Tool for live replacement of 220kV line 'V' string insulator and method

A live replacement and insulator technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of troublesome operation procedures, complicated operations, and angle deviation, and achieve the effect of improving operation efficiency, reducing labor intensity and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

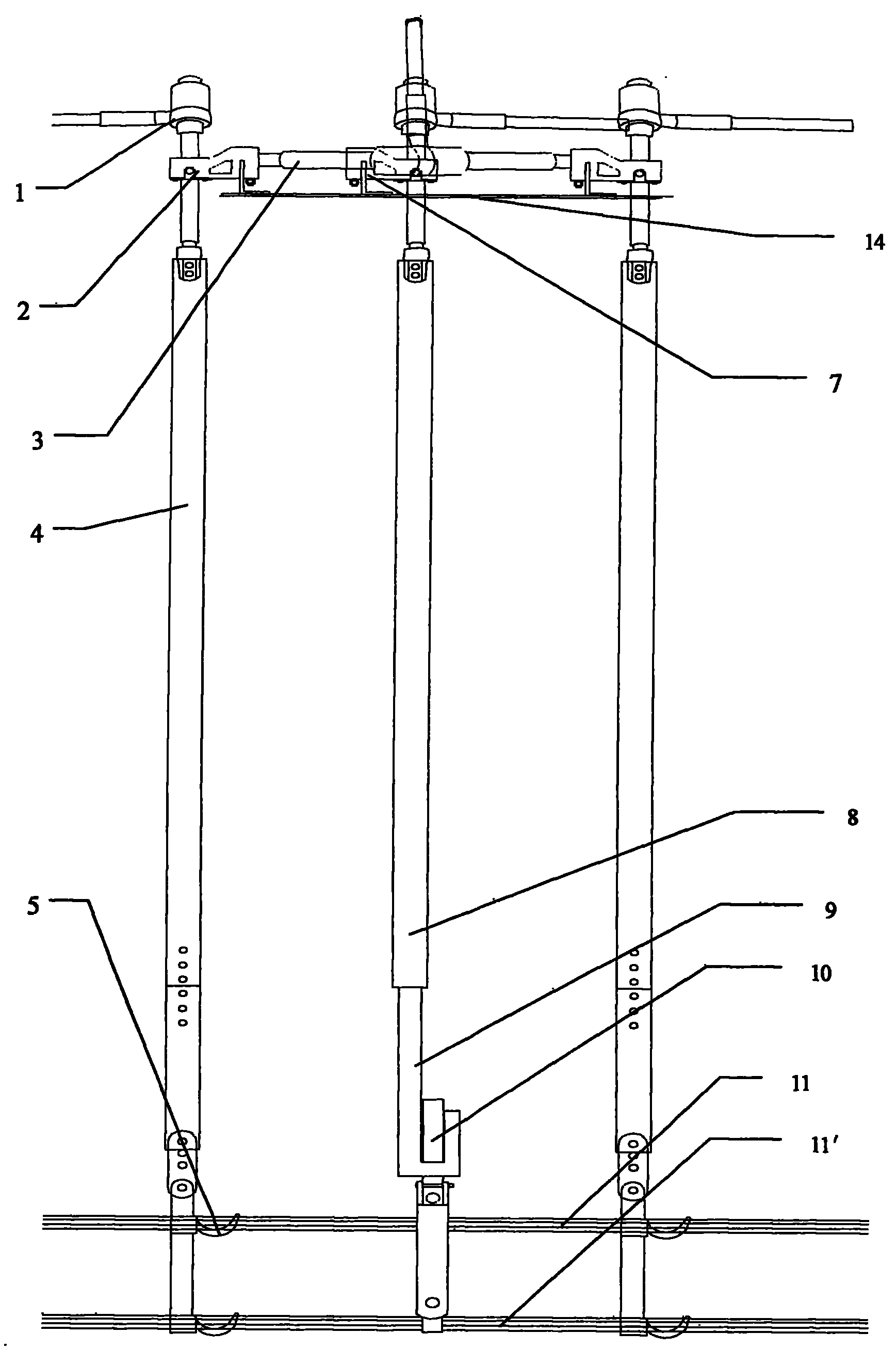

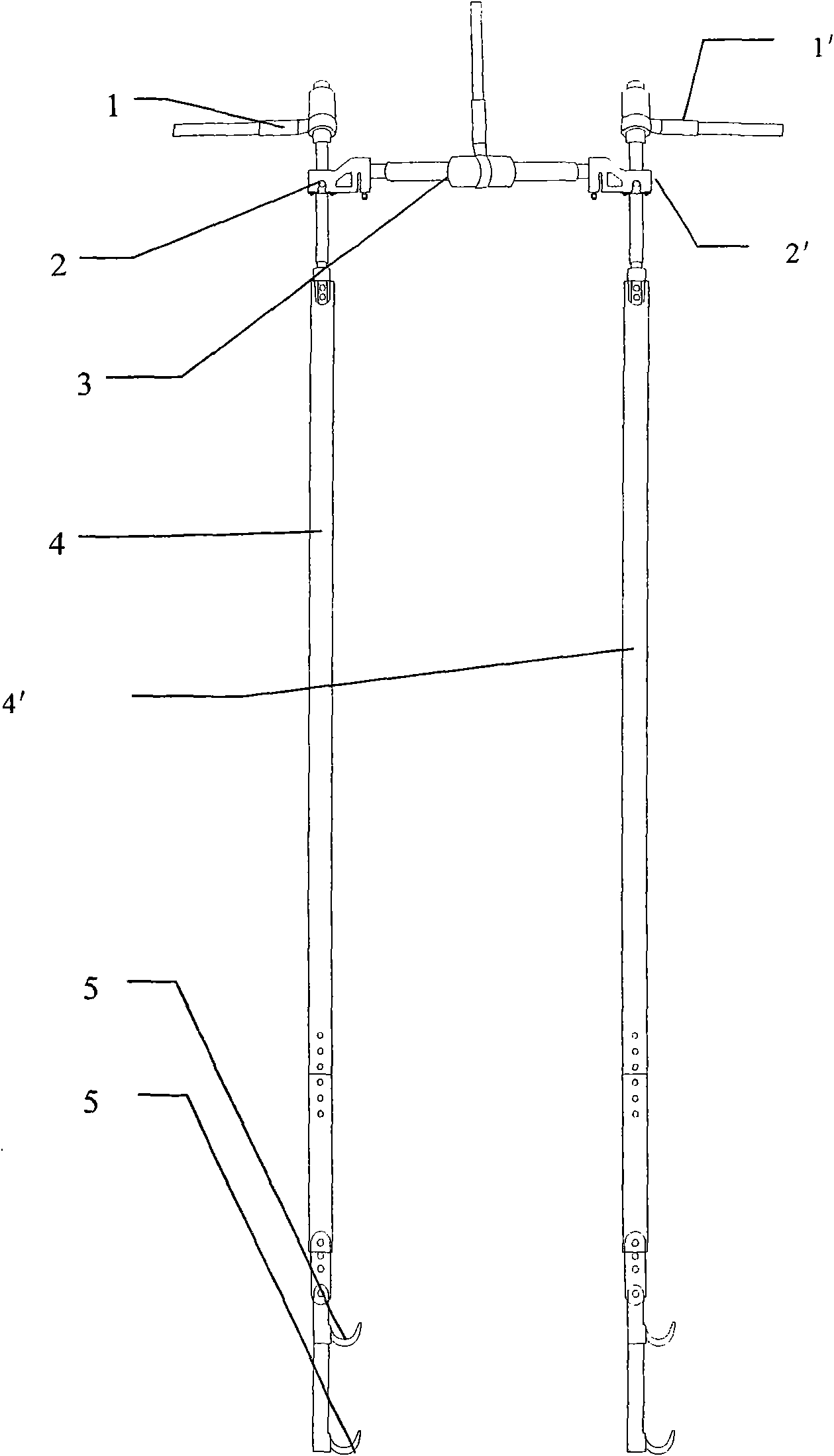

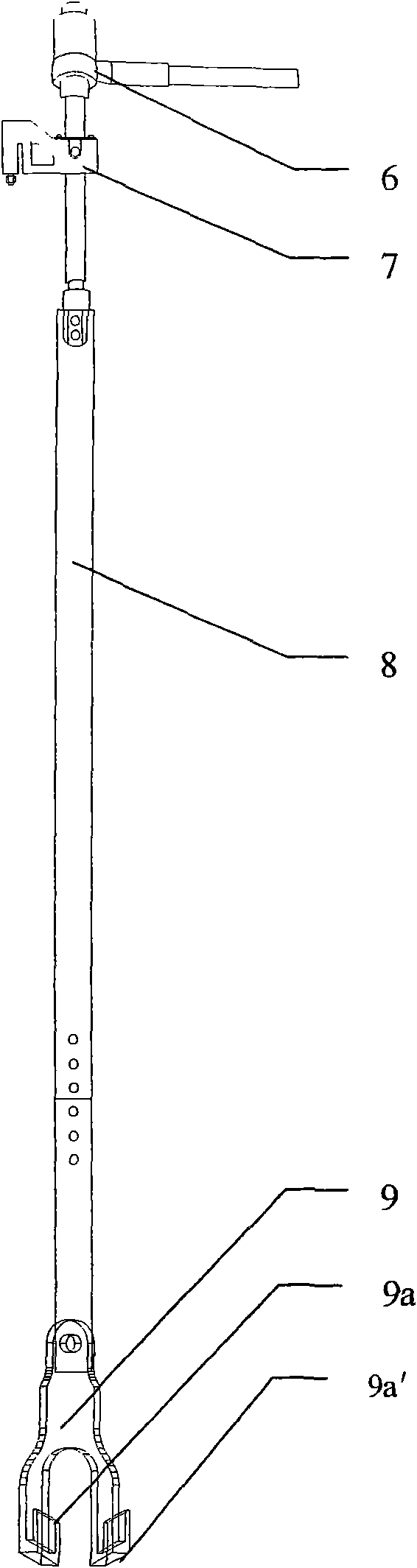

[0020] The tool of the present invention includes a load-bearing component and a V-shaped connecting plate component used in conjunction. As shown in Figure 1, the load-bearing member includes the same two longitudinal first insulating pull plates 4, 4', first tightening screw rods 1, 1' and The double-split hanging wire hooks 5, 5' connected to the bottom of the first insulating pull plate are equipped with the first angle steel clamps 2, 2' symmetrically on the two first tightening screw rods 1, 1' respectively. A horizontal double-ended screw mandrel 3 with both ends being screw mandrels is connected between the first angle steel fixtures. As shown in Figure 2, the V-shaped connecting plate member includes a longitudinal second insulating pull plate 8, a second tightening screw 6 longitudinally connected to the top of the second insulating pull plate, and a second tightening screw rod 6 connected to the bottom end of the second insulating pull plate. The V-shaped connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com