Application of double-layer aseptic vacuum technique in external package of large volume injection

A vacuum technology and large-capacity technology, which is applied in the field of medical large-capacity injection manufacturing, can solve problems such as patient death, and achieve the effect of reducing medical accidents and ensuring physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

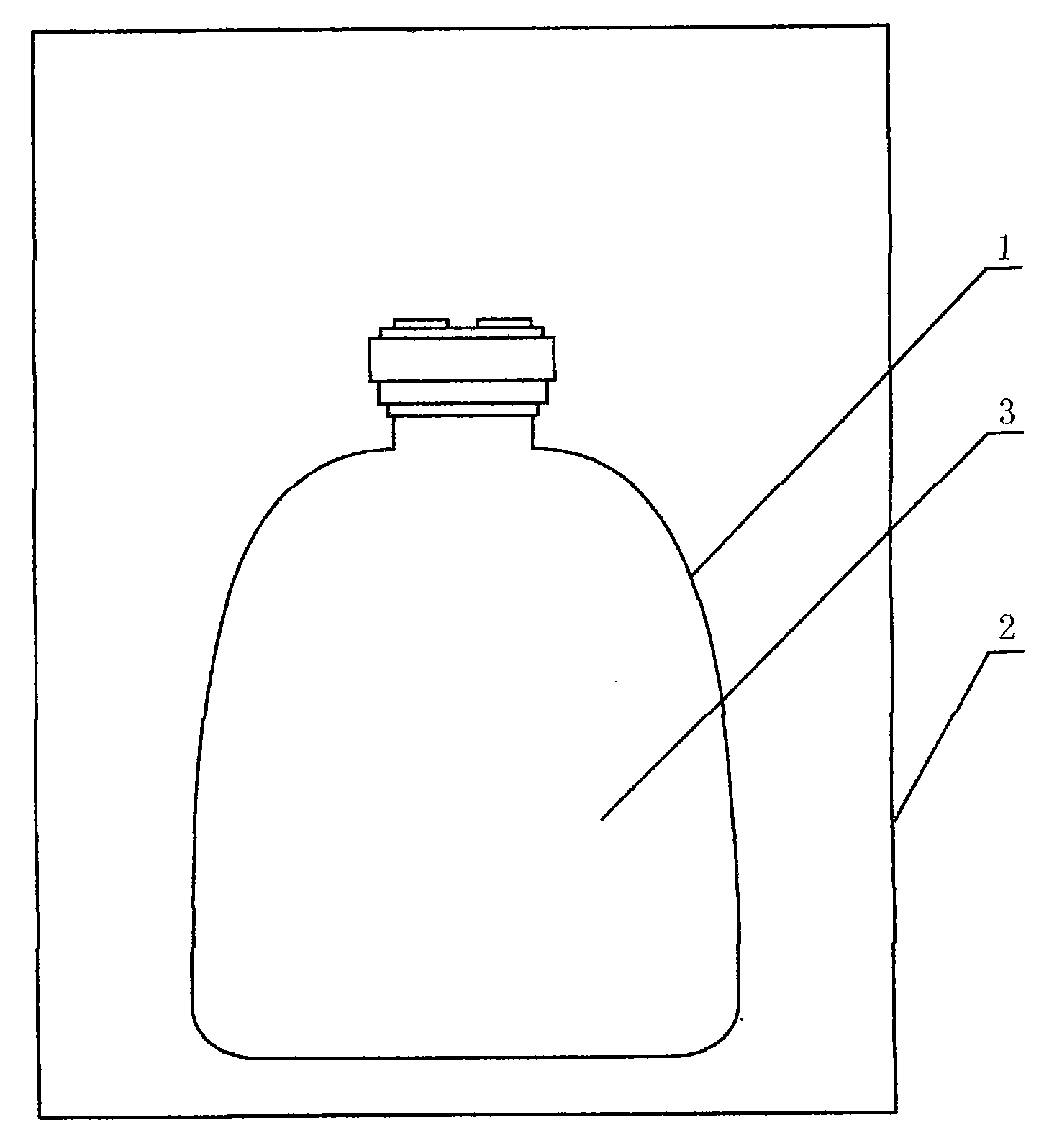

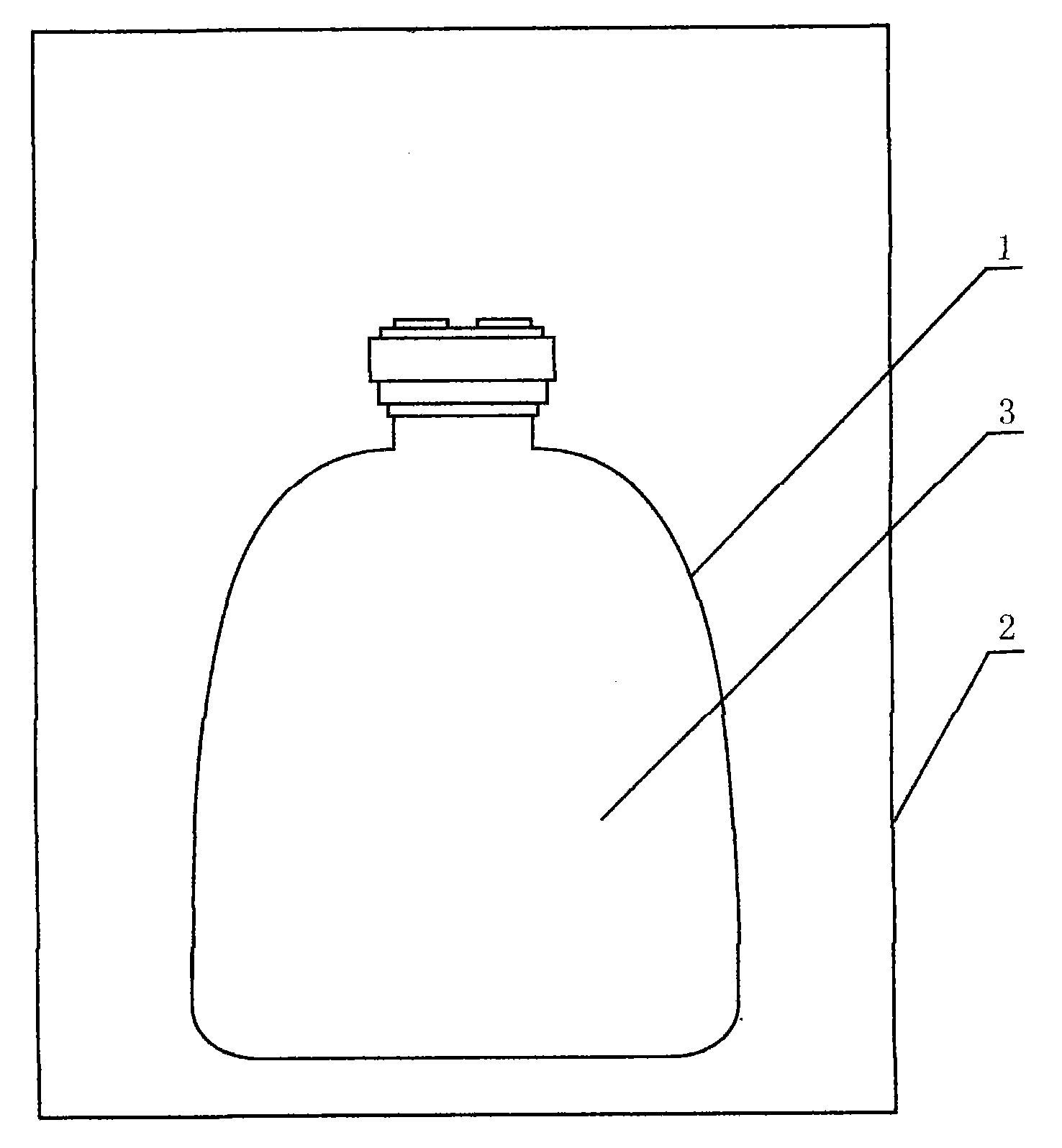

Image

Examples

Embodiment Construction

[0024] Take the non-PVC soft bag infusion bag as an example, and carry out the packaging of large-volume injections according to the following process:

[0025] Step 1: Cut the inner packaging bag in the aseptic workshop, and fill the liquid medicine in the inner packaging to form a large-volume injection.

[0026] Step 2: Pack the filled large-volume injections into protective outer packaging. This process is also carried out in the aseptic workshop.

[0027] The third step: the vacuum is drawn between the protective outer bag and the inner packaging to form a negative pressure, and the protective outer packaging is completely sealed. This process is also carried out in the aseptic workshop.

[0028] Step 4: Put the large-volume injection into the sterilization device for sterilization, the sterilization temperature is 121 degrees Celsius, and the duration: 20-30 minutes.

[0029] Step 5: Dry the sterilized large-volume injection, and then proceed to the subsequent process.

[0030] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com