Security laminates with interlaminated transparent embossed polymer hologram

A technology of holograms and polymer films, applied in the properties/properties of holograms, holographic processes, layered products, etc., can solve problems such as unsuitable for tamper-proof interlayer lamination and difficult duplication of laminated materials

Inactive Publication Date: 2010-08-25

AGFA GEVAERT AG

View PDF13 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Second, desirable laminates are difficult, if not impossible, to replicate by counterfeiters

Commercially available transparent molded holograms coated with inorganic HRI materials are not suitable for tamper-resistant interlayer lamination in composite systems making up composite ID documents

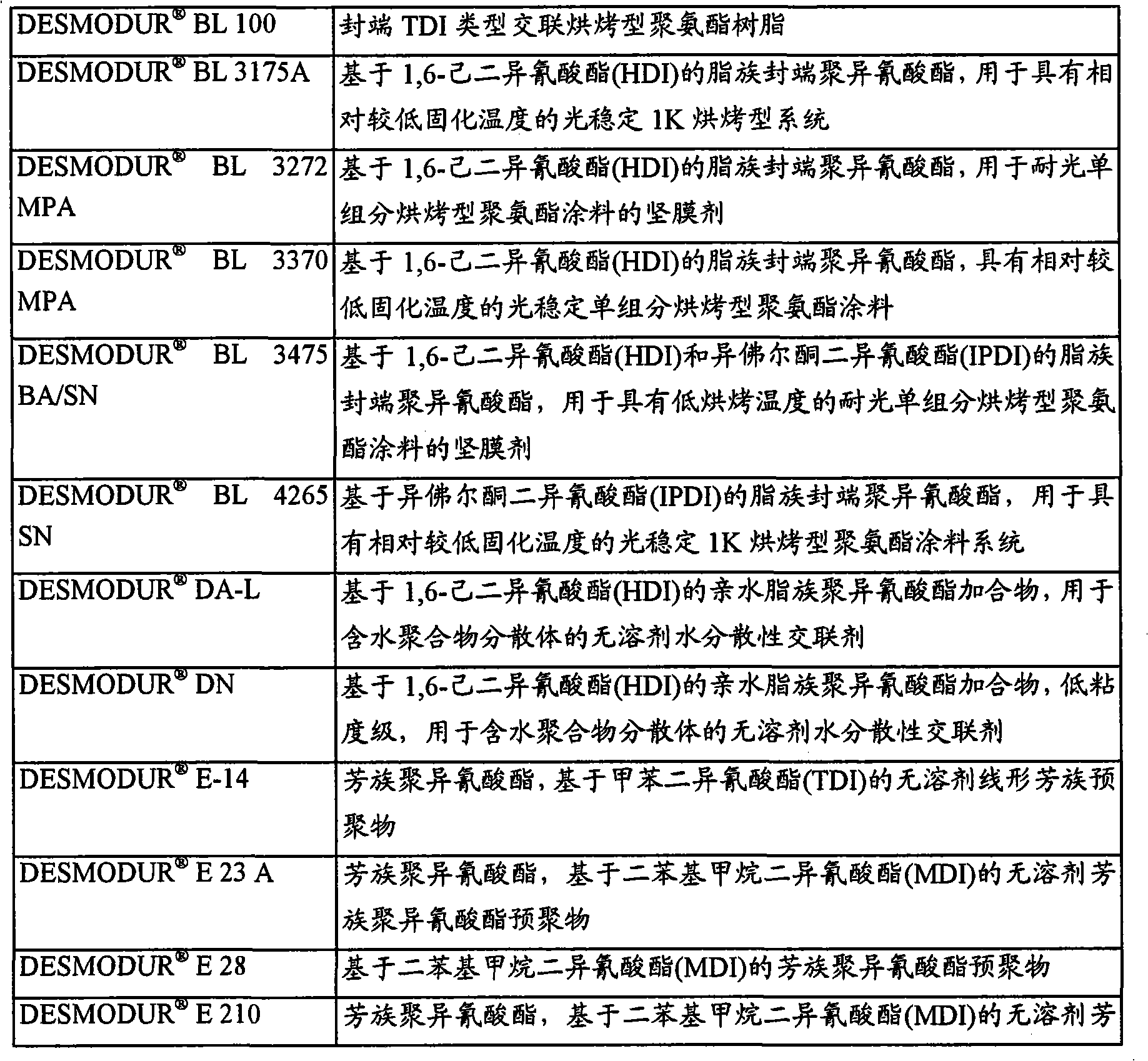

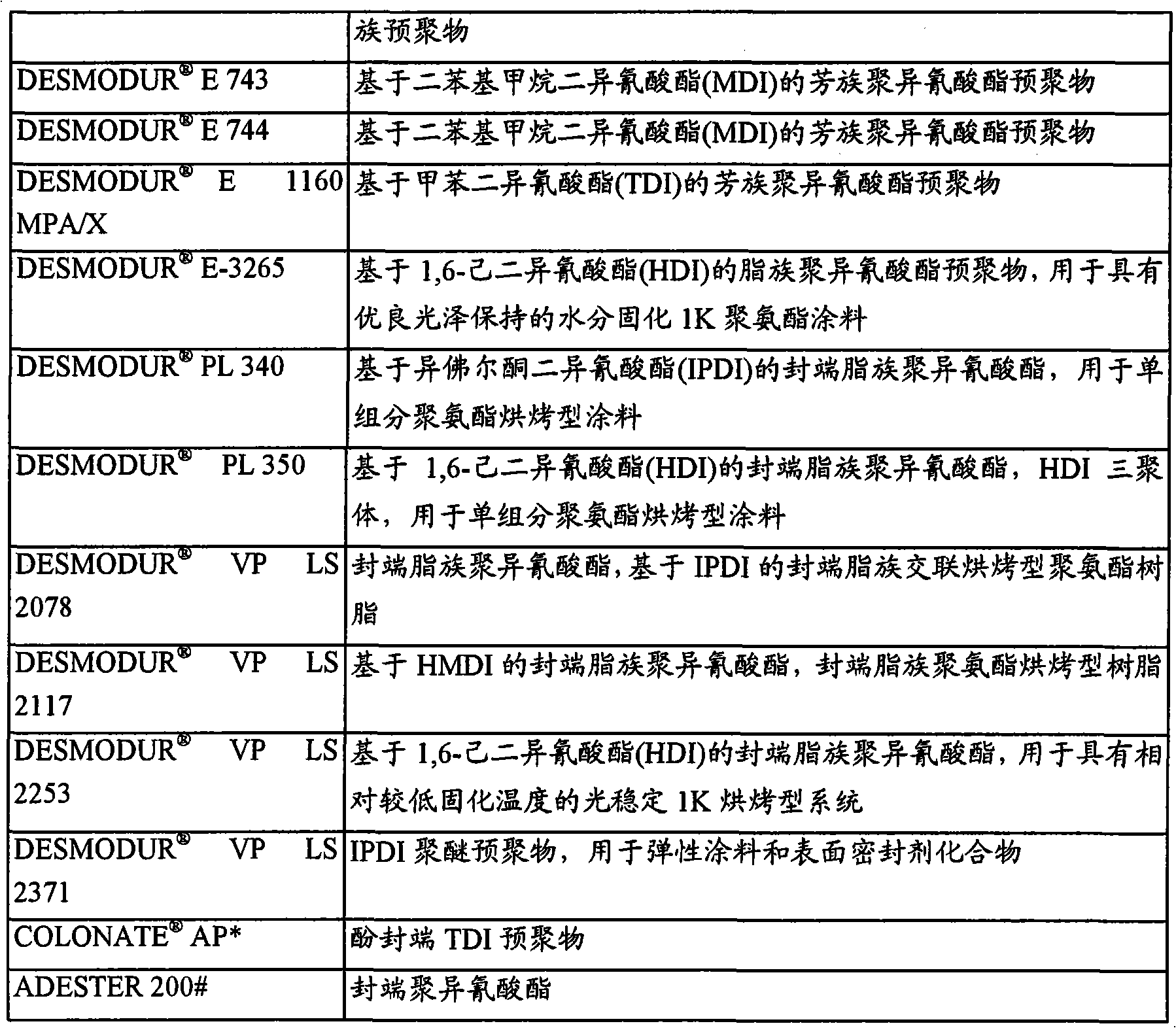

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

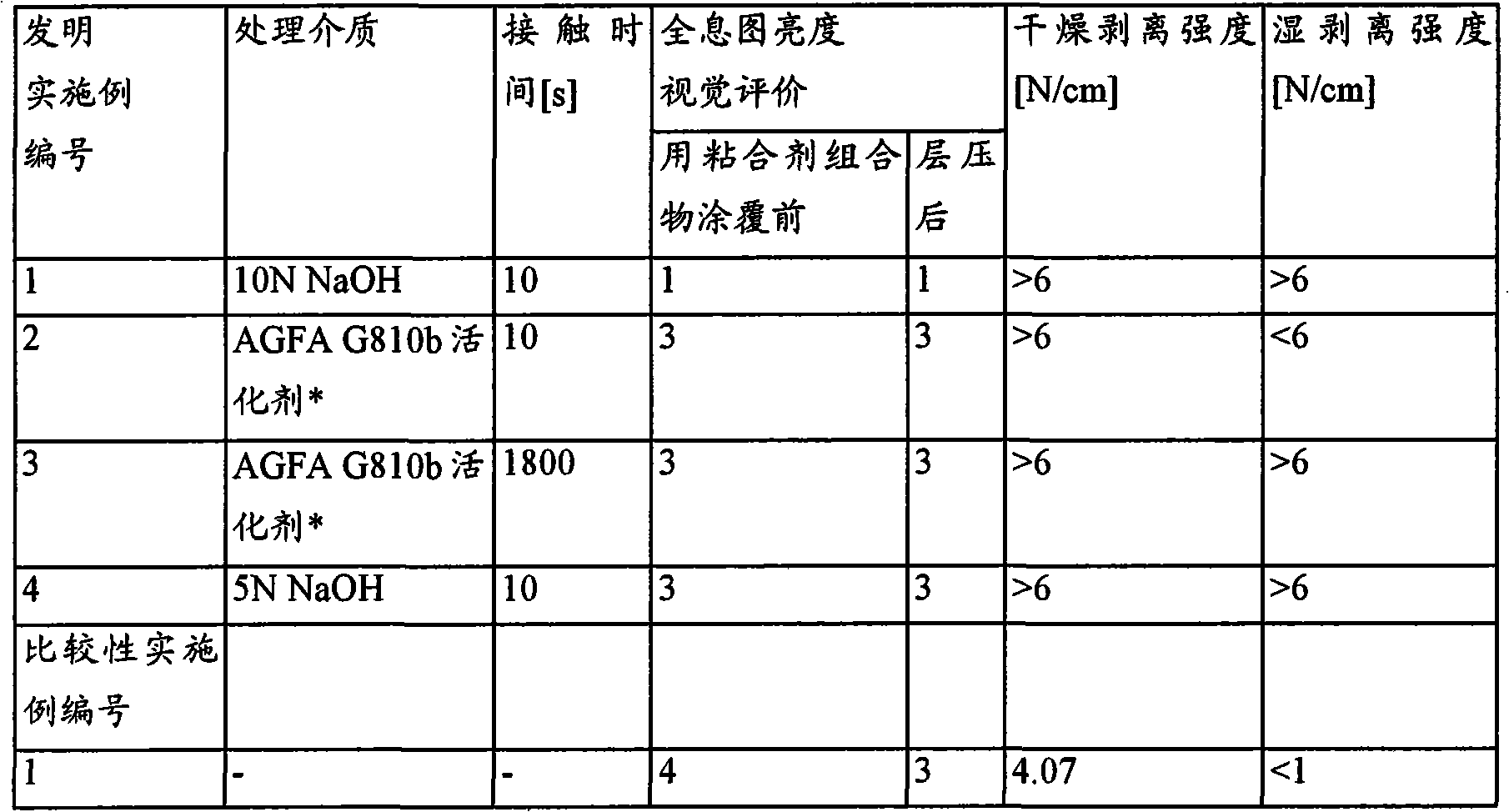

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

A method for interlaminating an embossed hologram, the embossed hologram comprising an optionally transparent support having two sides, at least one of the two sides either itself being embossed or having a layer thereon which is embossed and a layer of a HRI- material contiguous with the embossed side or embossed layer, comprising the steps of : a) conditioning the outermost surface of the layer of inorganic HRI- material with an alkaline solution or an acidic solution; b) drying the outermost surface of the layer of the inorganic HRI- material thereby providing a conditioned outermost surface of the layer of inorganic HRI-material; c) applying a layer of an adhesive composition to the conditioned outermost surface of the layer of inorganic HRI-material support; and d) laminating the outermost surface of the layer of HRI-material to a polymer film, wherein at least one of the support and the polymer film is transparent; and wherein the HRI material is a material with a refractive index of at least 0.3 higher than that of the embossed material. A laminate obtainable therewith, and a security document comprising the laminate are also disclosed.

Description

Field of Invention The present invention relates to a security laminate with an interlayer laminated transparent molded polymer hologram comprising a coating of an inorganic HRI material and a process for obtaining said material. Background of the Invention Security laminates are traditionally used to protect documents or packaging to secure underlying items from alteration by including an authenticating feature, making them difficult to counterfeit. Security laminates are used in particular on identity documents such as driver's licenses, ID cards and passports, but also on other important documents such as title deeds. Security laminates are also used as tamper-evident seals on pharmaceuticals, videotapes, and compact discs. There are 5 characteristics that are particularly important when making and using security laminates. First, once applied to the article, the laminate is difficult to remove, so it is important to ensure that the underlying item is not altered or tam...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B3/30B32B27/14B42D15/10G09F3/02G03H1/02C09J5/02

CPCG03H2250/35G03H1/0244G03H2250/36C09J5/02B42D25/328B32B7/12G03H1/02B42D2035/22C09J2400/123G03H1/0256G03H2240/50G03H2240/54B32B27/08G03H1/028G03H1/0011B32B2307/5825Y10T156/10

Inventor I·格恩斯

Owner AGFA GEVAERT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com