Composite board with new structure

A new type of structure, composite board technology, applied in layered products, chemical instruments and methods, wood layered products, etc., can solve problems affecting the service life of composite boards, affecting life, surface cracks, etc., and achieve economic benefits and social benefits. Significant benefit, increased bonding surface, and stable structure

Inactive Publication Date: 2010-08-18

吴永志

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the solid wood composite panels manufactured by the above-mentioned manufacturing process, there are different degrees of shrinkage and surface cracking under different use environments, which seriously affects the service life of the composite panels.

This is because the base plate is deformed after being heated or damp, and the panel is also deformed, which directly affects its life.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0007] The present invention will be further described in detail in conjunction with the accompanying drawings.

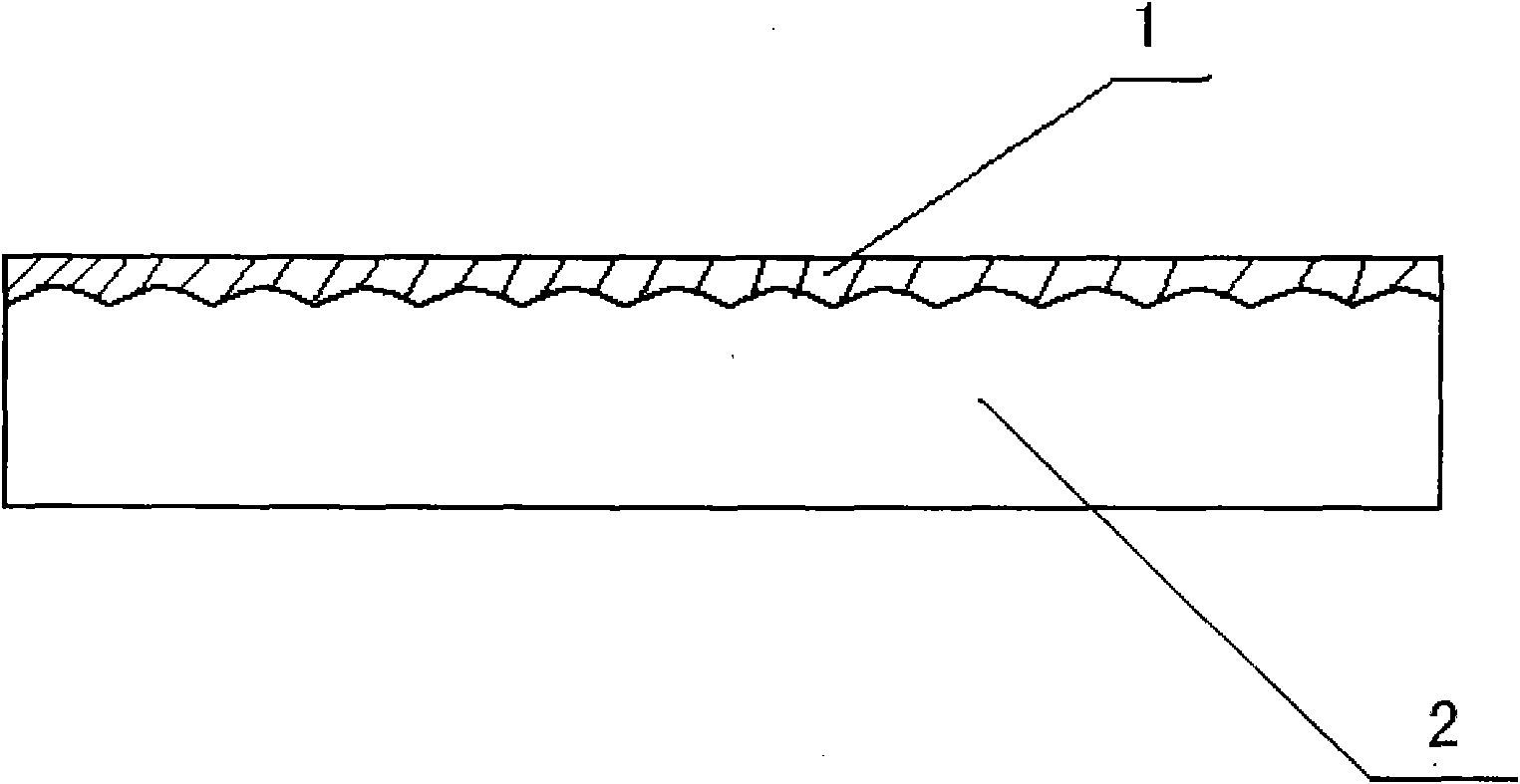

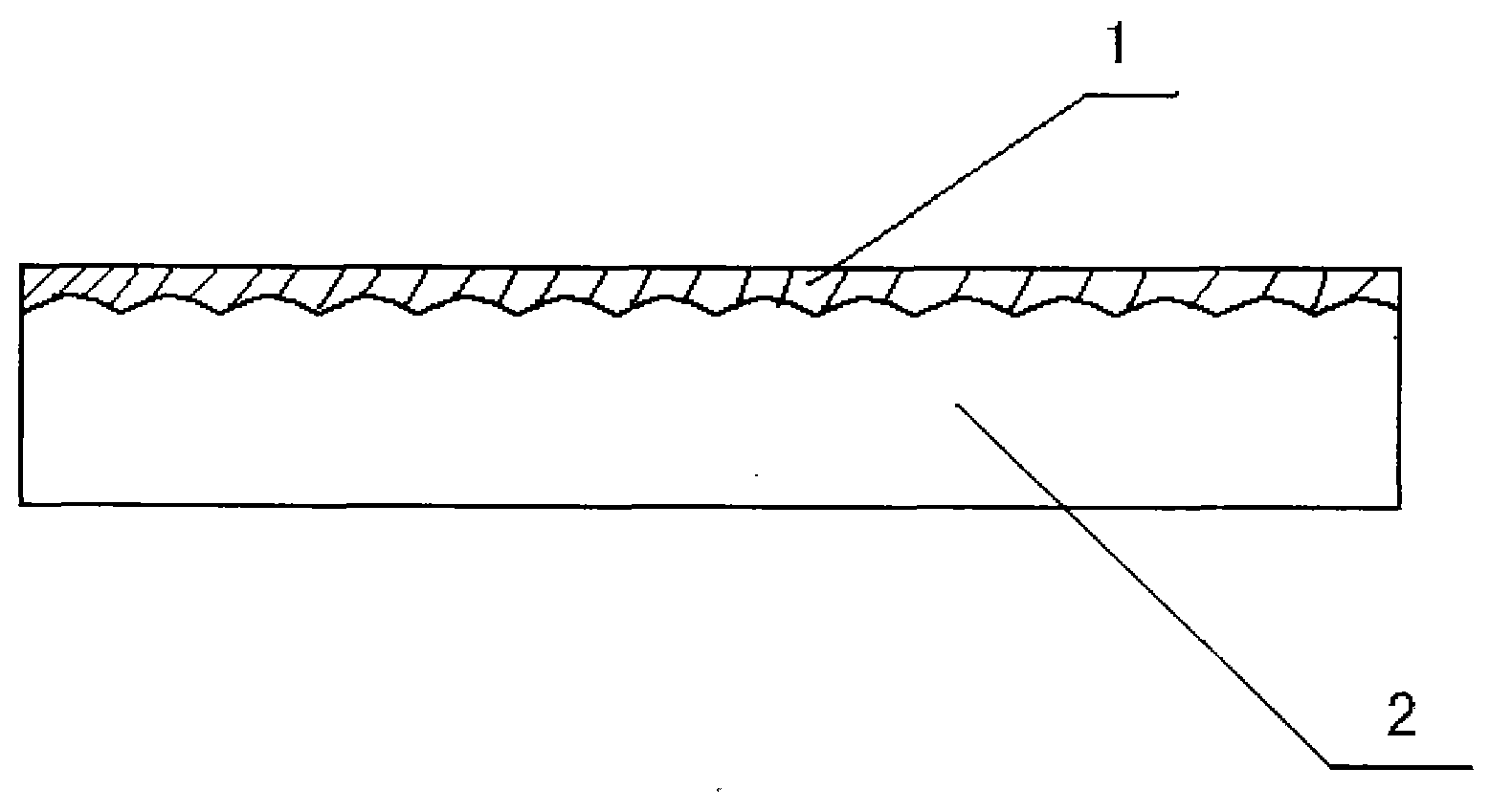

[0008] From figure 1 It can be seen that a composite board includes a solid wood panel 1 and a high-density substrate board 2, the connection surface of the solid wood panel 1 and the high-density substrate board 2 is wave-bonded, and the thickness of the solid wood panel 1 is 0.2-0.4cm. The thickness of the high-density substrate board 2 is 1.0-1.2 cm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to view more

Abstract

