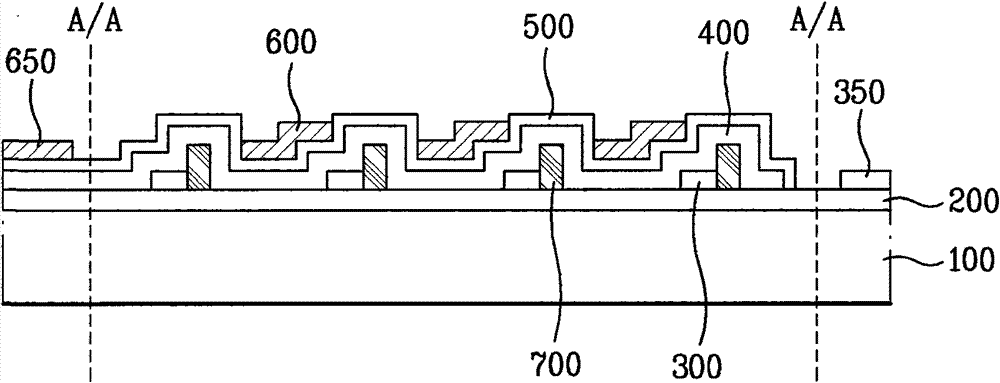

[0112] Figure 4 is a cross-sectional view illustrating a thin film type solar cell according to a third embodiment of the present invention.

[0113] Except that an insulating layer 700 is additionally provided, the thin-film solar cell according to the third embodiment of the present invention is structurally the same as the thin-film solar cell according to the first embodiment of the present invention, therefore, all The same reference numerals are used in the drawings to denote the same or similar parts, and detailed descriptions of the same parts are omitted.

[0114] The thin film type solar cell according to the third embodiment of the present invention additionally includes an insulating layer 700 , wherein the insulating layer 700 is formed on one side of the auxiliary electrode 300 . More specifically, the insulating layer 700 is formed on Figure 8 One side of the first auxiliary electrode 310 shown in A to 8D, wherein the insulating layer 700 is higher than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com