Coating agent for paper containing vinyl alcohol polymer, paper coated therewith, and heat-sensitive paper

一种涂层剂、乙烯醇的技术,应用在纸和热敏纸领域,达到耐水性优异、黄变少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

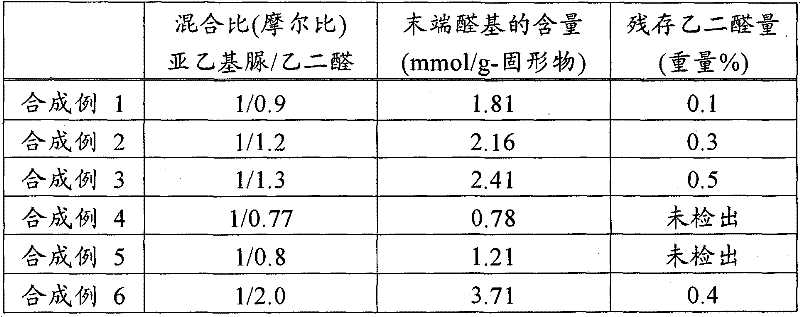

Synthetic example 1

[0063]Add 86 parts of ethylene urea to a 4-necked flask equipped with a reflux condenser, a thermometer and a stirring device, add 129 parts of water and 130.5 parts of glyoxal solution with a concentration of 40% (equivalent to "ethylene urea in molar ratio) : glyoxal=1: 0.9 "), use the sodium hydroxide solution of concentration 10% as pH adjuster after the pH value of system is adjusted to 7, make ethylene urea and glyoxal react 10 hours at 60 ℃. After the reaction was completed, it was matured at 35°C for 16 hours, and then, while the temperature of the system was cooled to below 30°C, the pH value of the system was adjusted to 6 by using a 20% sulfuric acid solution. This gives a pale yellow transparent solution containing the addition condensate formed by ethylene urea and glyoxal. In addition, the solid content concentration of the above-mentioned addition condensate in this solution was 40%.

[0064] The average molecular weight of the addition condensate obtained as d...

Embodiment 1

[0106] 90 g of aluminum hydroxide powder (manufactured by Showa Denko Co., Ltd., Hijilite H42) was added to 210 g of distilled water, and after stirring by hand, it was stirred at a rotation speed of 13,500 rpm for 5 minutes using a homogenizer (manufactured by IKA-Labortechnik, model T-25-SI). , Prepare aluminum hydroxide dispersion A (30% aluminum hydroxide concentration).

[0107] In addition, PVA-1 was dissolved in hot water at 95°C, and a 10% PVA aqueous solution was prepared separately.

[0108] Then, the PVA aqueous solution 60g is joined in the dispersion liquid A of 22g, after uniformly mixing both, add the addition condensate of synthesis example 1 again, make PVA:addition condensate (solid matter weight ratio)=90:10, Mix evenly, add distilled water until the solids concentration is 15%, to obtain a coating agent (Example 1). The viscosity of the obtained coating agent was measured with a B-type viscometer at a temperature of 20° C. and a rotation speed of the inner...

