Fermentation grouting machine

A grouting machine and slurry technology, which is applied in bioreactor/fermenter combinations, bioreactors/fermenters for specific purposes, biochemical instruments, etc., can solve the problem of low efficiency of grouting food raw materials and cannot meet large-scale production operations , uneven weight addition and other problems, to achieve the effect of saving ingredients, fast grouting operation, and stable production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

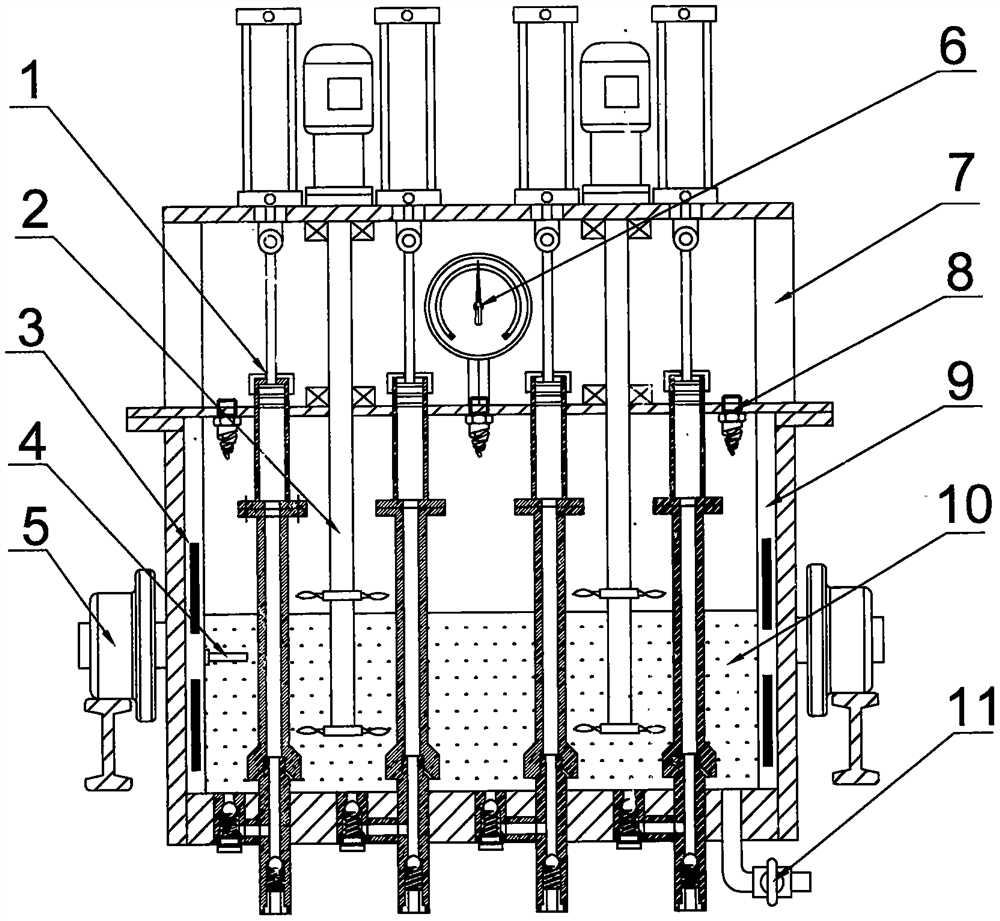

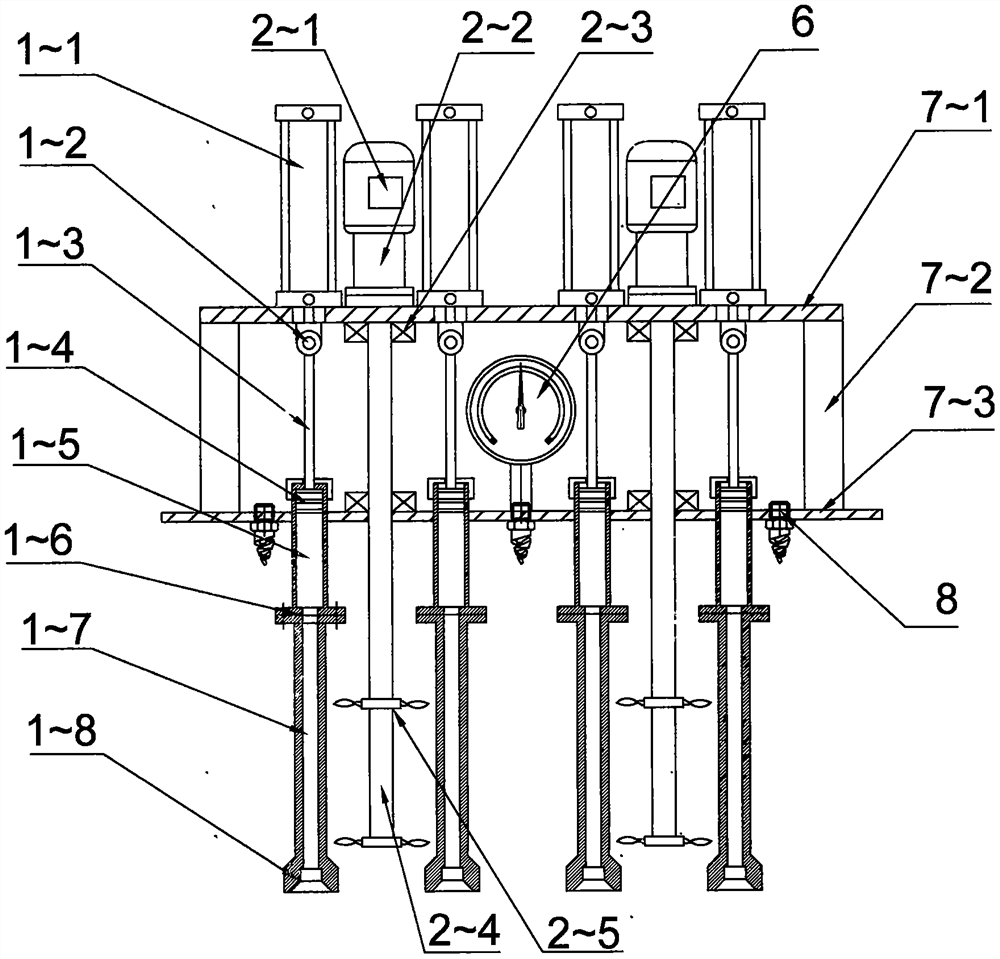

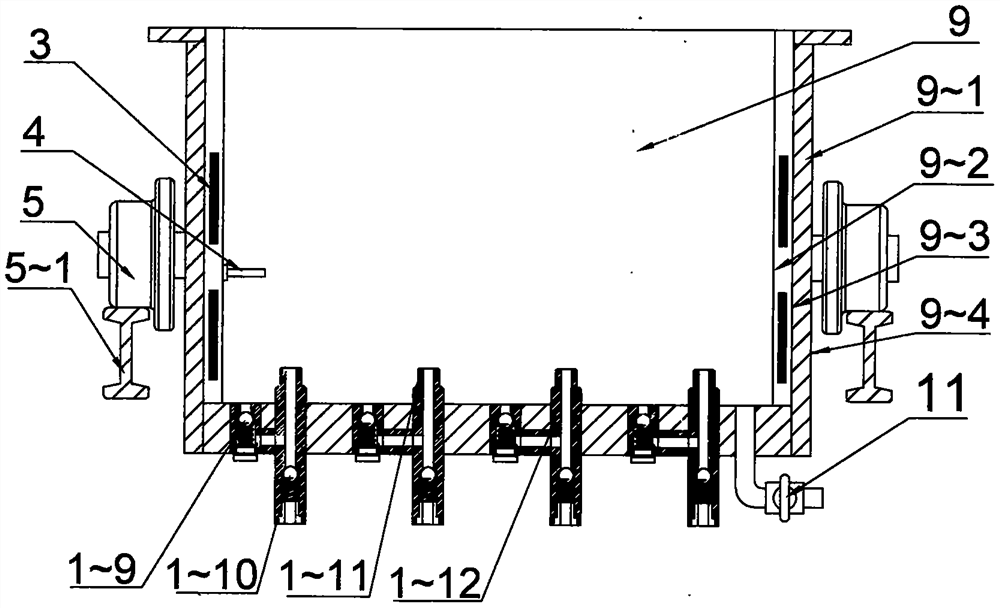

[0039] Example: in figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Among them, an invention of a fermentation grouting machine, including: suction grouting machine (1), mixer (2), electric heating tube (3), heat corner probe (4), roller (5), temperature controller (6) , frame (7), spiral nozzle (8), solution box (9) and drain valve (11); suction grouting machine (1) has cylinder (1~1) flexible head (1~2) piston Rod (1~3), piston head (1~4), piston cavity (1~5), flange joint (1~6), connecting cylinder (1~7), cylinder interface (1~8), suction Valve (1~9), grouting valve (1~10), O-ring (1~11), valve body (1~12), spring (1~13) and grouting nozzle (1~14); mixer (2) It consists of motor (2~1), reducer (2~2), support bearing (2~3), stirring shaft (2~4) and impeller (2~5); the roller (5) is on the track ( 5~1) can slide; the frame (7) has a frame upper plate (7~1), pillars (7~2) and frame lower plate (7~3); the spiral nozzle (8) has a high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com