Tobacco aerobic cracking analysis method and sample injection system

An analysis method and a technology of sampling system, applied in the preparation of test samples, etc., can solve the problems that the online continuous cracking-sampling method cannot be realized, the combustion conditions of cigarettes cannot be well simulated, and the pyrolysis products cannot be adsorbed. , to achieve the effect of authentic experimental data results, smooth transition, and continuous sample injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

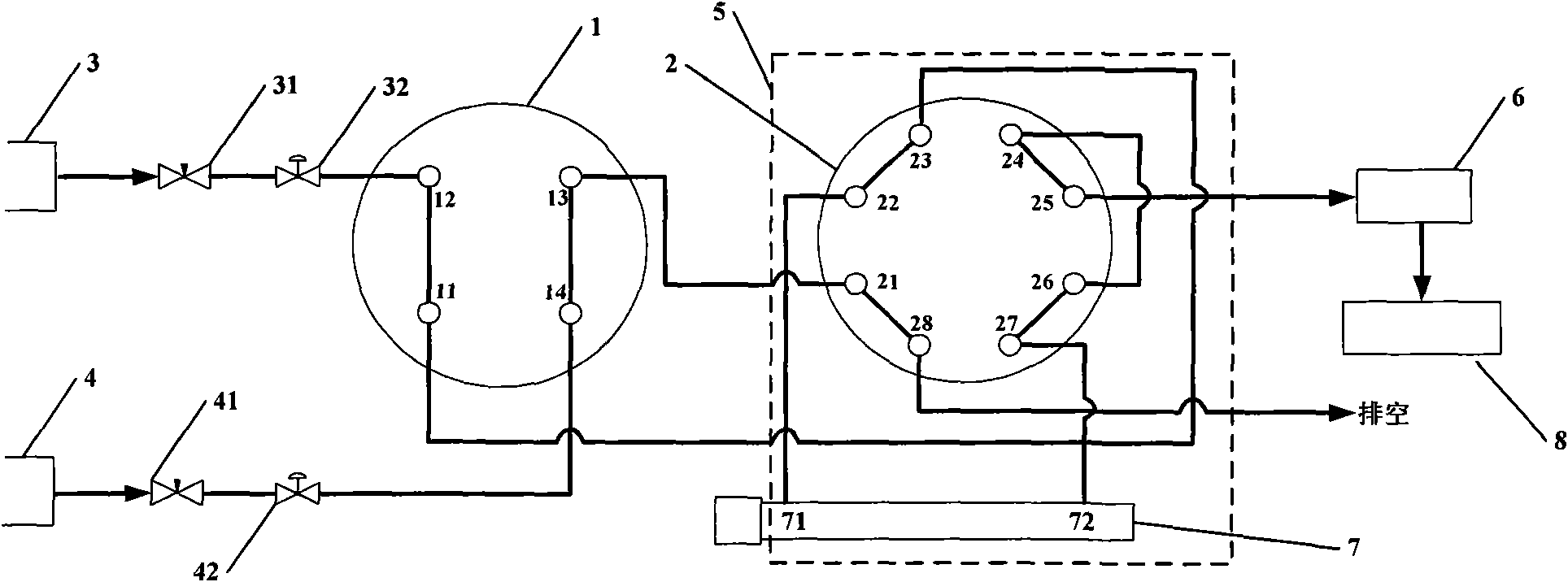

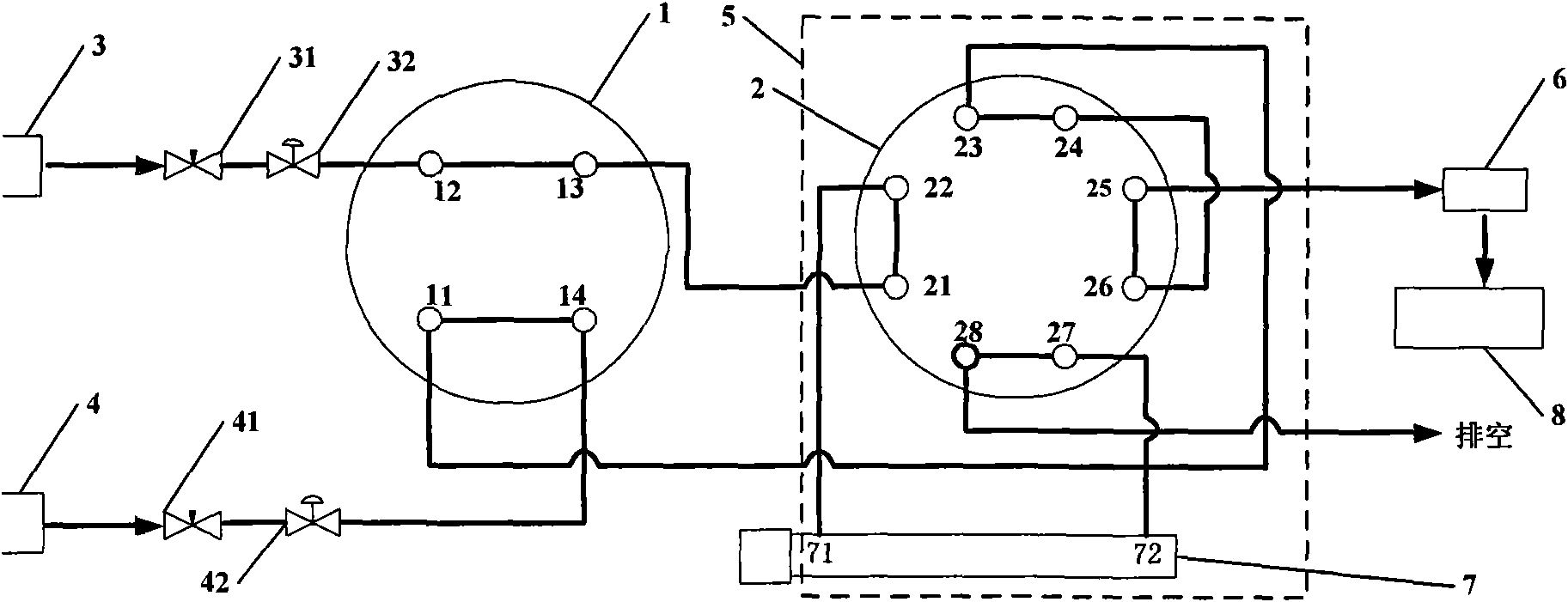

[0024] The invention discloses a tobacco aerobic cracking sample introduction system, the mechanism of which is as follows: figure 1 As shown, it includes a cracker, a mixed gas inlet 3 and an inert gas inlet 4, a cracking chamber 5 and a cracking pool 7 are arranged in the cracker, and an eight-way valve 2 is arranged in the cracking chamber 5. The mixed gas inlet 3 and the inert gas inlet 4 are connected to the eight-way valve 2 through a four-way valve 1 . Wherein the first valve port 11 of the four-way valve 1 communicates with the third valve port 23 of the eight-way valve 2, the second valve port 12 of the four-way valve 1 communicates with the mixed gas inlet 3, and the third valve port of the four-way valve 1 13 communicates with the first valve port 21 of the eight-way valve 2 , and the fourth valve port 14 of the four-way valve 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com