Method of supplying melting metal to the automatic pouring machine and device thereof

A molten metal, automatic pouring technology, applied in the direction of molten metal supply equipment, metal processing equipment, casting equipment, etc., can solve the problems of increasing the amount of molten metal in the ladle, increasing the number of molds to be poured, and difficult storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

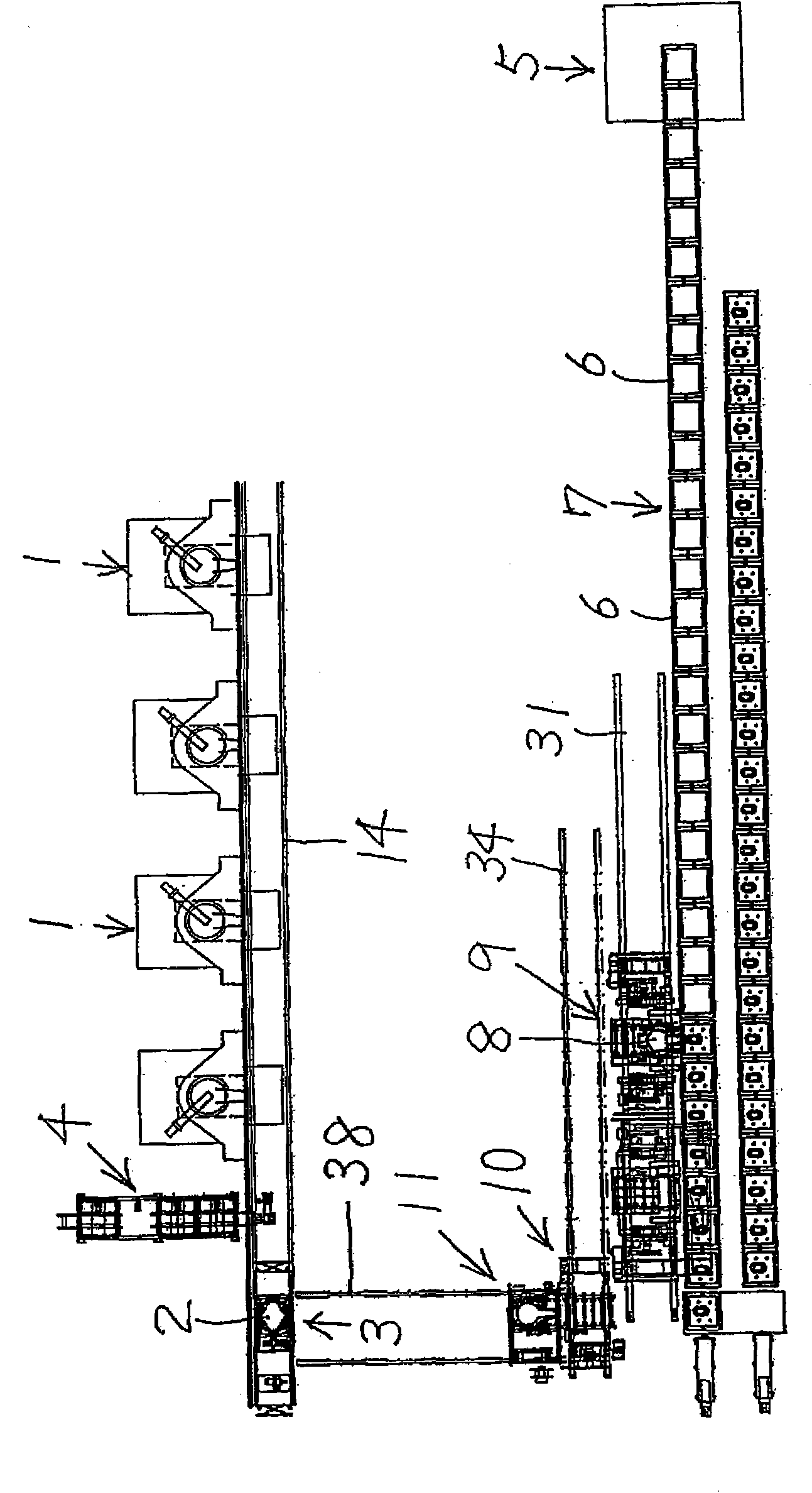

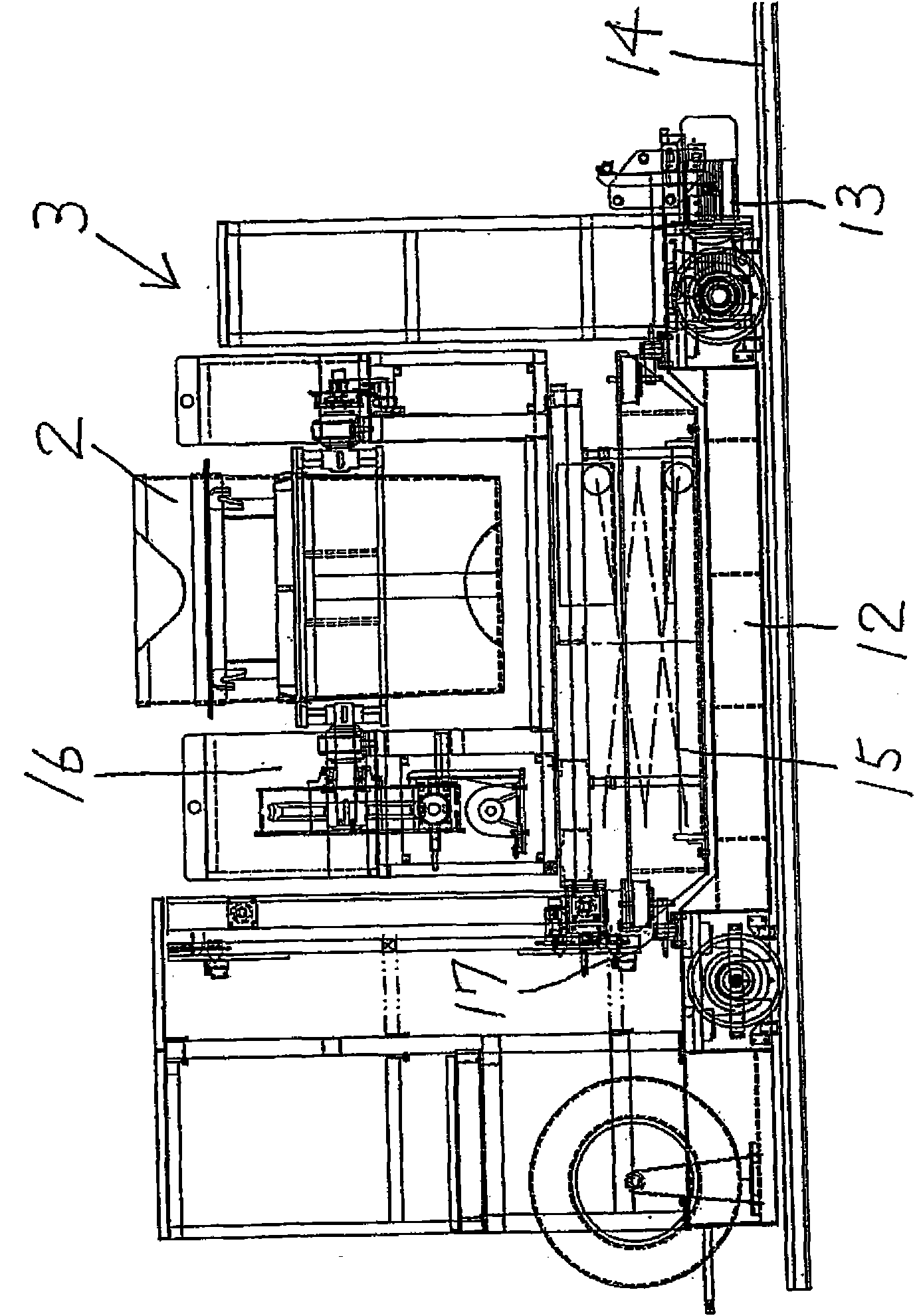

