Tetrahedral ultrasonic wind sensor and measuring method thereof

A tetrahedral, ultrasonic wind technology, applied in the direction of fluid velocity measurement, measurement device, velocity/acceleration/shock measurement, etc., can solve the problems of invalid measurement results, unusable, increase the difficulty of calculation, etc., to simplify the sensor structure, reduce Cost and failure rate, effect of good surface divergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

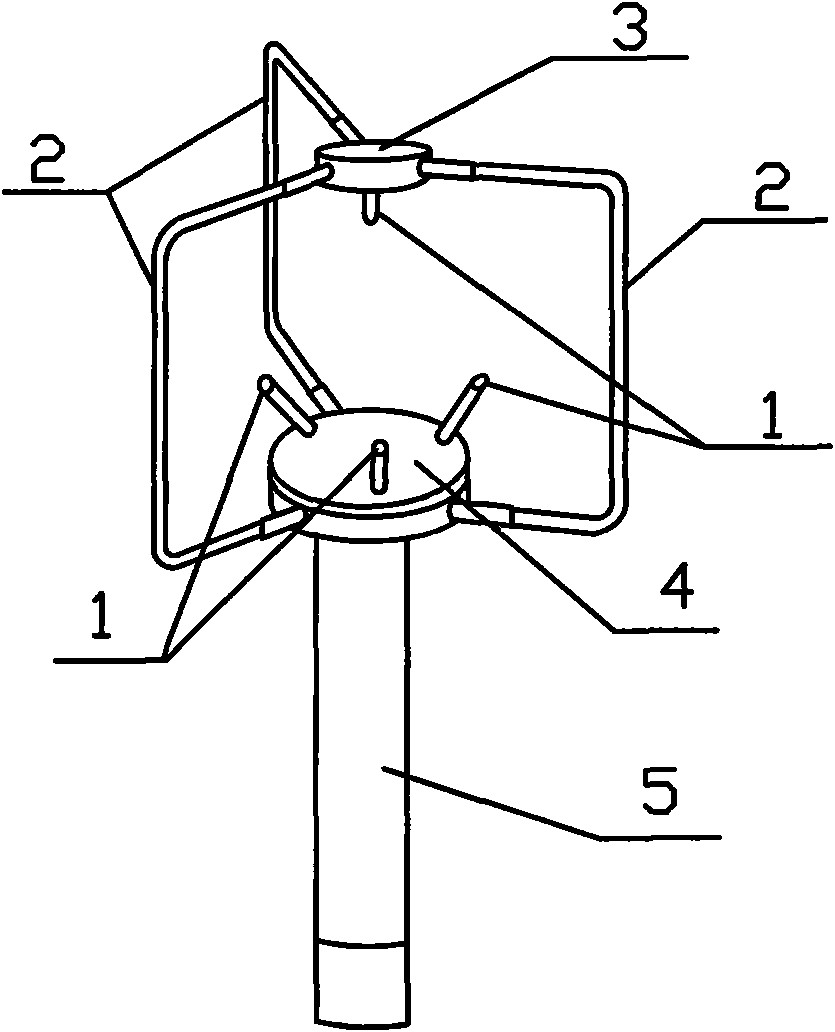

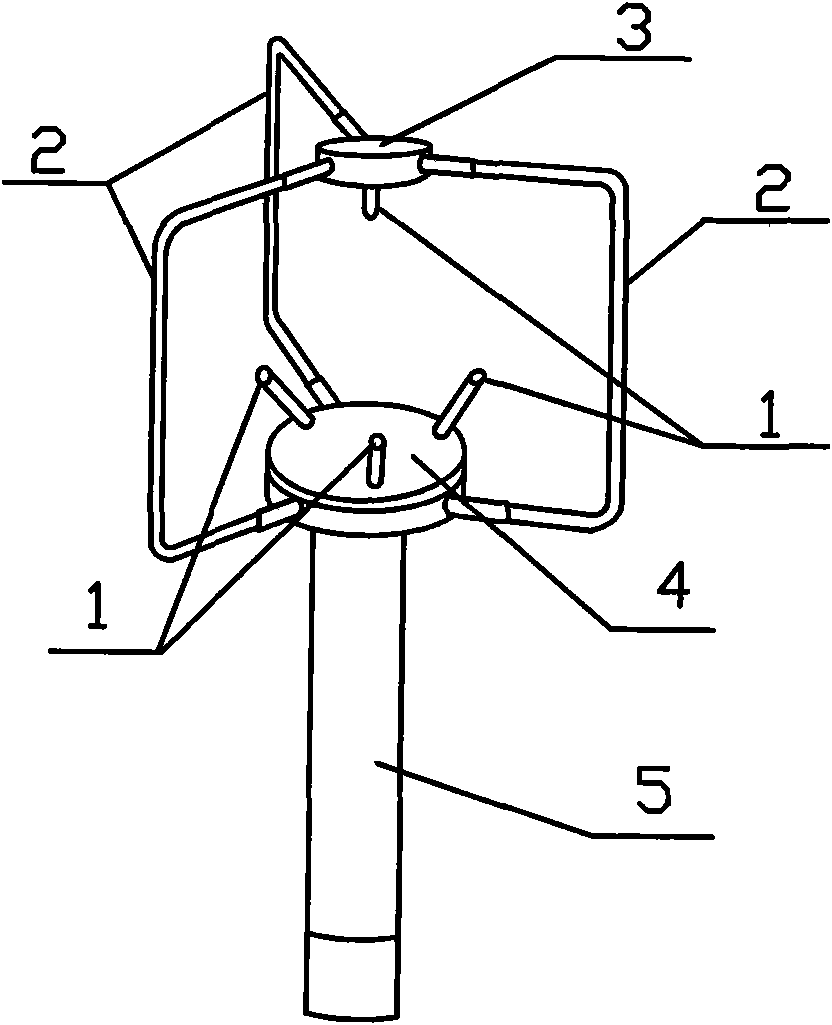

[0029] Embodiment 1 takes the regular tetrahedron as an example

[0030] The four ultrasonic probes 1 are arranged at the vertices of the regular tetrahedron, that is, the tetrahedron 8 defined by the center point 7 of the bottom surface of the scattering cover 6 of the four ultrasonic probes 1 is a regular tetrahedron. A regular tetrahedron means that the four sides of the tetrahedron are regular triangles, the six sides are equal, and the angles between all vertices are 60 degrees. As shown in Figure 4, keep a side level, take it as the XY-plane, take a vertex in the plane as the origin O, take a horizontal path starting from the origin O as the X axis, and establish standard coordinates according to the method described in the present invention Tie. The regular tetrahedron has good spatial symmetry, and the included angles of its paths are equal, so when calculating the two-dimensional wind speed, three-dimensional wind speed, and X, Y, Z three-axis wind speed components i...

Embodiment 2

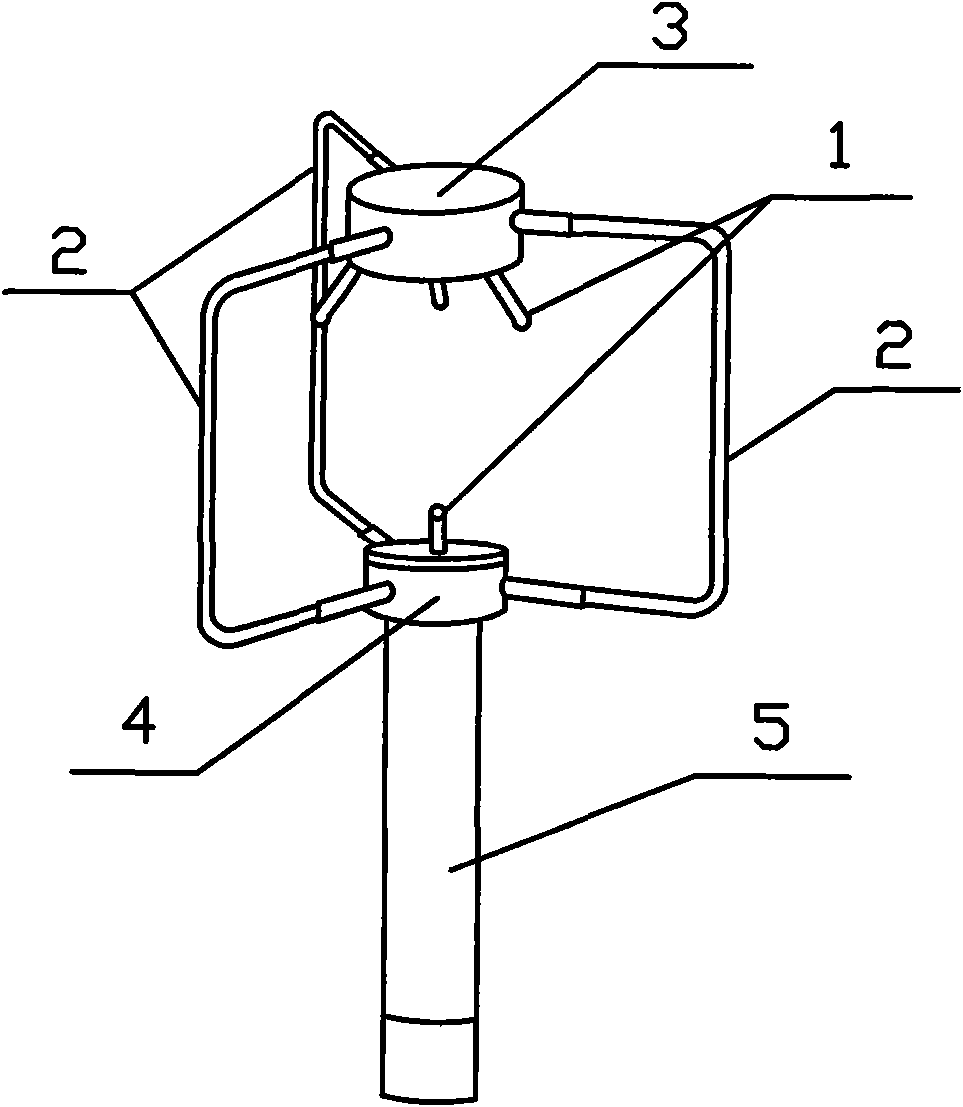

[0031] Embodiment 2 takes the right-angled tetrahedron as an example

[0032] The four ultrasonic probes 1 are arranged at the vertices of the right-angled tetrahedron, that is, the tetrahedron 8 determined by the center point 7 of the bottom surface of the scattering cover 6 of the four ultrasonic probes 1 is a right-angled tetrahedron. A right-angled tetrahedron is a tetrahedron with a right-angled vertex, and three right-angled sides containing the right-angled vertex are perpendicular to each other. Therefore, take a right-angled side as the XY-plane, take the right-angled vertex as the origin O, take a right-angled side starting from the origin O as the X-axis, and the other two right-angled sides as the Y-axis and Z-axis to establish a standard coordinate system. As shown in Figure 4, the three measurement paths a, b, and c starting from the origin coincide exactly with the X, Y, and Z axes of the standard coordinate system. According to the measurement method of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com