Tobacco aerobic cracking analysis system

A sampling system and tobacco technology, which are applied in the preparation of test samples and other directions, can solve the problems of inability to realize online continuous cracking-injection mode, inability to simulate the combustion conditions of cigarettes well, and inability to achieve adsorption of cracked products, etc. Achieve the effect of real and reliable experimental data results, smooth transition, and continuous injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

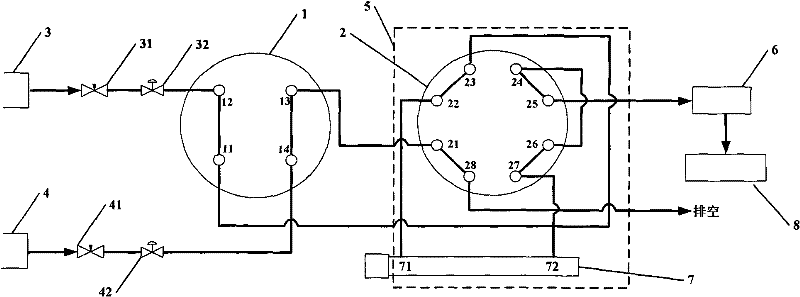

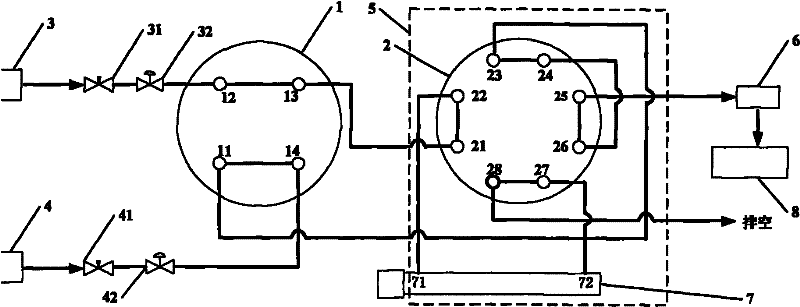

[0024] The invention discloses a tobacco aerobic cracking sample introduction system, the mechanism of which is as follows: figure 1 As shown, it includes a cracker, a mixed gas inlet 3 and an inert gas inlet 4, a cracking chamber 5 and a cracking pool 7 are arranged in the cracker, and an eight-way valve 2 is arranged in the cracking chamber 5. The mixed gas inlet 3 and the inert gas inlet 4 are connected to the eight-way valve 2 through a four-way valve 1 . Wherein the first valve port 11 of the four-way valve 1 communicates with the third valve port 23 of the eight-way valve 2, the second valve port 12 of the four-way valve 1 communicates with the mixed gas inlet 3, and the third valve port of the four-way valve 1 13 communicates with the first valve port 21 of the eight-way valve 2 , and the fourth valve port 14 of the four-way valve 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com