Concrete shear wall with once-molded filling wall and manufacturing method thereof

A technology for concrete shear walls and infill walls, applied to walls, structural elements, building components, etc., can solve problems affecting construction progress, affecting use requirements, and prone to cracks, etc., to achieve simplified construction process, reliable connection, and economical construction effect of funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

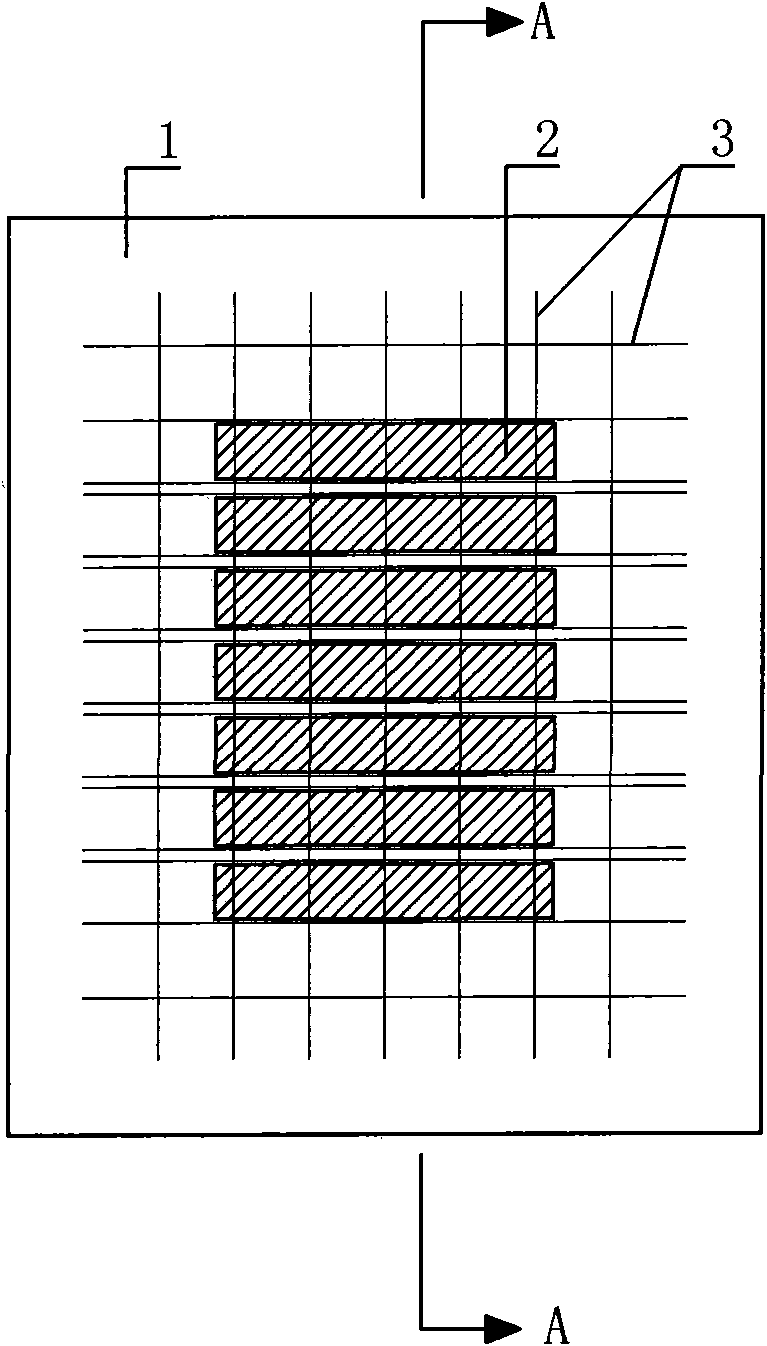

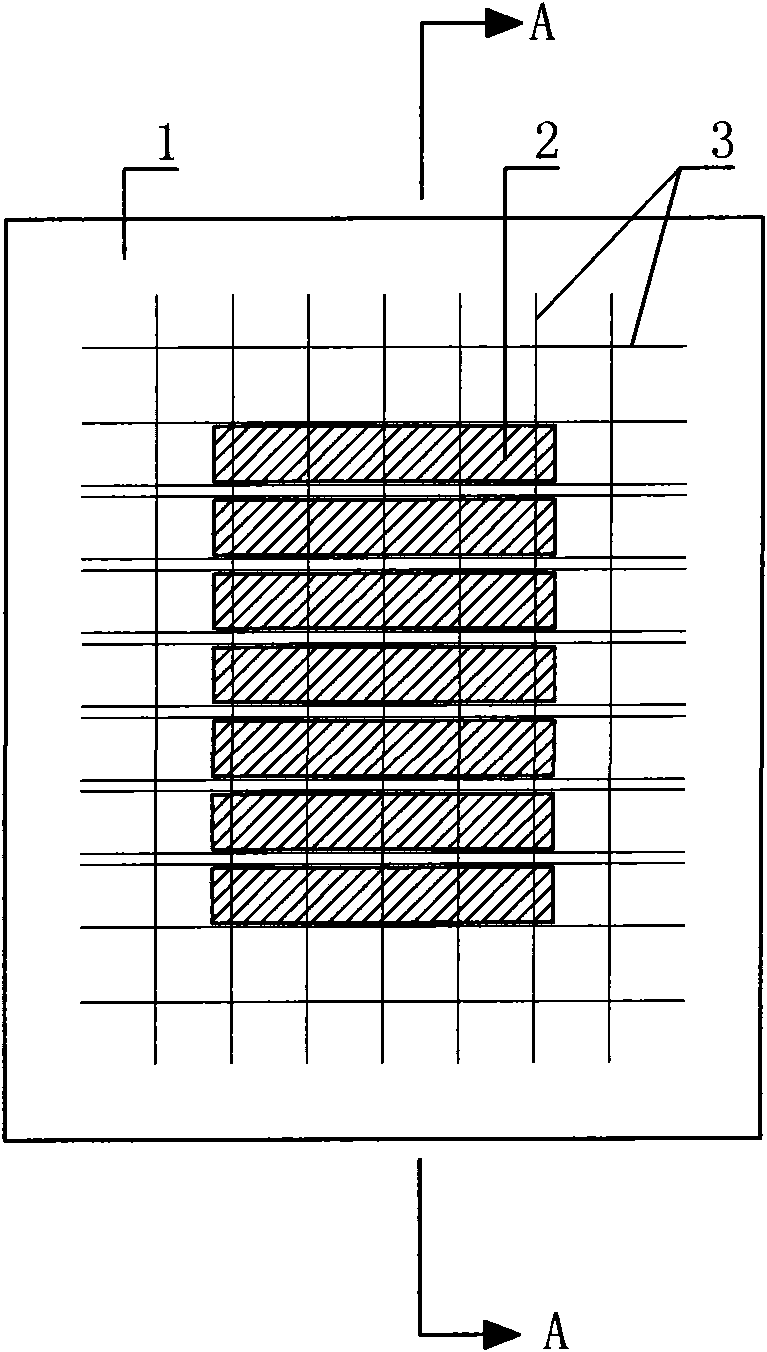

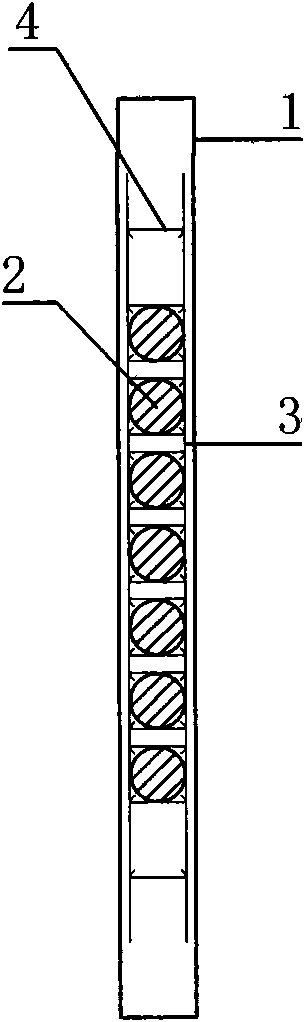

[0014] Concrete shear wall with one-time forming filling wall, its composition includes: concrete shear wall structure prefabricated component 1, said concrete shear wall structure prefabricated component has lightweight filler 2 inside, said lightweight filler is composed of The reinforcement mesh 3 and the tie bars 4 are fixed at the middle part of the prefabricated member of the concrete shear wall structure and arranged regularly according to fixed intervals.

Embodiment 2

[0016] In the above-mentioned concrete shear wall with one-time forming filling wall, the lightweight filler is composed of a thin-walled hollow tube with a certain strength, a foam body or a lightweight porous body, and the two ends of the thin-walled hollow tube are closed, Its cross-sectional shape is circular, or rectangular, or polygonal, etc., and the outer diameter of the lightweight filler is smaller than the thickness of the prefabricated component of the concrete shear wall structure.

Embodiment 3

[0018] In the above-mentioned concrete shear wall with one-shot filling wall, the steel mesh sheet is welded horizontally and vertically by steel bars at fixed intervals, and extends around.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com