High-voltage square-wave pulse power source for sterilizing liquid foods

A square wave pulse and liquid food technology, which is applied in food preservation, application, food science, etc., can solve the problems of high technical difficulty and high cost, and achieve the effects of cost reduction, small cell membrane breakdown, and self-protection

Inactive Publication Date: 2010-08-25

DALIAN UNIV OF TECH

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is to provide a high-voltage square-wave pulse power supply for liquid food sterilization, which solves the problems of high cost and technical difficulty of the existing high-pressure sterilization power supply

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

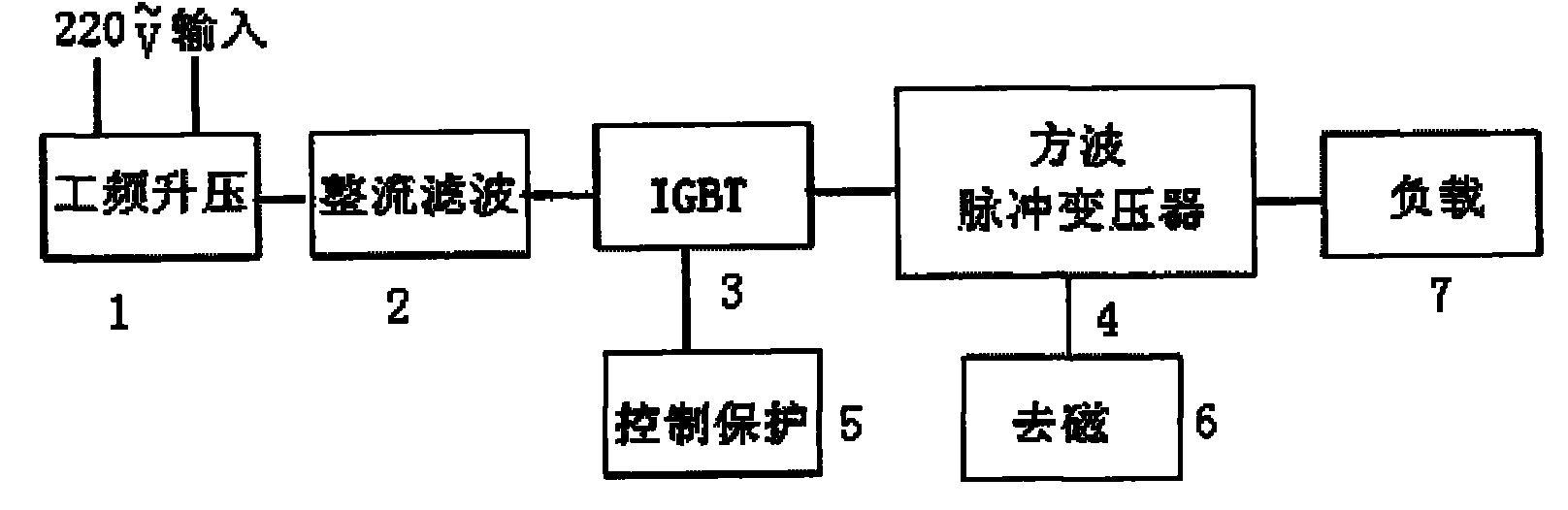

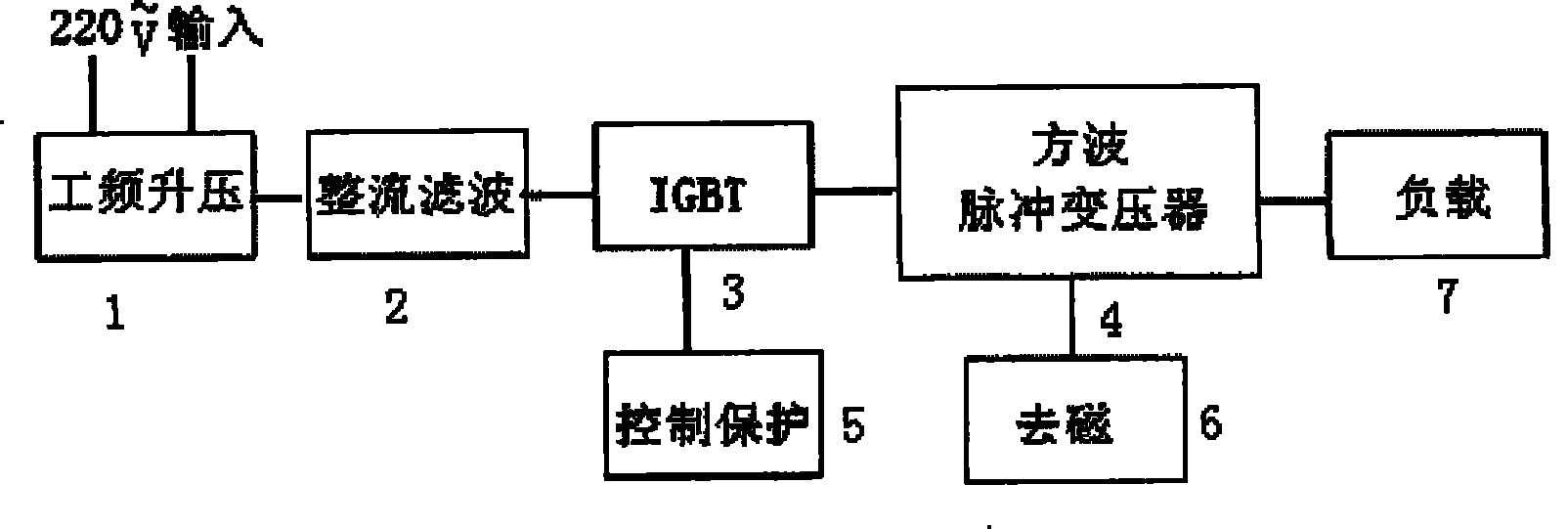

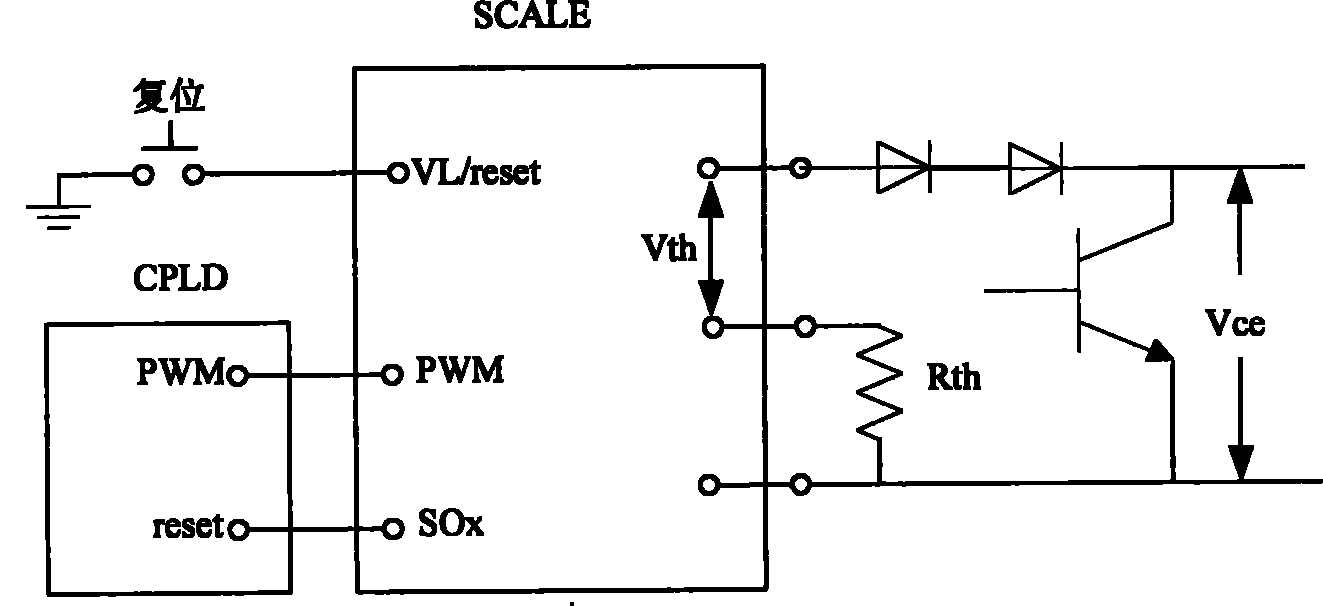

The invention discloses a high-voltage square-wave pulse power source for sterilizing liquid foods, which belongs to the technical field of high-voltage processing application. The power source is characterized in that a whole system comprises a voltage-boosting unit, a rectifying-filtering unit, a switching device, a square-wave pulse transformer, a control protection unit and a demagnetization unit; 220V power-frequency voltage is connected to the rectifying-filtering unit through the voltage-boosting unit and is input into the square-wave pulse transformer through the turn-on and turn-off of IGBT so as to obtain pulsed high voltage on a load; the control protection unit is connected with the IGBT; and the demagnetization unit is connected with the square-wave pulse transformer. The power source has the advantages of obtaining a square-wave pulse source which allows load parameters to be changeable in a wide range, has the front edge of pulse at a submicrosecond level and has the voltage more than ten kV or tens of kW, greatly reducing cost and giving consideration to medium strength, cell membrane breakdown and non-thermal effect with minimum energy. As liquid foods are taken as the load incapable of avoiding electric discharge and interference in equipment, the power source can realize the self-protection of the equipment.

Description

A high-voltage square-wave pulse power supply for liquid food sterilization technical field The invention belongs to the technical fields of high-voltage technology, bioengineering and agricultural product processing, and relates to a high-voltage square-wave pulse power supply for liquid food sterilization. Background technique In order to make up for the shortcomings of traditional thermal sterilization methods and meet people's needs for food color, aroma, taste and nutritional components, some food medium temperature does not rise or rises very little, and can quickly and effectively kill the existing Harmful microorganisms in food and energy-saving non-thermal sterilization technology have emerged as the times require, and are receiving more and more attention. Since the 1980s, foreign research on the application of non-thermal sterilization technology in the food industry has entered a climax, including ultra-high pressure sterilization, membrane separation technolog...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23L3/32

Inventor 邹积岩王仁丽董恩源陈锦权

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com