Automatically-rotating flusher for wet desulfurization demister

An automatic rotation and wet desulfurization technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of wasting maintenance time, affecting the power generation process, and pipe network breakage, etc., and achieves convenient use of units and extended use Life expectancy and the effect of reducing the number of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

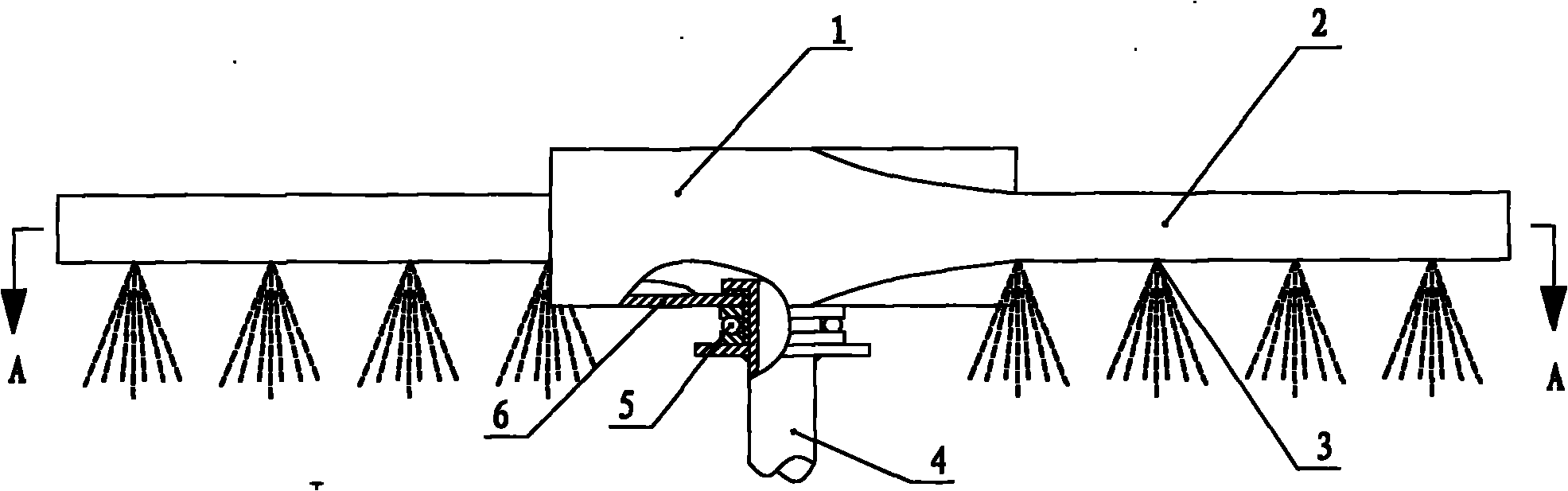

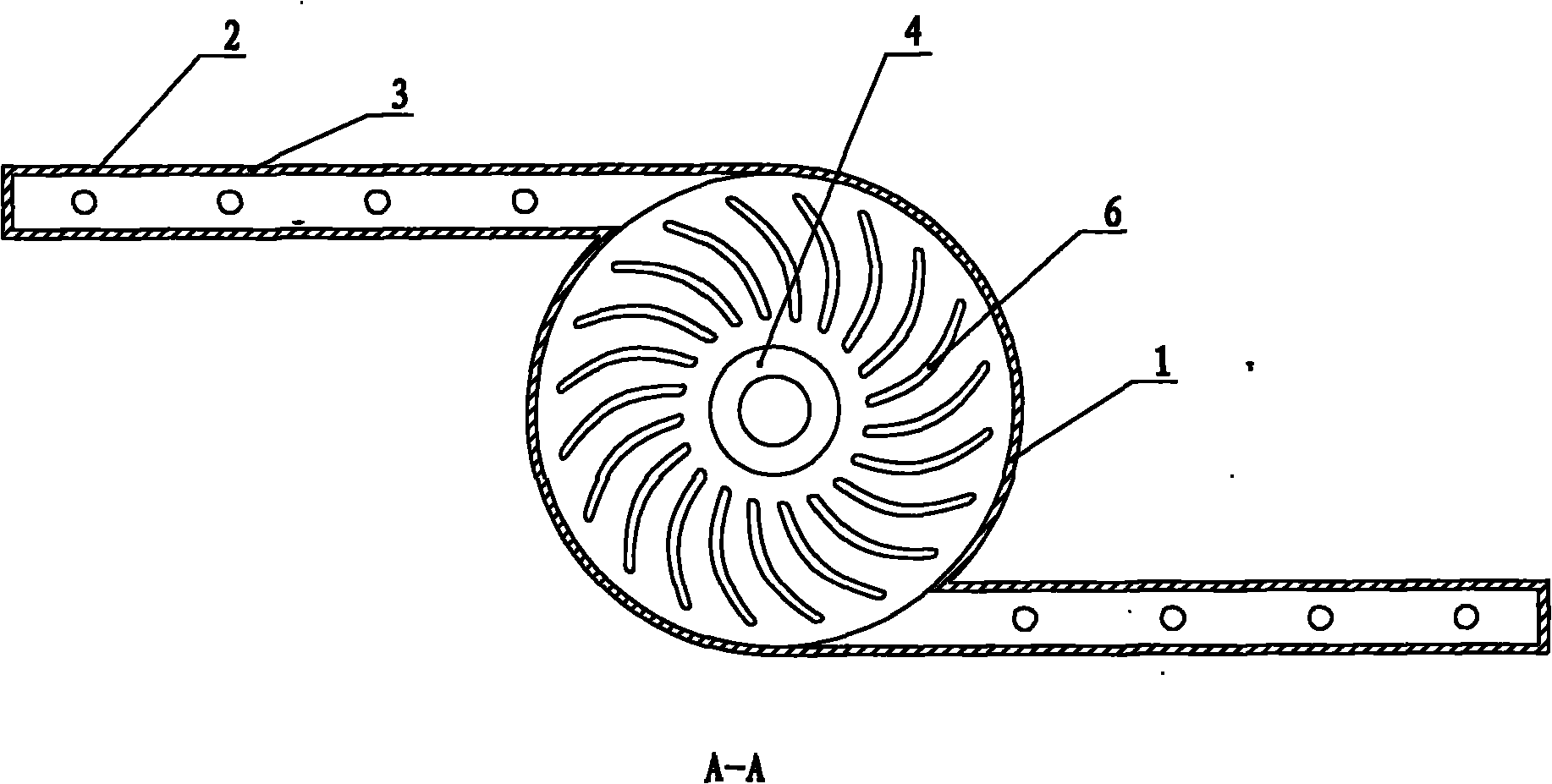

[0024] Embodiment one: see figure 1 , figure 2 , an automatic rotary flushing device for a wet desulfurization demister in the figure, which contains a vertical shaft tube and a rotary sprinkler. The rotary sprinkler contains a circular drive box in the middle and symmetrically connected to the drive box. There are two surrounding spray pipes, spray holes or spray devices are evenly distributed under the spray pipes, the free ends of the spray pipes are closed, and the vertical shaft pipe is installed in the middle of the lower wall of the drive box through bearings , the upper wall or the inner surface of the lower wall of the drive box is provided with a certain number of raised rotating ribs, the rotating ribs are left-handed or right-handed; the spray pipe is driven along the circular drive box The cylindrical surface of the cylinder is arranged tangentially, and its rotation direction matches the rotation direction of the rotating convex line in the box body. There are...

Embodiment 2

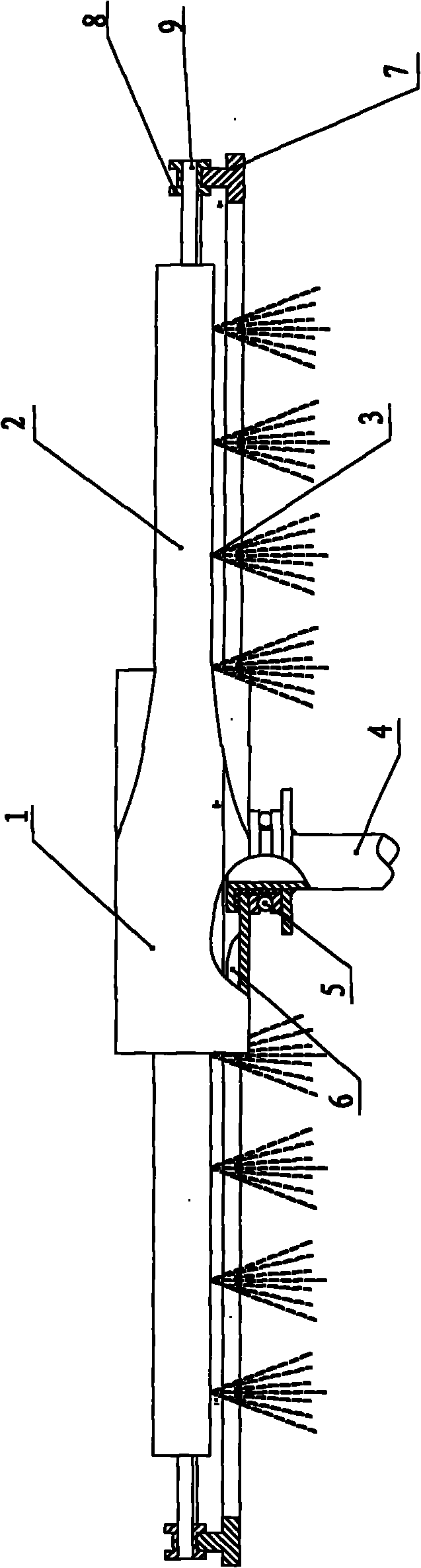

