Commutation device and electric machine

A commutation device and commutator technology, applied in the direction of circuits, current collectors, electrical components, etc., can solve problems such as short circuit, shortened service life of motors, deposition, etc., and achieve the effects of increasing service life, avoiding deposition, and avoiding electrical short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

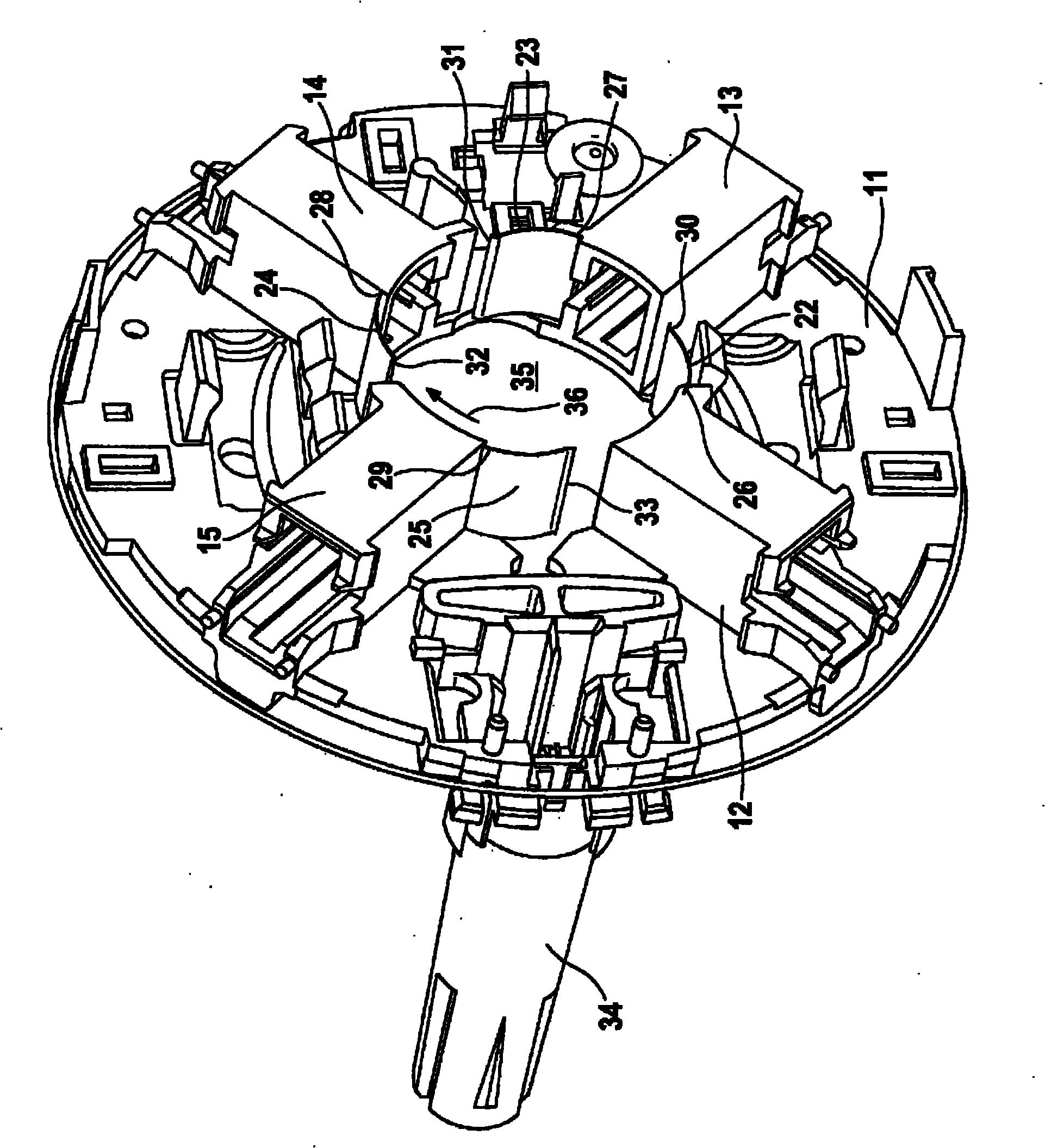

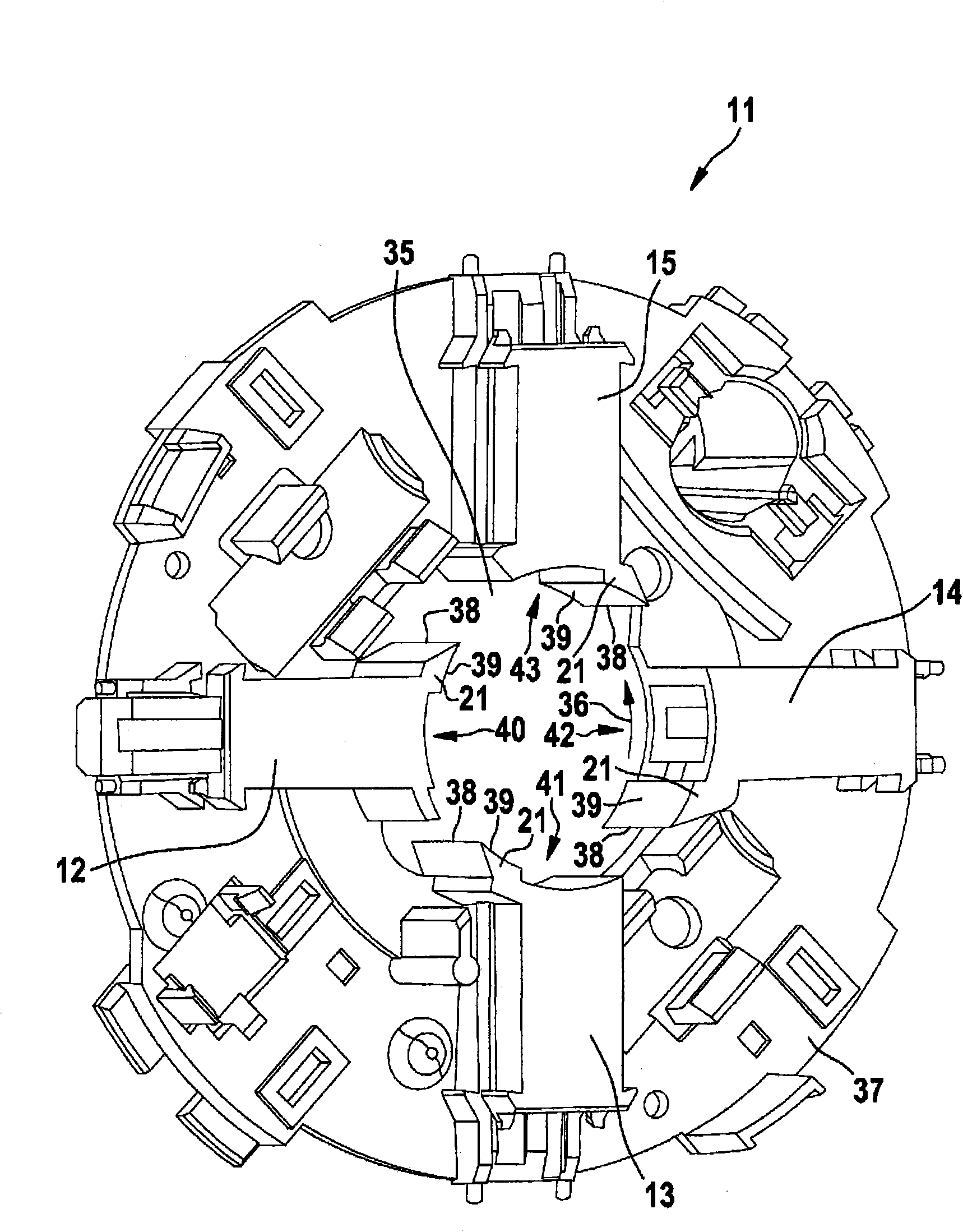

[0025] In the figures, the same components and components with the same function are marked with the same reference numerals.