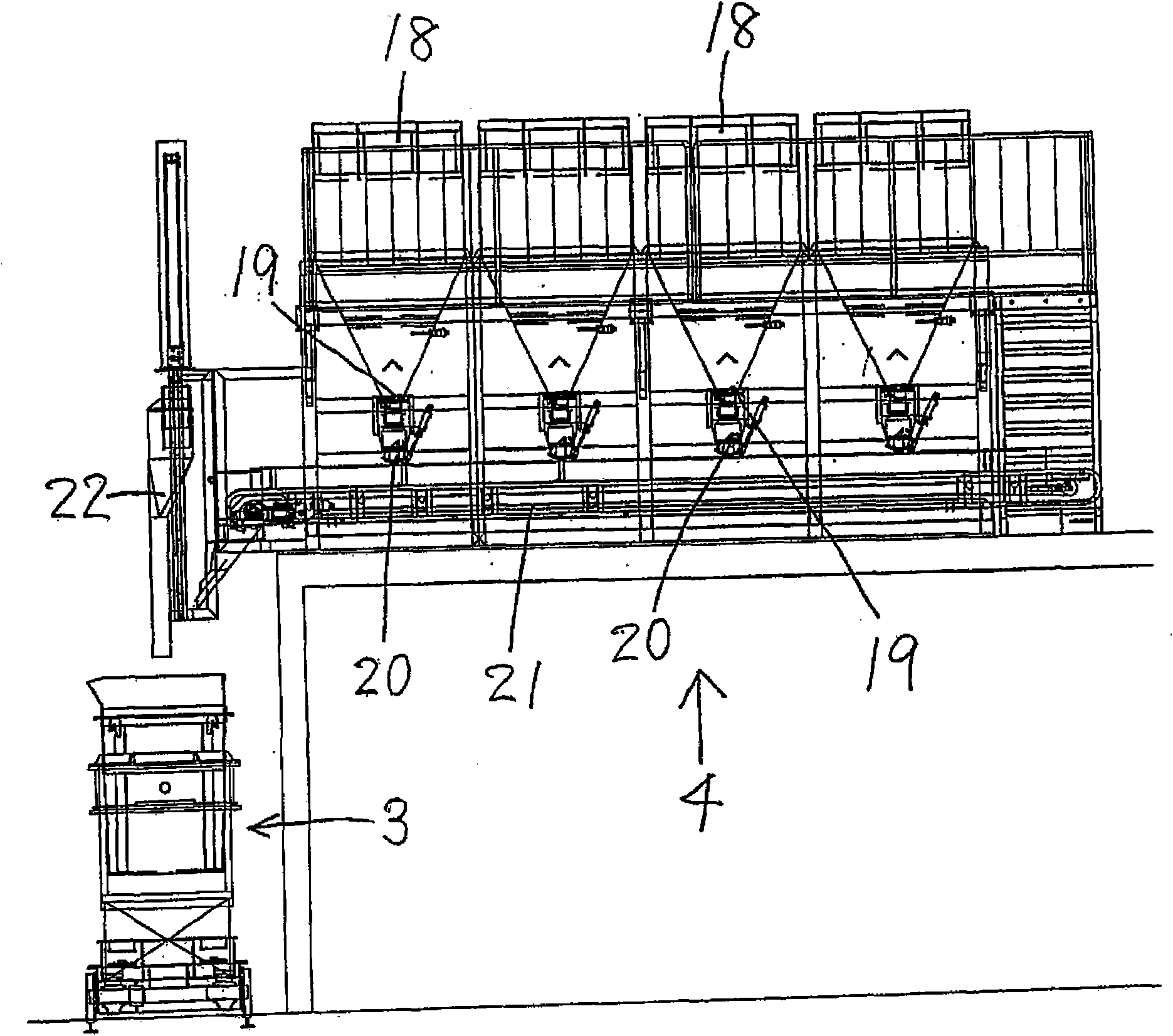

[0016] Below, combine Figure 1 to Figure 6 An example of casting equipment to which the present invention is applied will be described in detail. Such as figure 1 As shown, the structure of this casting equipment includes: a plurality of melting furnaces 1·1, which are arranged in parallel with the molding line 7 and arranged in a row along the left and right directions together with the alloy component material input device 4; processing ladle handling trolley 3 , which accepts and temporarily stores the processing ladle 2 from each melting furnace 1 into and out of the position of each melting furnace 1; the alloy component material input device 4, which is adjacent to the melting furnace 1 at the left end, is provided to the Processing ladle 2 drops into alloy component material; Molding mold line 7, it is constituted that casting box 6 built-in casting mold is sent out from mold molding machine 5 in a row; 6 groups of casting boxes move synchronously, and have pouring l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com