[0027] Embodiment two: see image 3 , an automatic rotary flushing device for a wet desulfurization demister, containing a vertical shaft tube and a rotary sprinkler, the rotary sprinkler contains a circular drive box in the middle and symmetrically connected around the drive box There are two spray pipes, spray holes or spray devices are evenly distributed under the spray pipes, the free ends of the spray pipes are closed, and the vertical shaft pipe is installed in the middle of the lower wall of the drive box through bearings, so The upper wall or the inner surface of the lower wall of the drive box body is provided with a certain number of raised rotating ribs, and the rotating ribs are left-handed or right-handed; The surface is arranged tangentially, and its direction of rotation matches the direction of rotation of the ridges in the box. There are two spray pipes. The rotating convex line is a curved convex line.

[0028] Shafts are fixedly installed at both ends of ...

Embodiment 3

[0031] Embodiment three: see Figure 4 , Figure 5 , an automatic rotary flushing device for a wet desulfurization demister in the figure, which contains a vertical shaft tube and a rotary sprinkler. The rotary sprinkler contains a circular drive box in the middle and symmetrically connected to the drive box. There are at least two spray pipes around the spray pipe, spray holes or spray devices are evenly distributed under the spray pipe, the free end of the spray pipe is closed, and the vertical shaft pipe is installed on the lower wall of the drive box through a bearing In the middle part, the upper wall or the inner surface of the lower wall of the drive box body is provided with a certain number of raised rotating ridges, which are left-handed or right-handed; the spray pipe is arranged along the circular drive box The cylindrical surface of the body is arranged tangentially, and its rotation direction matches the rotation direction of the rotating convex line in the box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com