Membrane filter board compression molding device and molding method

A technology of compression molding and diaphragm filter plate, which is applied in the direction of household components, household appliances, other household appliances, etc. Reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

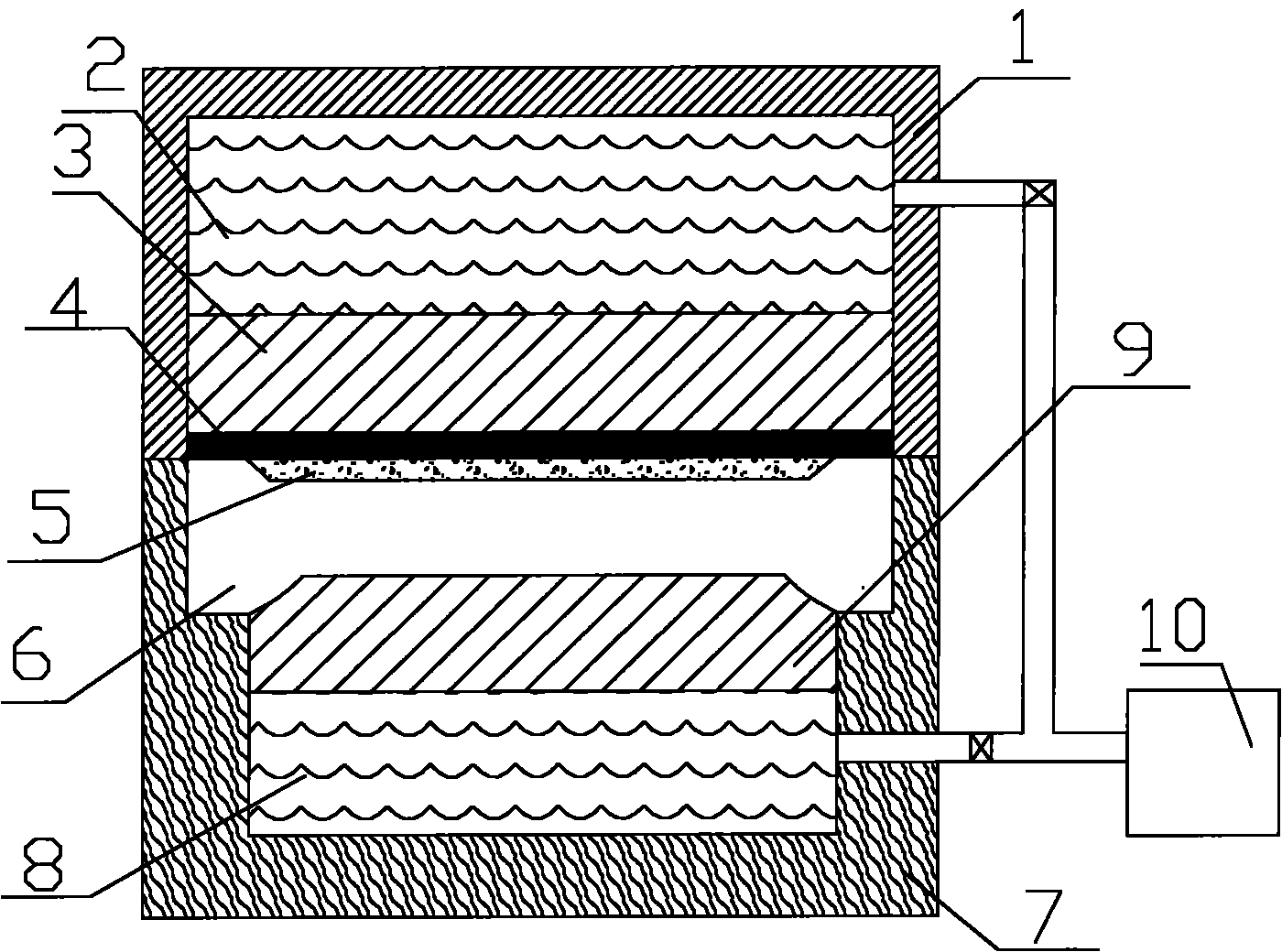

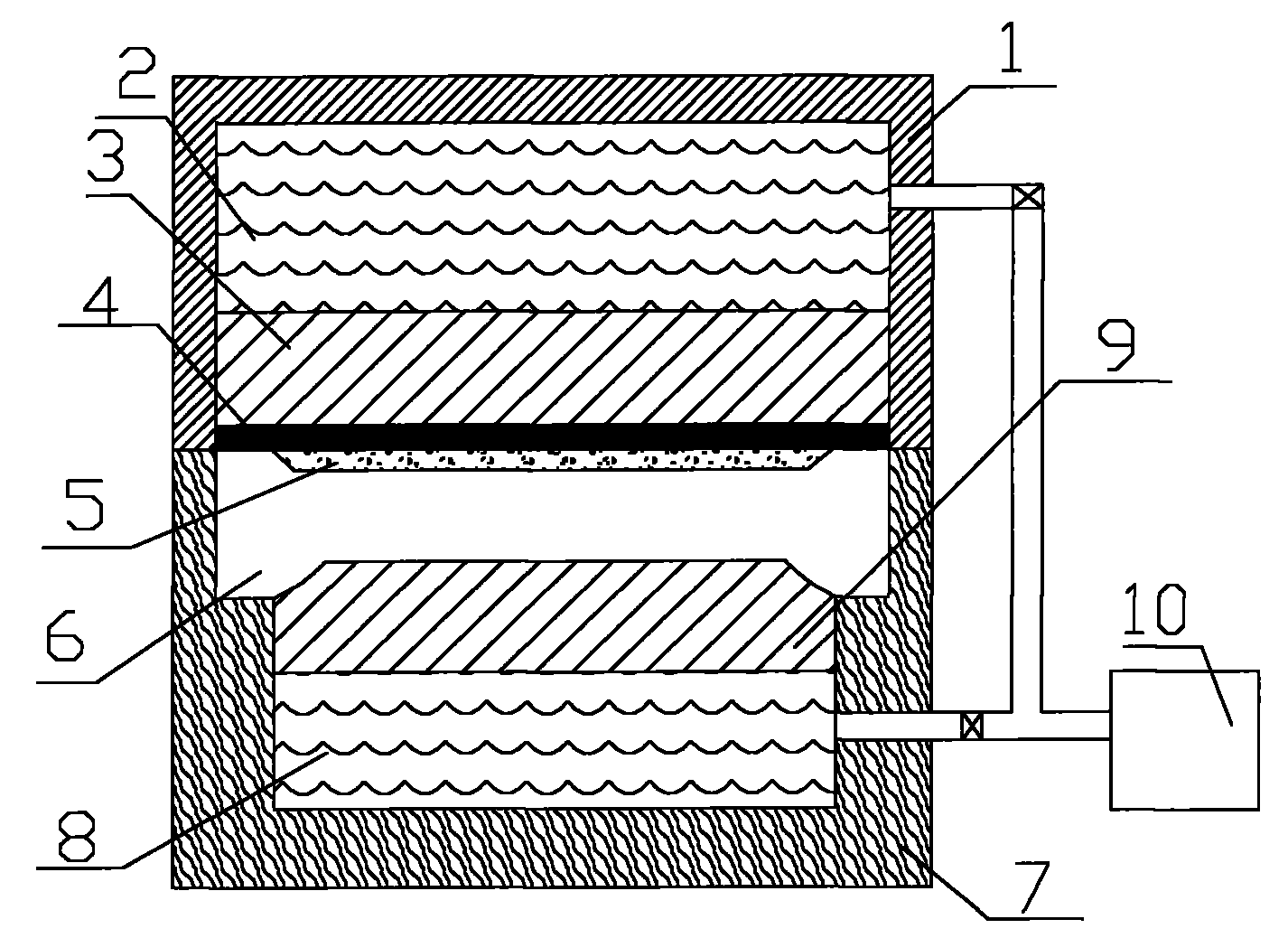

[0009] Embodiment 1: with reference to attached figure 1 . Diaphragm filter plate molding device, which includes an upper mold and a lower mold, the upper mold is an oil cylinder type upper mold 1 and the cavity 4 of the oil cylinder type upper mold 1 is a diaphragm forming cavity, and the forming surface 3 of the diaphragm forming cavity is an oil cylinder piston surface And the oil cylinder piston is located in the upper mold oil chamber 2; the lower mold 7 is composed of a filter plate 6 and a lower mold oil cylinder, one side of the filter plate 6 is in contact with the piston 9 in the lower mold oil cylinder, and the other side is the mold surface of the lower mold; The upper mold oil chamber 2 and the piston chamber 8 communicate with the hydraulic station 10 through the oil delivery pipe. The four sides of the filter plate 6 are in contact with the table surface of the supporting boss of the cylinder wall of the lower mold. The surface of the piston 9 coincides with t...

Embodiment 2

[0010] Embodiment 2: Diaphragm filter plate molding method, filter plate 6 one side is put into the table top of the support boss of lower die oil cylinder cylinder wall, lower die oil cylinder works and makes piston 9 in the lower die oil cylinder face the groove surface of filter plate Put the degradable mold core 5 into the other side of the filter plate, then put the plasticized plastic ball on the degradable touch mold core 5, at this time, command the cylinder type upper mold 1 to move down, and press the heated plastic ball Combined with the other side of the filter plate 6, a single-sided plastic diaphragm filter plate is formed after cooling. The degradable mold core 5 is paper or hydrolyzed material or hydrolyzed release agent. The pressures bear between the piston 13 and the piston 9 are equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com