Gas blowby prevention method used for circulating fluid bed garbage furnace, and external type overheating device

A waste incinerator and circulating fluidized bed technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve problems such as corrosion of the heating surface of serpentine tubes, and achieve the effect of avoiding metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

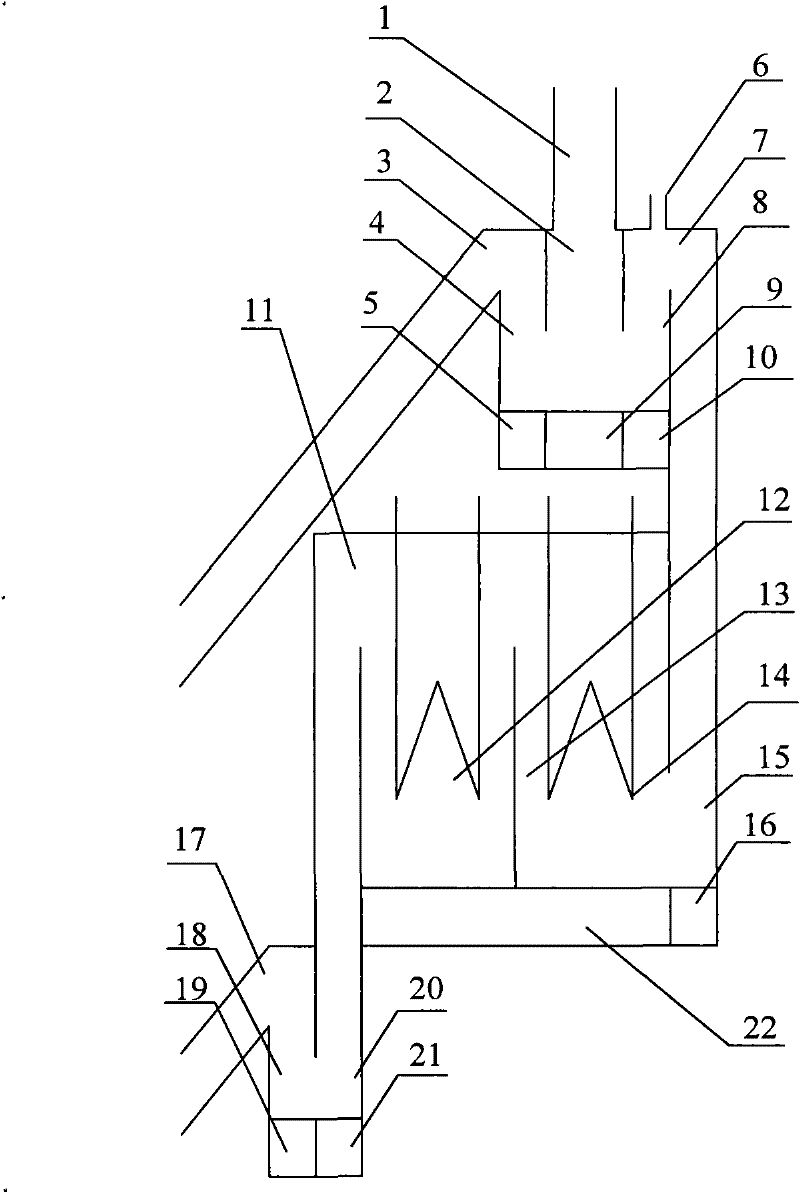

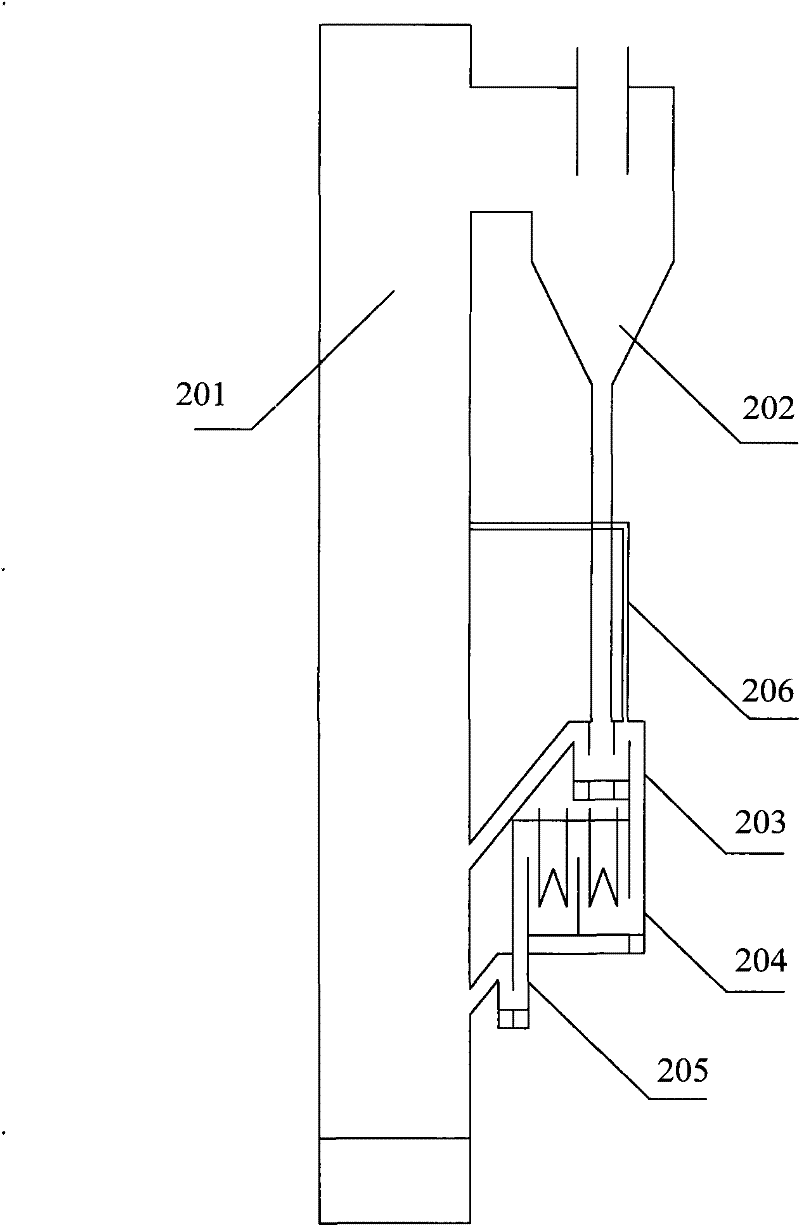

[0023] In order to make the above objects, features and advantages of the present invention more concise and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The core idea of the present invention is: in the circuit where the external superheater