The invention discloses a composite board with a new structure. The composite board comprises a solid wood panel and a high density base material board, wherein the connection surface of the solid wood panel and the high density base material board is corrugated; the thickness of the solid wood panel is 0.2-0.4cm, and the thickness of the high density base material board is 1.0-1.2cm. As the structure of panel fiber is stable under the conditions of high temperature and low humidity, the surface of the composite board can not crack; and the automatic production of the composite board can be realized, the cost can be reduced by nearly 30%, and the composite board is characterized by remarkable economic and social benefits and the like.

Description

technical field [0001] The invention relates to a composite board with a new structure, especially a composite board which adopts the combination of solid wood and high-density substrate board. Background technique [0002] The application of composite boards is very common. Its structure has at least one base board. The top of the base board is cold-pressed or hot-pressed with glue and laminated with a layer of wood veneer; its manufacturing process mainly includes 1. Glue between substrates; 2. Hot pressing; 3. Processing. The process is mature, the cost is low, and the glued quality is stable, which meets industrial production. However, due to the fact that the solid wood composite board manufactured by the above-mentioned manufacturing process has shrinkage and surface cracks in different degrees under different use environments, the service life of the composite board has been seriously affected. This is because the base plate is deformed after being heated or damp, a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): B32B21/14B32B7/04

Inventor 吴永志

Owner 吴永志

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap