Monocular vision measuring method of non-contact precision measuring corner

A monocular vision and measurement method technology, applied in measurement devices, special data processing applications, instruments, etc., can solve the problems of increased measurement errors, inconvenient use, and difficulty in accurately knowing the center distance of camera pixels, achieving simple adjustment. , The effect of flexible installation position

Inactive Publication Date: 2010-08-25

ZHONGBEI UNIV

View PDF2 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the structure of the three-circle mark is relatively complicated and loose, and the intersection point of two intersecting straight line segments must be used to accurately mark the center position of each circle, which makes digital image processing difficult and takes a long time; due to the use of "three points to determine a plane" method Finding the plane equation of the target surface, this method is not strong in anti-interference ability, and the measurement accuracy is not high enough; especially, when the angle between the normal line of the target surface and the main optical axis of the camera is close to 0°, the measurement error will increase significantly; This method must also know the center distance of the camera pixels, so that the required results can be obtained during data processing

In the absence of a special digital camera for photogrammetry, it is generally difficult to accurately know the center distance of the camera pixels when measuring with an ordinary digital camera, and the internal parameters of the camera must be obtained through complex and precise calibration, which is not convenient enough to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

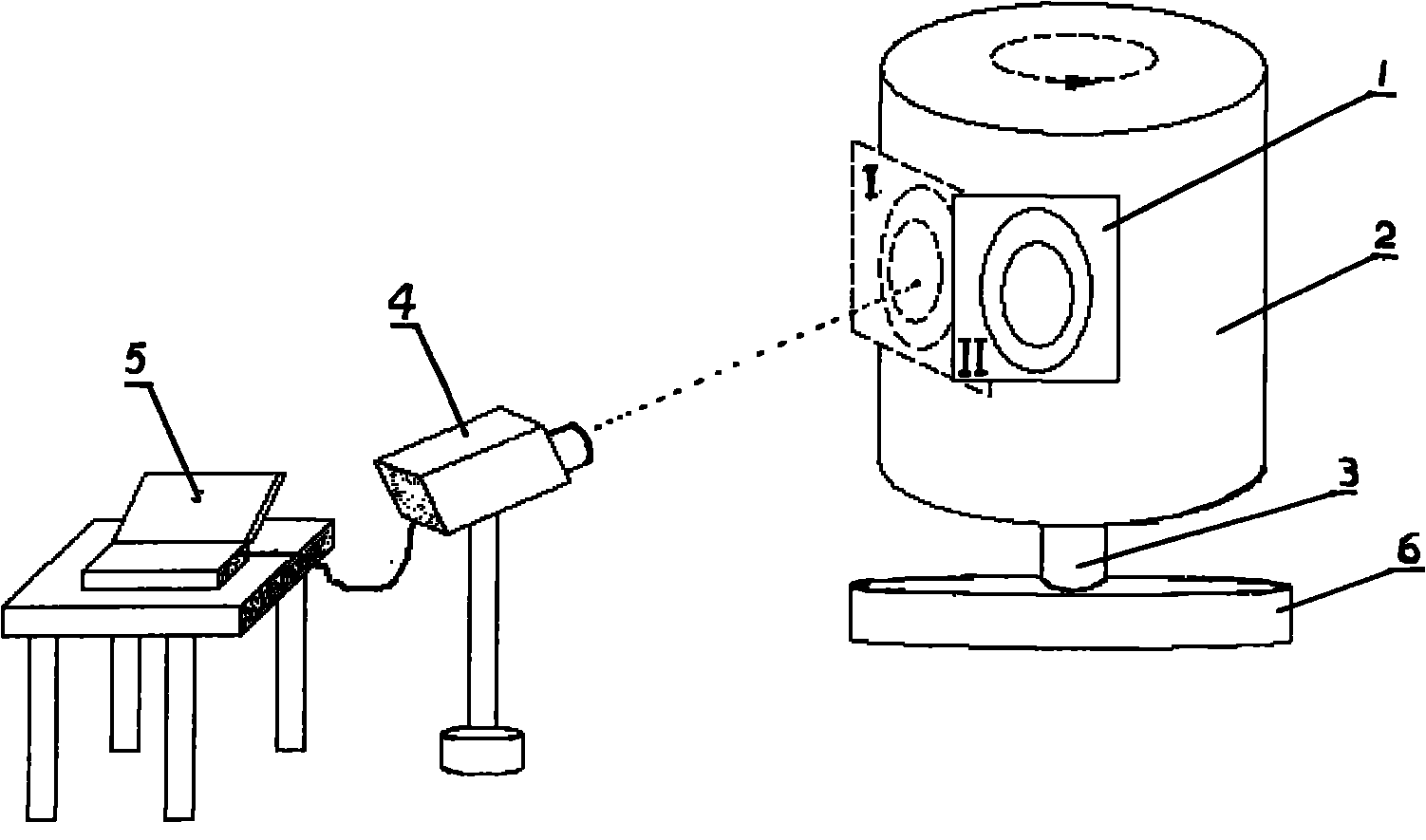

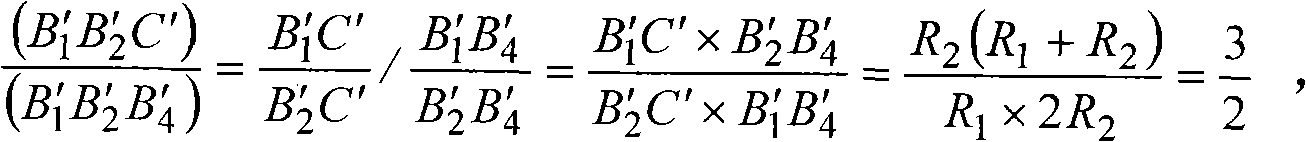

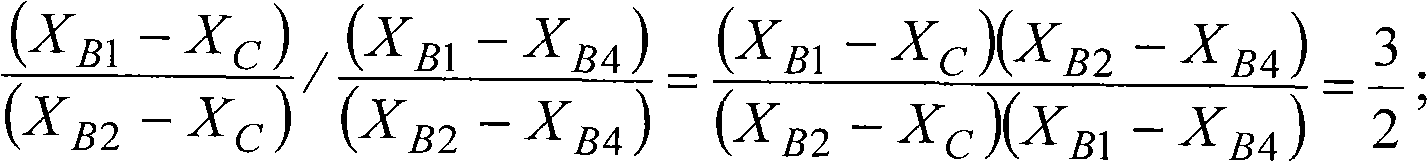

The invention discloses a monocular vision measuring method of a non-contact precision measuring corner, belonging to the technical field of photoelectric detection and aiming at realizing wider measuring range, high measuring precision and more convenient operation. Based on a monocular vision principle, the method comprises the following steps of: fixing a test target with a double-circle sign on an object to be measured parallel to a