An apparatus for discharging pulp from a vessel, method of discharging pulp form a vessel and method of upgrading a pulp vessel

A technology of pulp and container, applied in the direction of papermaking, digester, textile and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

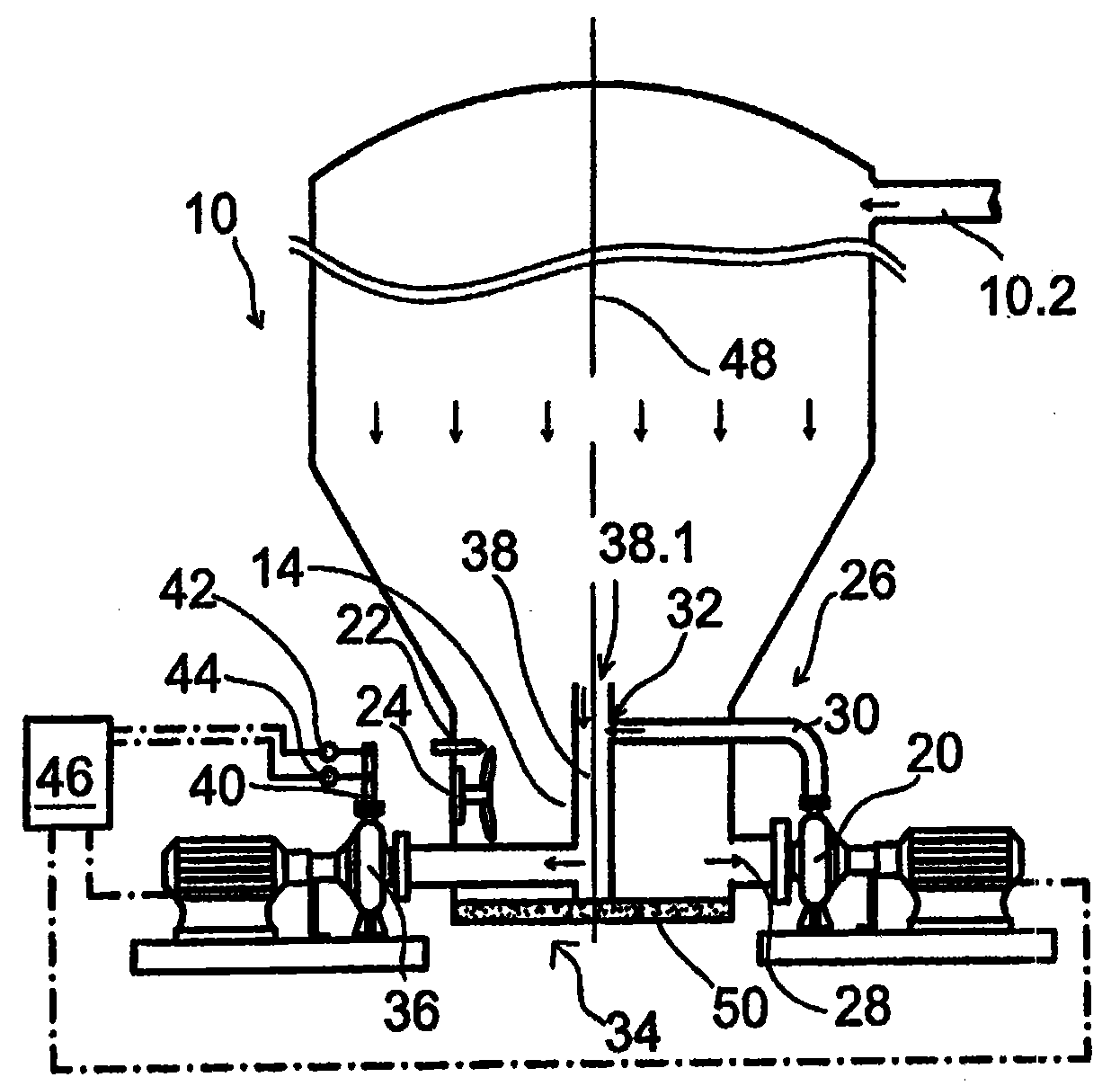

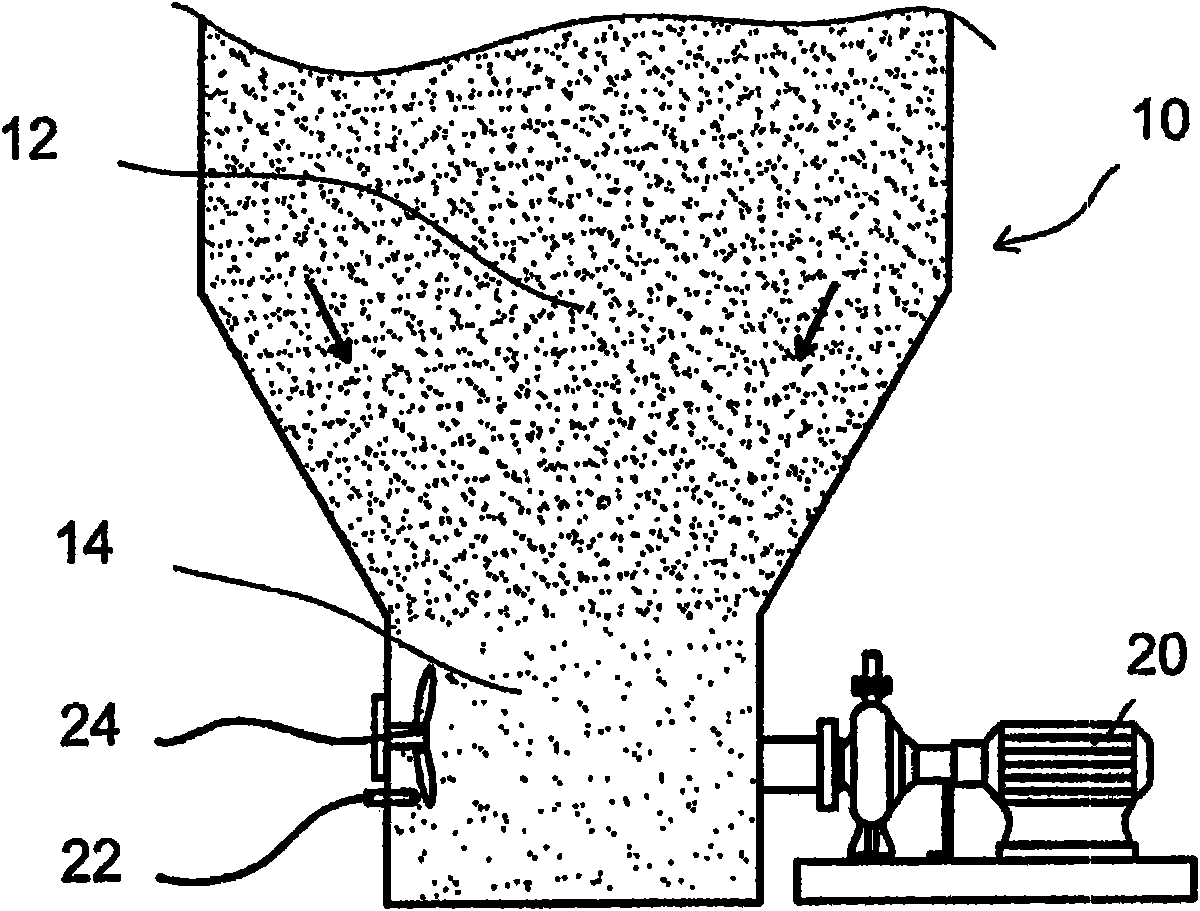

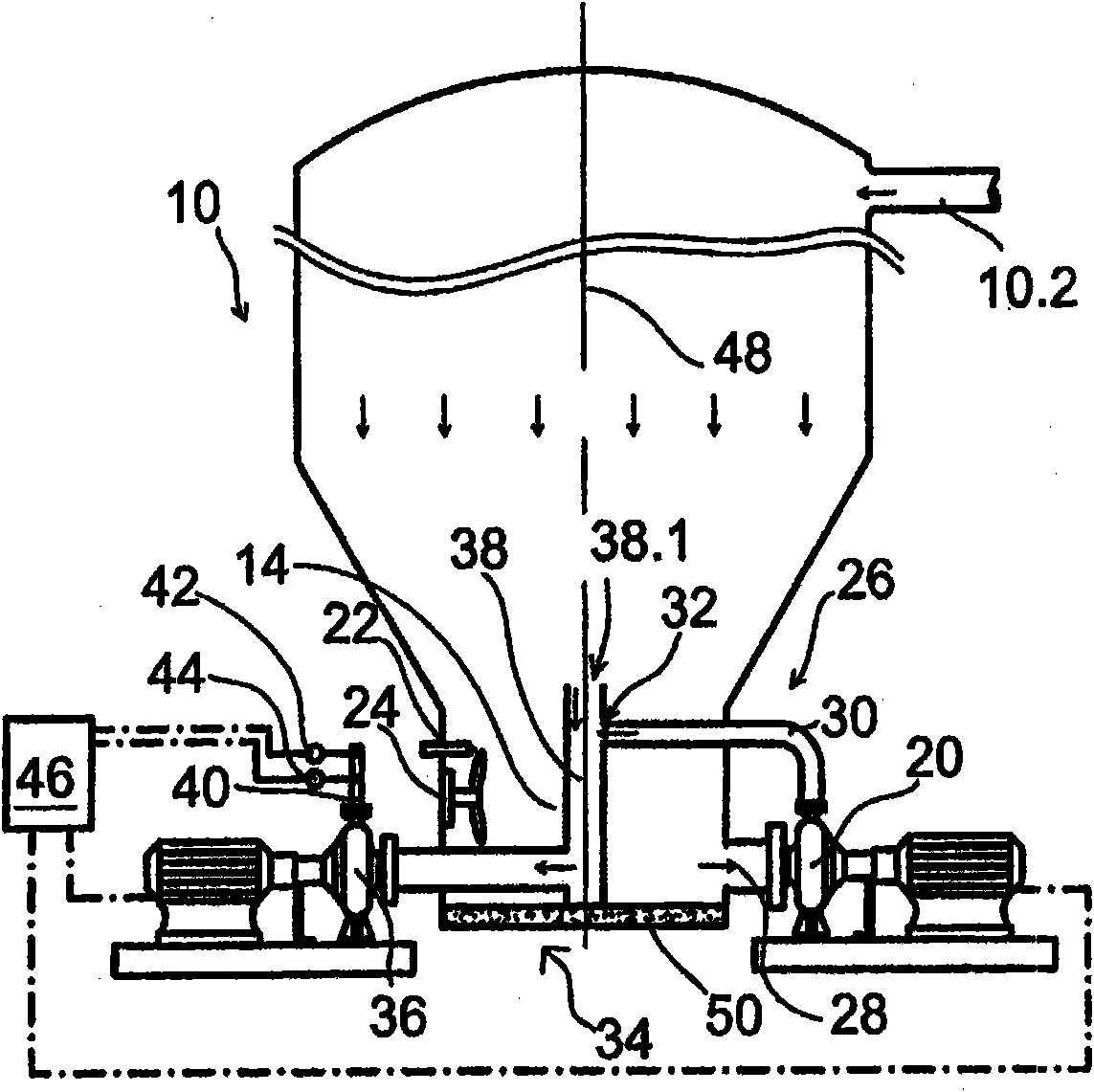

[0030] Figure 1 shows a modern discharge arrangement for a high consistency mass column according to the prior art. The high consistency mass tower 10 in the embodiment according to the figure comprises two parts: a second section, here the upper section 12 , and a first section, the bottom section 14 . Pulp at a first consistency is introduced into the upper section of the vessel, ie the second section (introduction not shown in the figure). The pulp may undergo additional treatment in the vessel, but may also be merely stored therein.

[0031] In the lower section there is provided a feed pipe 22 for introducing dilution liquid into the pulp. The tower also includes a stirrer 24 arranged in the bottom section for mixing the supplied dilution liquid with the pulp and keeping the pulp in a substantially homogeneous state. The lower section may also be referred to as a mixing zone. Thus, the consistency of the pulp in the bottom section 14 is generally maintained at a level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com