Gas energy-saving recovery device

A recovery device and gas technology, applied in glass manufacturing equipment, glass furnace equipment, glass production, etc., can solve the problems of environmental pollution, waste, etc., and achieve the effect of good promotion and application prospects and significant emission reduction benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

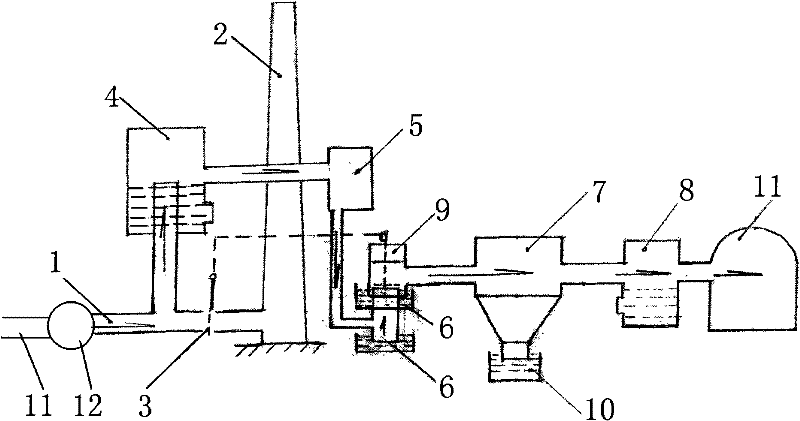

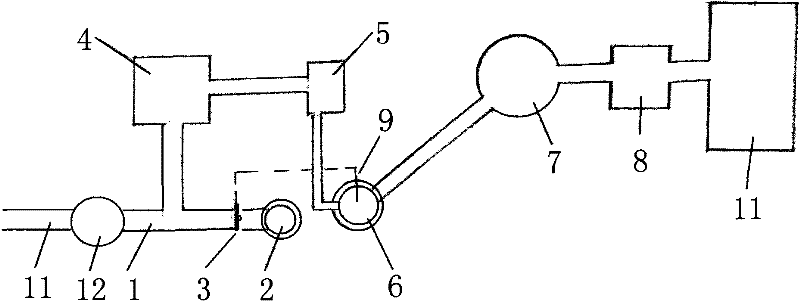

[0010] Accompanying drawing is a kind of specific embodiment of the present invention.

[0011] The gas energy-saving recovery device of the present invention includes a first gas flue 11, a gas exchanger 12, a second gas flue 1, and a chimney 2 connected in sequence, and a chimney inlet gate is set between the second gas flue 1 and the chimney 2 Plate 3, the second gas flue is connected to the first water sealing device 4, the induced draft fan 5, the second water sealing device 6, the gas storage tank 7, the third water sealing device 8 through pipelines before the chimney inlet gate, and the second The outlet of the third water sealing device is connected to the inlet of the first gas flue 11, the second water sealing device 6 is provided with a gas suction valve 9, and the bottom of the gas storage tank is provided with a fourth water sealing device 10. The size of the opening of the gas pipe and the chimney inlet valve plate is between 200X200mm and 2000X2000mm.

[0012]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com