Gearbox torque testing system

A testing system and gearbox technology, applied in torque measurement, measurement device, power measurement, etc., can solve the problems of smaller power angle adjustment range, uncontrollable rotor excitation angle, larger lag excitation angle, etc., to save equipment. Cost, convenient equipment maintenance, good control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention controls the rotor excitation current of the winding motor (doubly-fed motor) to adjust the phase angle and strength of the rotor excitation, and then controls the torque of the motor to realize the torque test of the gearbox.

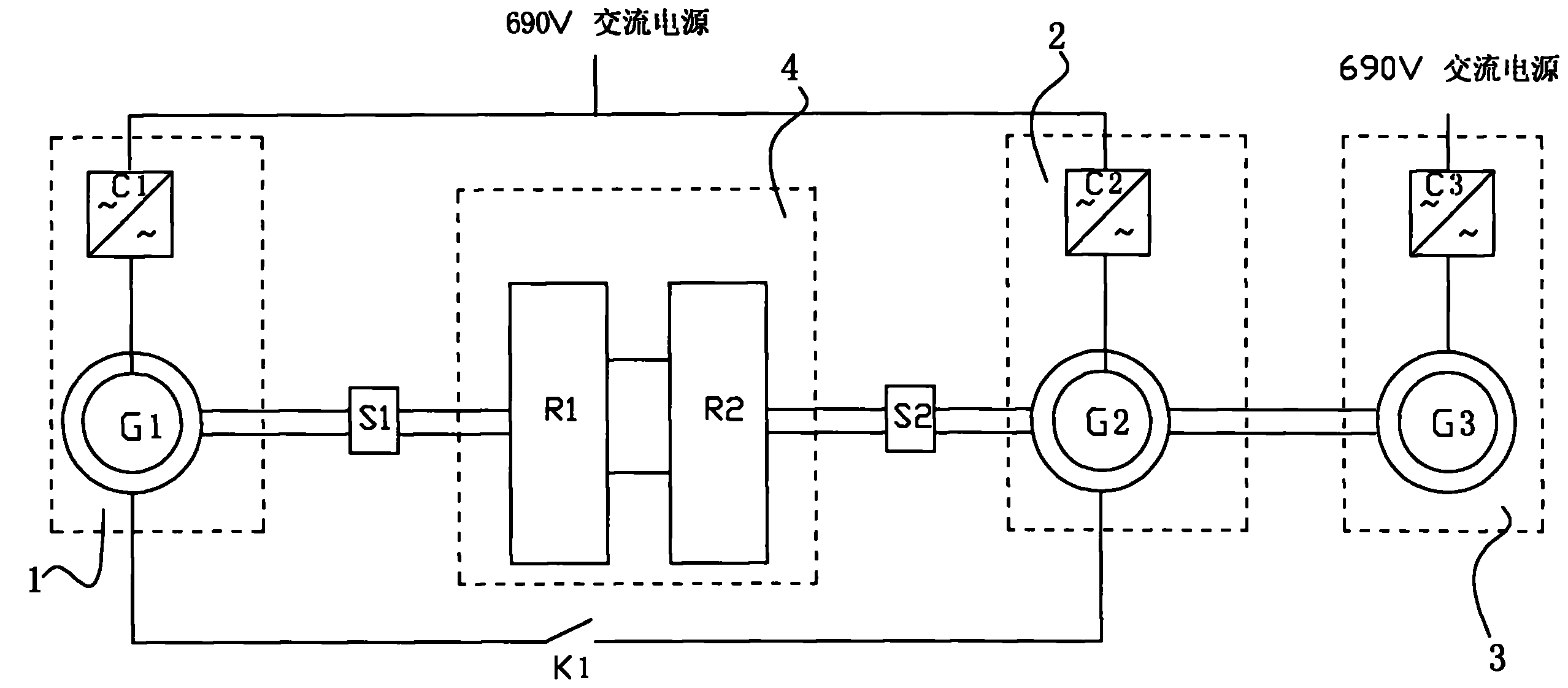

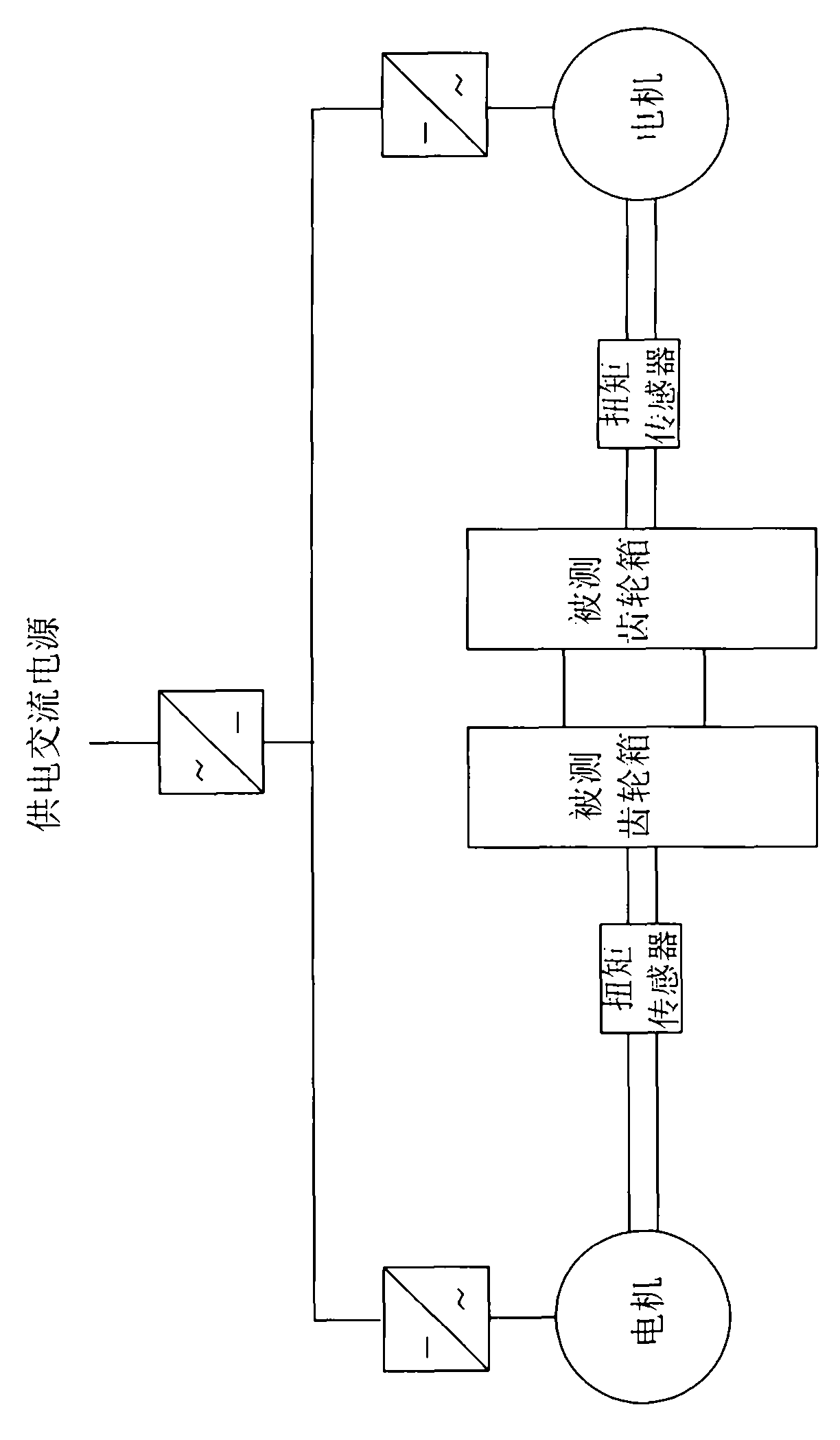

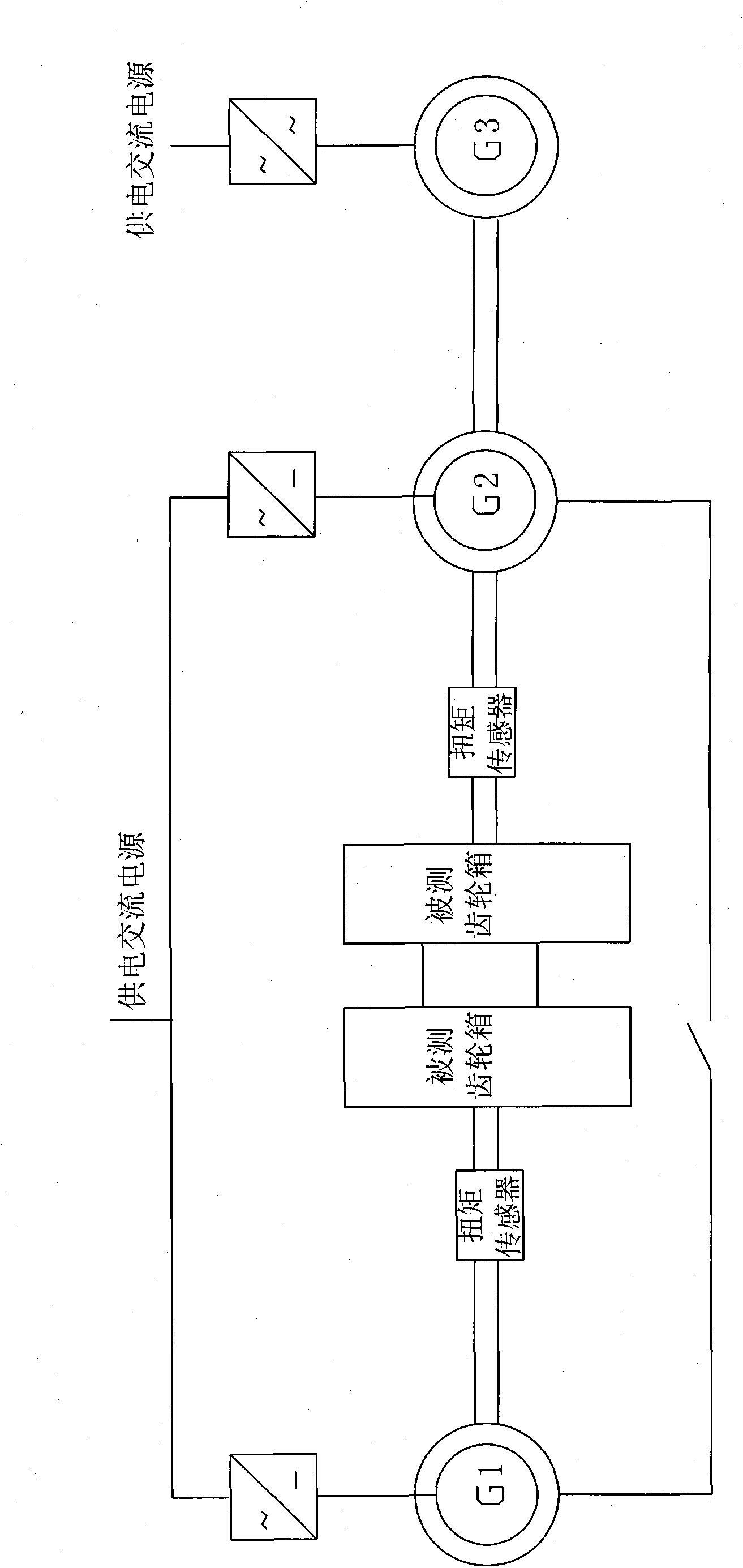

[0019] As shown in FIG. 3 , in the gearbox torque testing system, the tested gearbox R1 and the tested gearbox R2 are two tested gearboxes with the same speed ratio. The low-speed ends of the tested gearbox R1 and the tested gearbox R2 are rigidly connected through the flange, and the high-speed ends are respectively connected to the motor G1 and the motor G2; the torque sensor S1 and the torque sensor S2 are torque sensors, which can detect the tested gearbox R1 and the torque generated on the high-speed shaft of the measured gearbox R2; interconnect the stator power supply wiring of the motor G1 and the motor G2, and the frequency converter C3 is the frequency converter that controls the prime mover G3, mainly to provide compensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com