rotating shaft; photographing a target surface by using a position-fixed digital camera; selecting a group of characteristic points and characteristic parameters of an image surface to establish a set of computing method and formula for solving the corner by taking an image of the double-circle sign as an oval; processing photos by using a sub-pixel processing method, solving an equation of an image surface oval and image surface coordinates of the characteristic points and solving a plane equation of the target surface and a corner of the object to be measured; accurately solving the position of an image point in the center of a circle without marking the position of the center of a circle of the target surface; and correcting a measuring error caused by unparallel relations of the target surface and the rotating shaft by using data obtained in the measuring process. The invention has the advantages of simple installation and adjustment of equipment, high measuring precision, high practicability and capability of being used for marking angular displacement transducers such as a rudder, a horizontal rudder of an aircraft and the like on site of an airport.

Description

Monocular vision measurement method for non-contact precision measurement of rotation angle technical field The invention relates to a monocular vision measurement method for non-contact precise measurement of rotation angle, belonging to the technical field of photoelectric detection. Background technique In the fields of aviation, aerospace and navigation, it is often necessary to use methods and technologies for non-contact precision measurement of rotation angles with a large measurement range. For example, when developing a new type of aircraft or producing an aircraft, after the aircraft is manufactured, a test flight is required to test its flight performance. In order to obtain accurate performance test data, before the test flight, it is necessary to calibrate the angular displacement sensors of the ailerons, flaps, horizontal rudders and rudders on the aircraft at the airport. Because it is not allowed to make any changes to the internal structure of the aircraf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B11/26G06F19/00

Inventor 何森张晓明于慧李慧生高永全曹美珍何迪和

Owner ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com