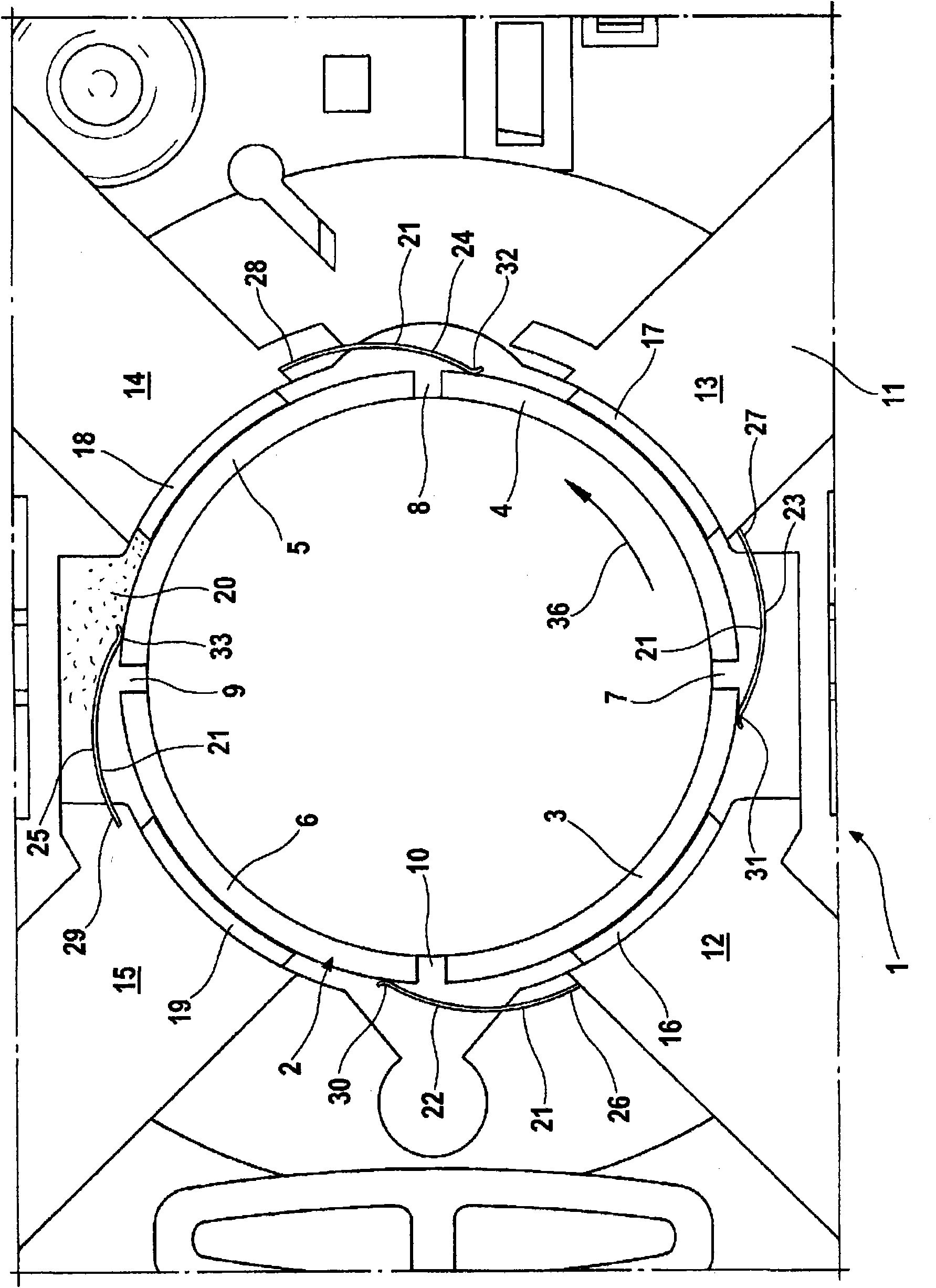

[0026] exist figure 1 A commutation device 1 for an electric motor is shown in . The commutation device 1 comprises a commutator 2 which is arranged in a non-rotatable manner on a not shown armature shaft standing perpendicularly on the plane of the drawing. In the exemplary embodiment shown, the commutator 2 comprises four copper laminations 3 , 4 , 5 , 6 arranged next to each other in the circumferential direction. The laminations 3 , 4 , 5 , 6 are electrically conductively connected to an armature winding (not shown) of the armature lamination stack. An air gap 7 , 8 , 9 , 10 extending in the axial direction is provided between every two adjacent lamellae in order to keep the lamellae 3 , 4 , 5 , 6 electrically insulated from one another.

[0027] The commutator 2 is arranged inside a brush element carrier 11 which in this embodiment has four slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com