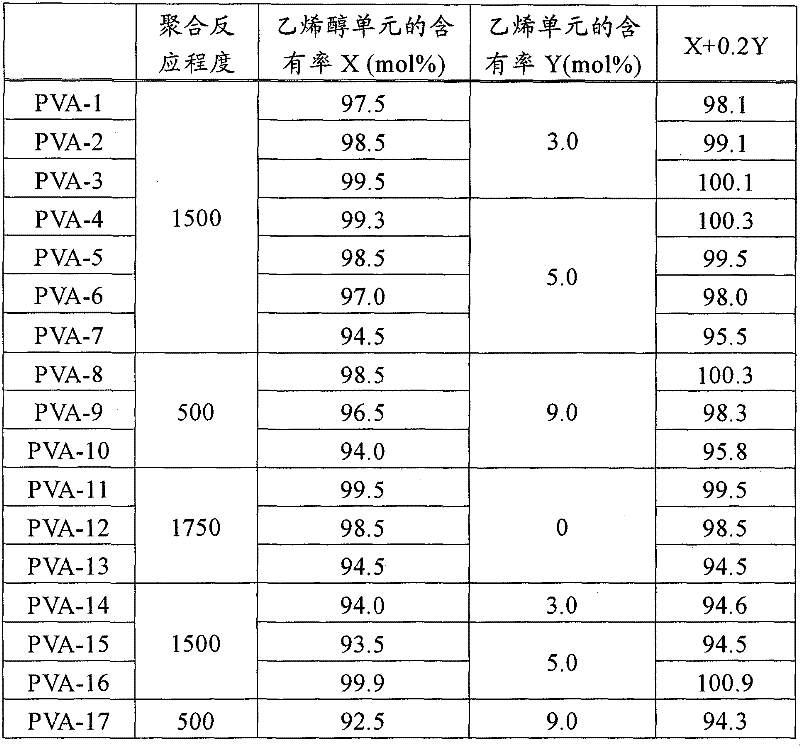

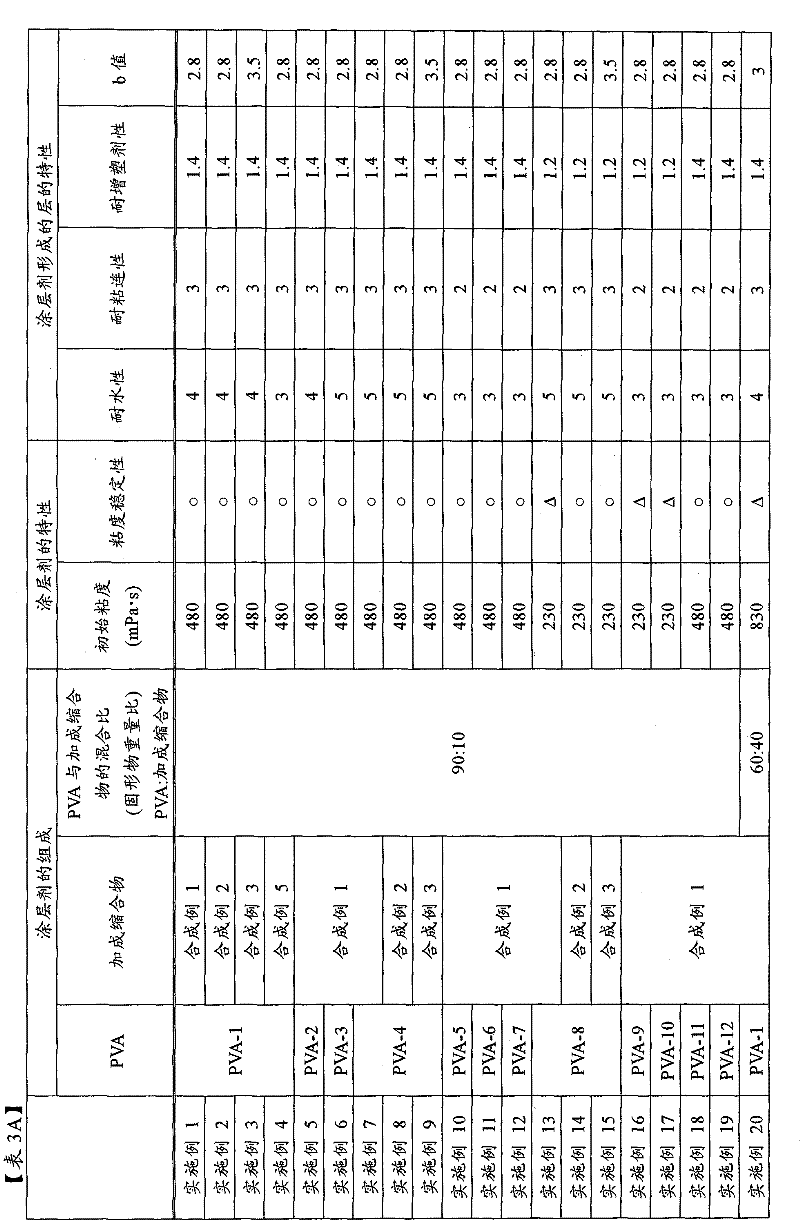

Embodiment 2~20、 comparative example 1~10

[0136] The addition condensates formed in Synthesis Examples 1 to 6 and PVA-1 to PVA-17 and Example 1 are mixed according to the ratios shown in the following Table 3A and Table 3B to obtain the coating agent (Examples 2 to 20, Comparative Examples 1-10). Furthermore, in Comparative Example 8, glyoxal was used instead of the addition condensate as the crosslinking agent.

[0137] The viscosity stability of the obtained coating agent and the characteristics of the layer formed by the coating agent were evaluated in the same manner as in Example 1. The evaluation results are shown in Table 3A and Table 3B below.

[0138]

[0139]

[0140] As shown in Table 3A and Table 3B, in Examples 1 to 20 related to the coating agent of the present invention, the viscosity stability and various properties of the layer formed using the coating agent can be expressed at a high level and in a good balance.

[0141] In addition, in Examples 1 to 20, especially in Examples 6 to 9 and 13 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com