communicates with the hearth of the circulating fluidized bed waste incinerator, a return device for realizing material sealing is provided to effectively prevent the flue gas containing HCL and other acid gases from flowing into the hearth. Gas blow-by in the external superheater greatly reduces the metal corrosion of the external superheater and improves the service life of the external superheater.

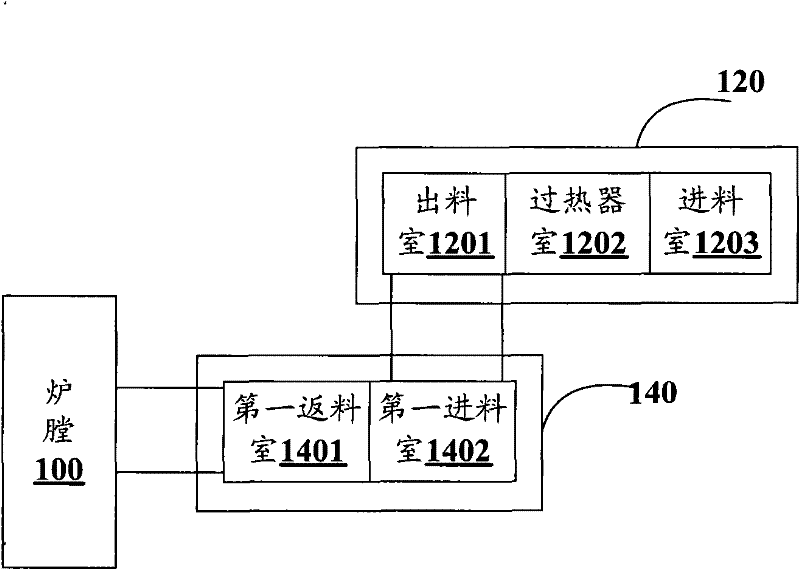

[0025] refer to figure 1 , figure 1 It is a schematic structural diagram of an embodiment of an external superheating device of the present invention. The external superheating device includes: a superheater chamber 120 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com