Rotary blanking device

A blanking device and rotary technology, applied in planting methods, planter parts, transportation and packaging, etc., can solve problems such as low efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

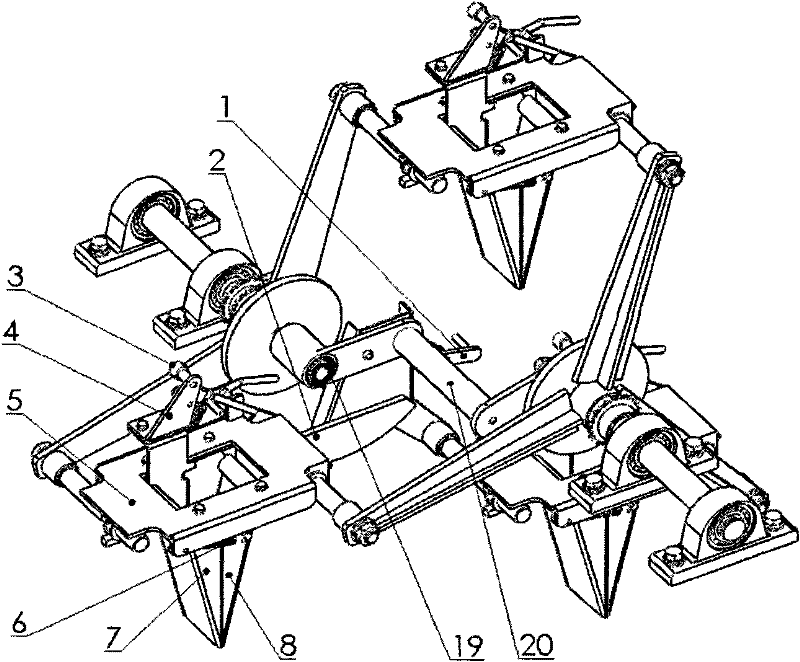

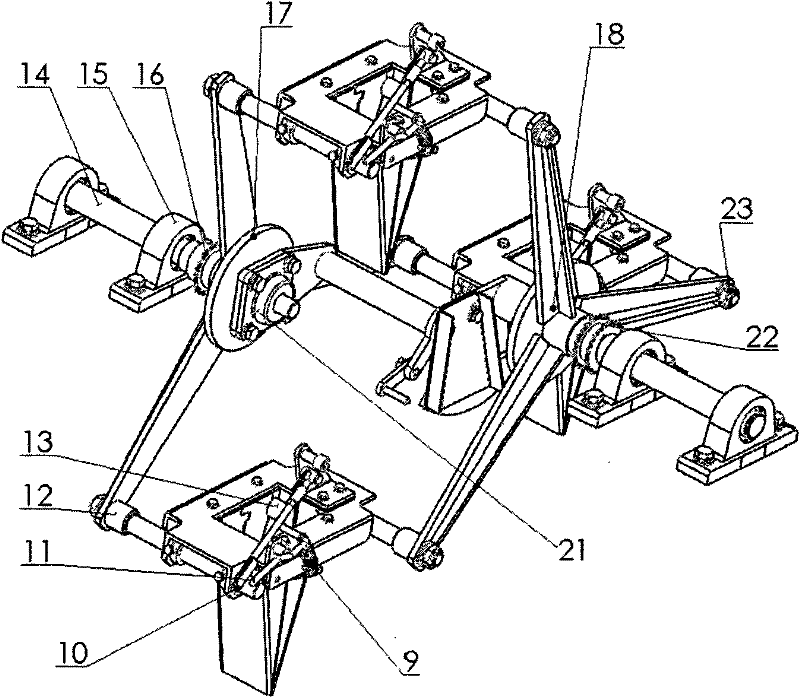

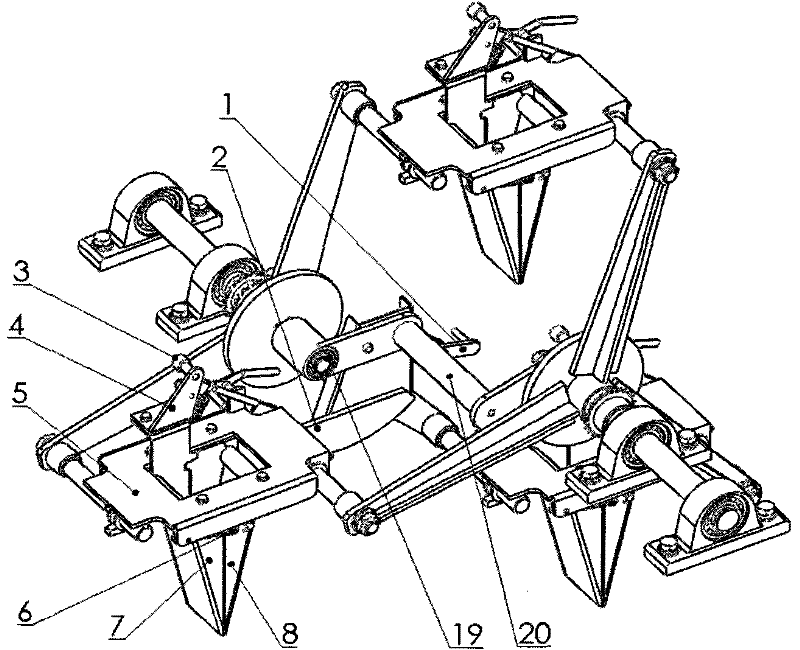

[0009] As shown in the figure, the blanking device of the present invention is composed of two parts: a hopper assembly and a rotary assembly. trigger 11, support rod 12, hopper shaft 13, etc.; the mounting plate 5 is installed on the left and right support rods 12 through shaft holes, and the support rod 12 can rotate in the shaft hole of the mounting plate 5; the hopper shaft 13 is respectively installed on the installation The left and right sides of the plate 5; the push plate 4 is connected to the top of the hopper side plate 7 through bolts; The tension of the spring 6 keeps the hopper closed; the upper parts of the side plates 7 and 8 of the hopper are connected through tooth engagement, and transmit the force required for opening and closing to each other; the nylon wheel 3 and the pull rod 10 are installed on the two small shafts of the push plate 4, And can rotate around the small shaft; the trigger 11 is installed on the mounting plate 5 through its own small shaft,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com