Compressor concentrated amendment

A conditioner and compressor technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of corrosion, danger, and incompleteness of compressors, and achieve the effects of good lubricity, safe use, and extended service life

Inactive Publication Date: 2010-08-25

益田润石(北京)化工有限公司

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the mineral type compressor oil sold on the market will have more or less paint film and carbon deposits during high temperature use. The amount will affect the normal operation of the compressor. At this time, the compressor needs to be disassembled and cleaned.

At present, there are several ways to clean the compressor in China: 1. Clean with kerosene or diesel oil, which can catch fire, which is very dangerous; 2. Chemical cleaning. Chemical cleaning agents corrode the compressor and decompose the compressor oil; 3. Mechanical cleaning is not thorough and the effect is not obvious; 4. Disassembly and cleaning is time-consuming and expensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

Login to View More

Abstract

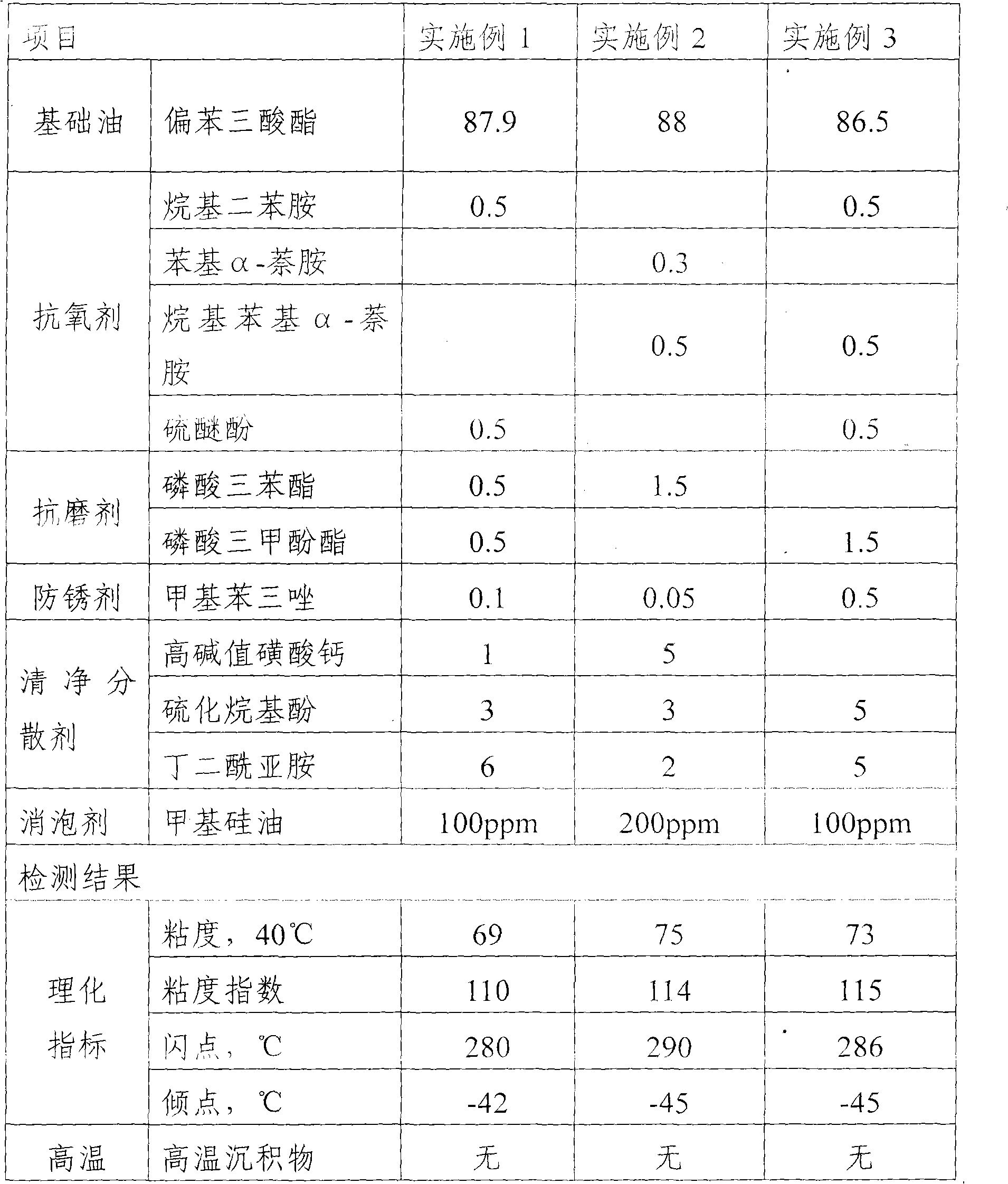

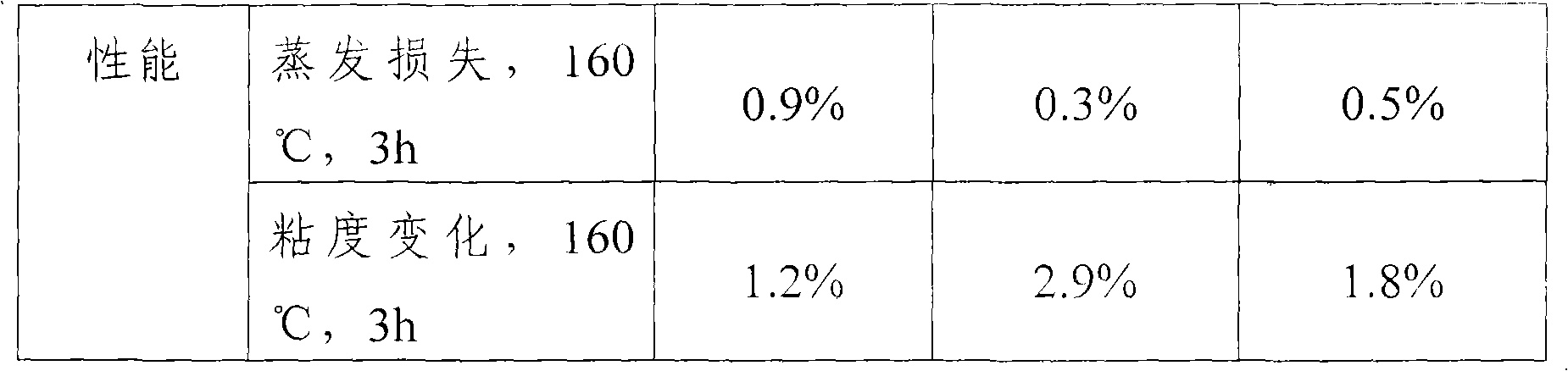

The invention relates to a synthetic ester oil-based compressor concentrated amendment, which comprises the following components in percentage by weight: (1) 70 to 98 percent of synthetic ester base oil, (2) 0.5 to 5 percent of high-temperature antioxidant, (3) 0 to 3 percent of extreme pressure anti-wear additive, (4) 0.01 to 1 percent of anticorrosive agent, (5) 1 to 15 percent of high-temperature detergent dispersant, and (6) 0.01 to 1 percent of antifoaming agent. The compressor concentrated amendment is prepared at the temperature of between 80 and 95 DEG C, and additives are added and uniformly dissolved in turn. The compressor concentrated amendment is convenient to use, has a solvent action to paint films and carbon depositions generated by a compression system of a compressor, and disassembling cleaning is saved if the compressor concentrated amendment is used periodically.

Description

technical field The invention relates to a concentrated conditioner for a compressor, in particular to a conditioner applied to remove paint film and carbon residue inside a compressor system. technical background Air compressor is a general-purpose machine widely used in various fields of national economy and industry. Its consumption and production volume are equal. my country's annual consumption of compressor oil is nearly 100,000 tons, of which more than 80% are lubricated with mineral oil-type compressor oil. At present, the mineral type compressor oil sold on the market will have more or less paint film and carbon deposits during high temperature use. The amount will affect the normal operation of the compressor, then the compressor needs to be disassembled and cleaned. At present, there are several ways to clean the compressor in China: 1. Clean with kerosene or diesel oil, which can catch fire, which is very dangerous; 2. Chemical cleaning. Chemical cleaning agen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10N30/04C10N30/10

Inventor 李刚曾玉芬杜守琴王金波

Owner 益田润石(北京)化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com