Power tool

A technology of electric tools and electric current, which is applied in the direction of motor tools, manufacturing tools, striking tools, etc., can solve the problem of reducing operating force, and achieve the effect of reducing component load and operating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

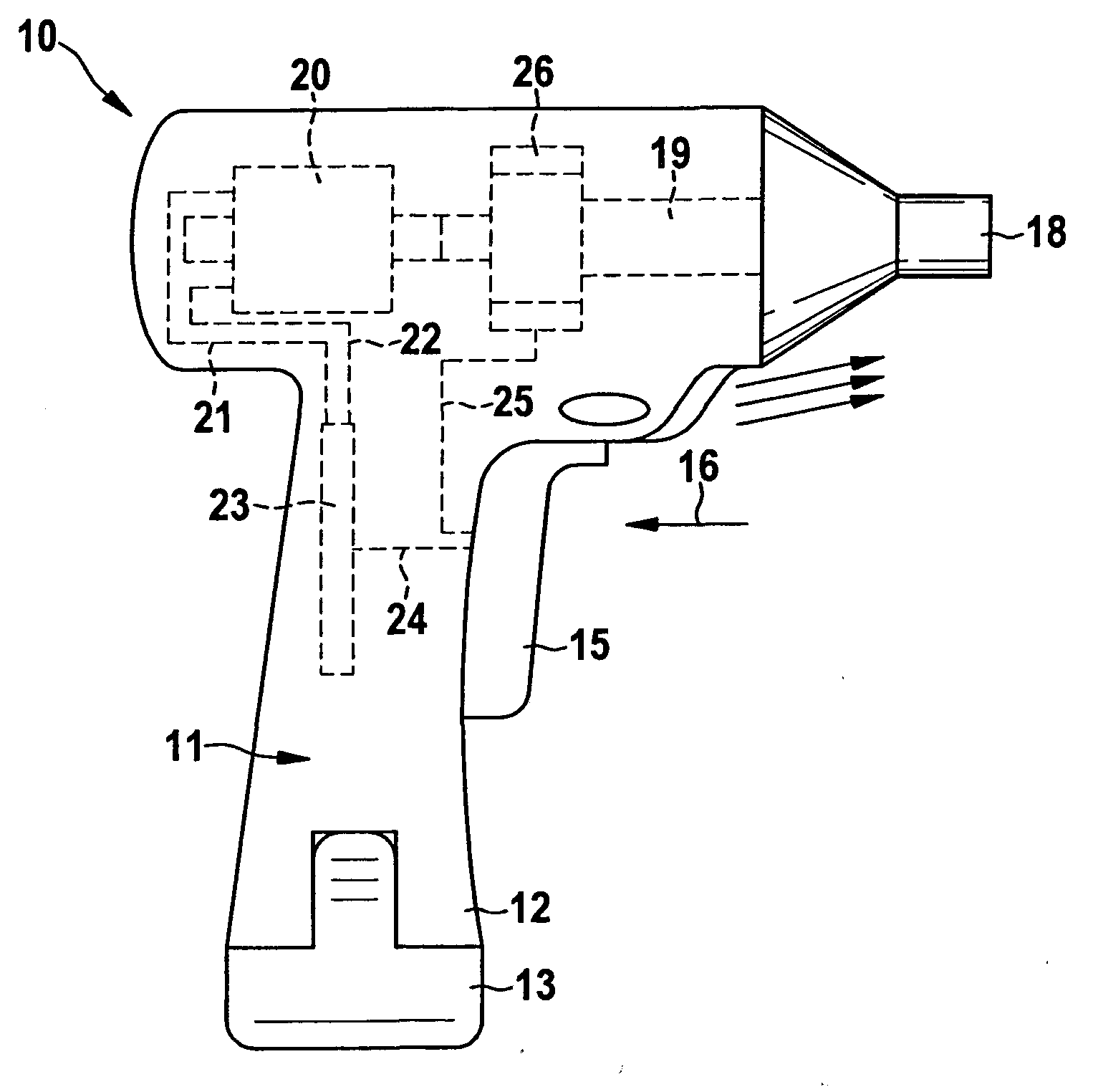

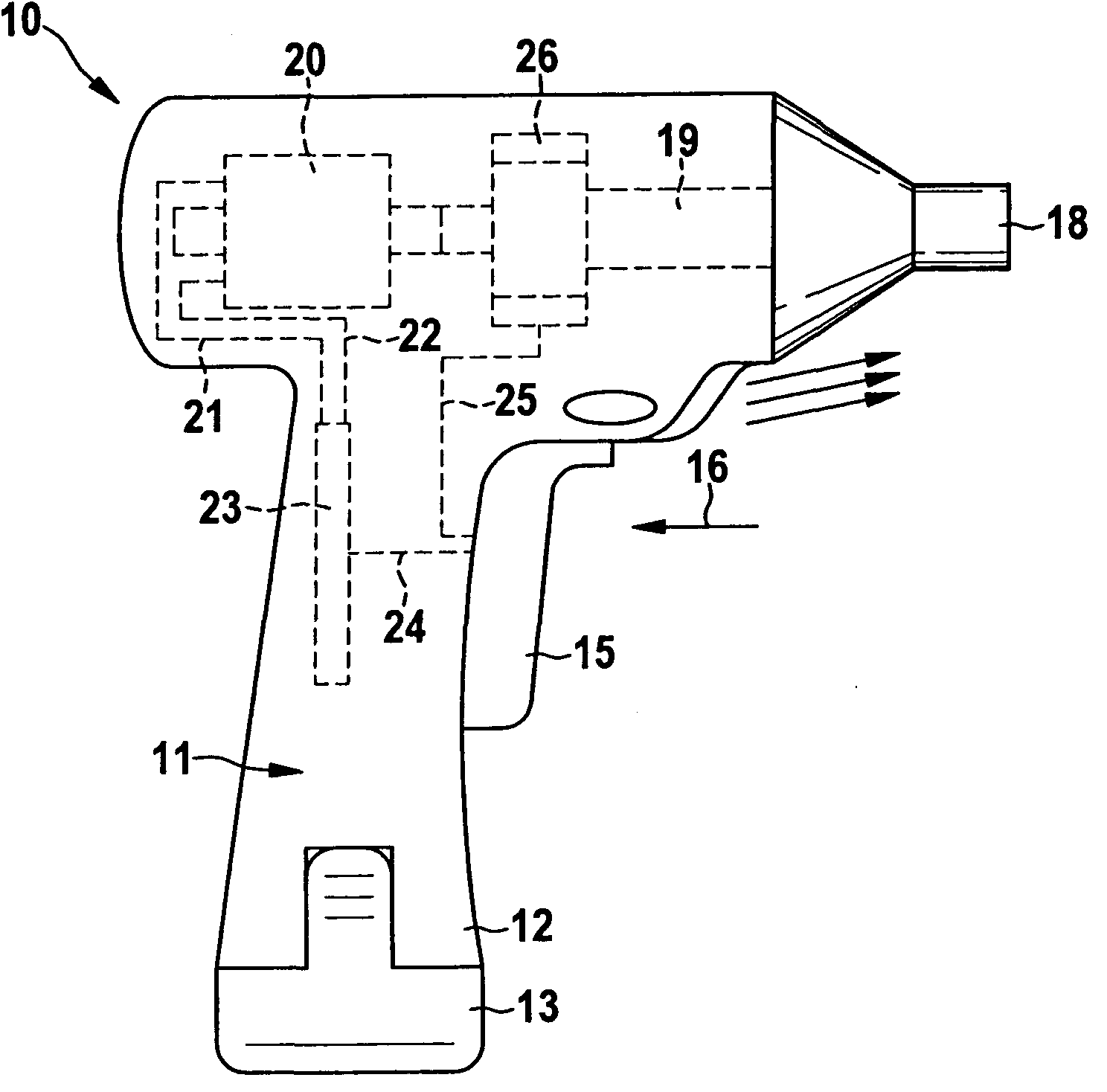

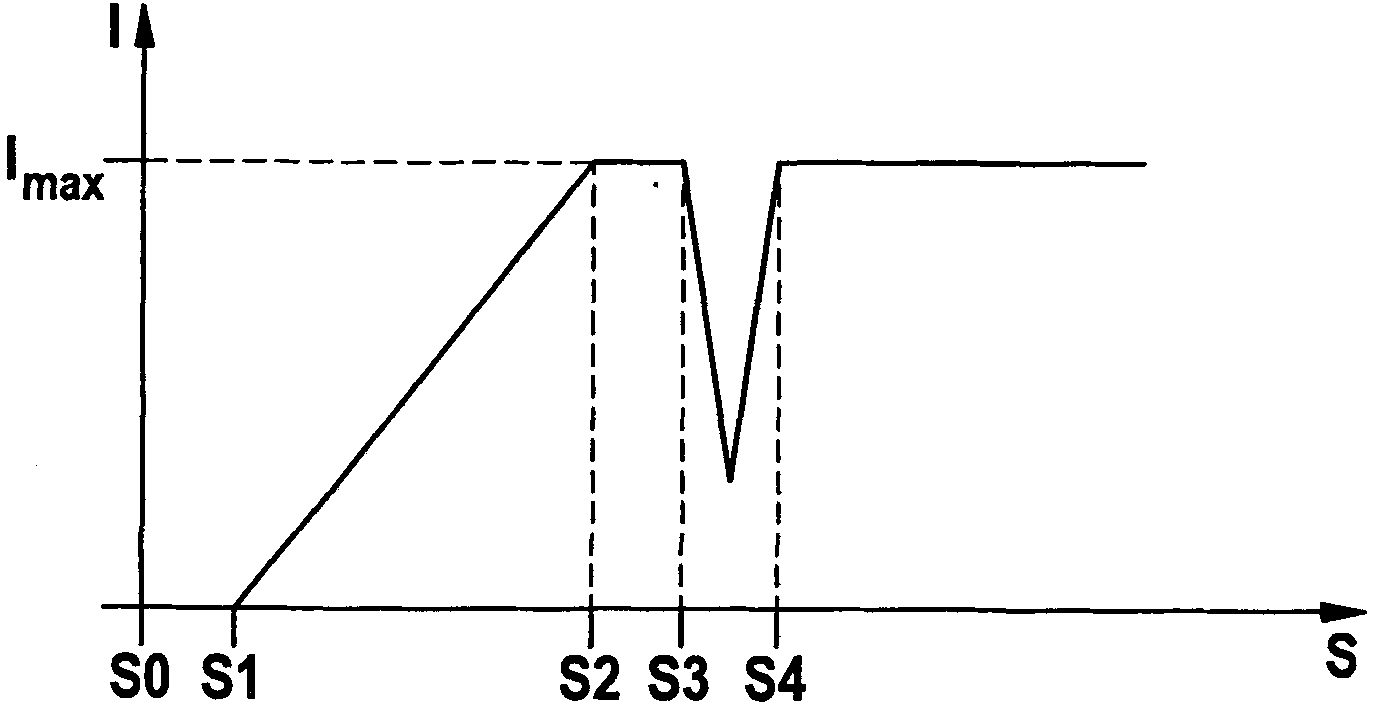

[0019] FIG. 1 shows a hand drill 10 which has a housing 11 . It can also be seen that at the lower end of the handle 12 there is a battery pack 13 which is used as an energy source for the drive (motor) of the hand drill 10 and for the electronics. Also mounted on the handle 12 is a switching pawl 15 which can be moved by the operator in the direction of the arrow 16 . Furthermore, the movement of the switching pawl 15 in the direction of the arrow 16 is also denoted as the movement path S of the switching pawl 15 .

[0020] The hand drill 10 internally has a drive motor 20 which is coupled via a transmission to the drill holder 18 or the spindle. The driving motor 20 is connected to the power control switch 23 through the lines 21 and 22 , and the power control switch 23 is connected to the switch pawl 15 through the line 24 or controlled and activated by the switch pawl 15 .

[0021] The switching pawl 15 is additionally connected via a connecting device 25 to an automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com