Magnetic core and use of magnetic core for electrical machines

A technology of magnetic core and magnetic permeability, applied in the field of manufacturing magnetic core and electrical steel sheet, can solve the problem of decreased energy efficiency of motor, and achieve the effect of reducing energy dissipation, improving efficiency and ensuring magnetic flux

Inactive Publication Date: 2010-08-25

THYSSEN KRUPP STAHL AG

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The energy efficiency of the motor will decrease overall as the energy dissipation due to losses increases

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

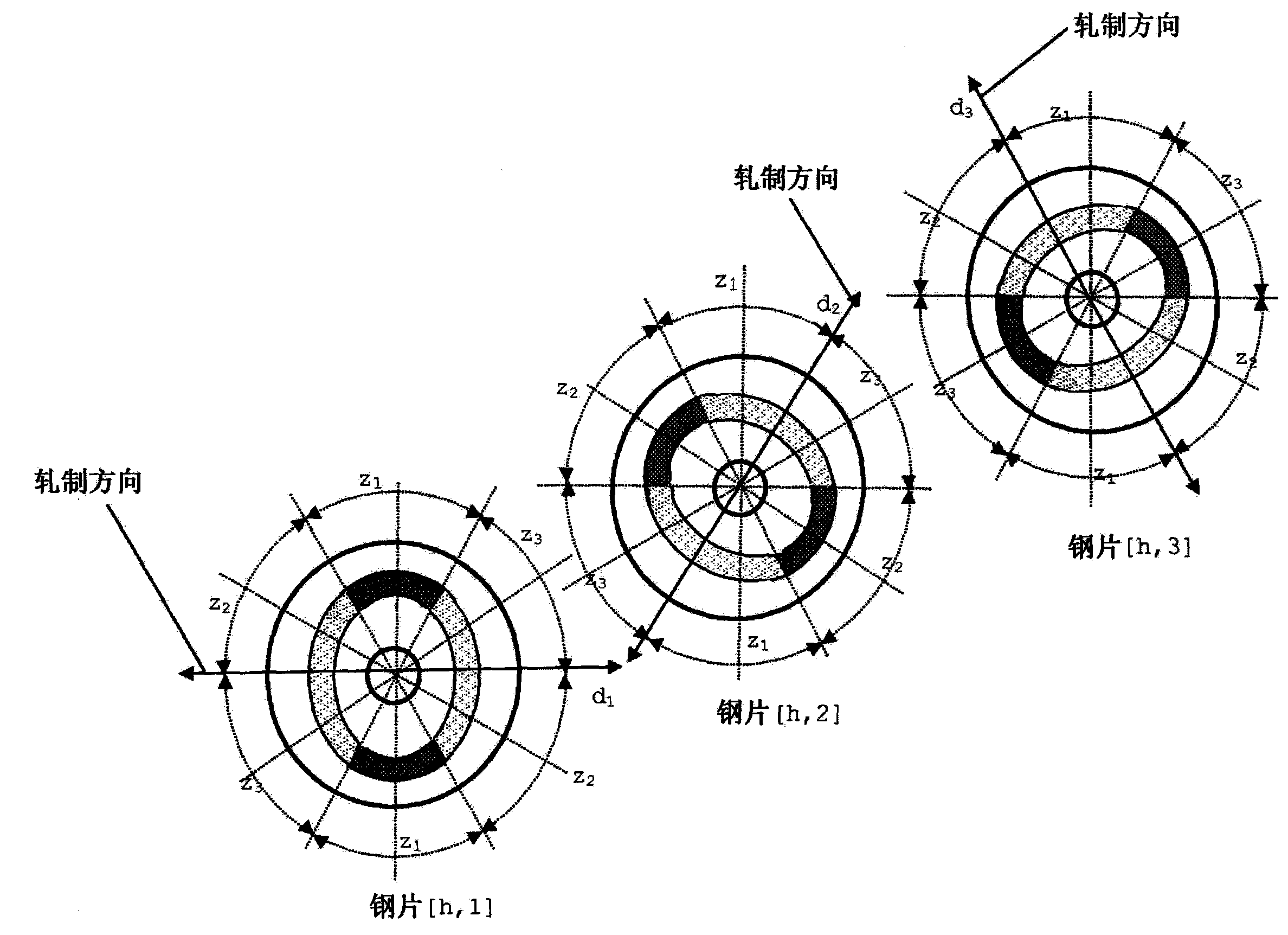

A magnetic core is described comprising a stack of electrical steel sheets with a known preferential direction of permeability. In the stack the preferential direction of permeability of successive single sheets and in addition or alternatively of successive groups of sheets differs by a predetermined shift angle. Further the use of a magnetic core is described.

Description

Magnetic cores and their use in motors technical field The present invention relates to a magnetic core comprising a stack of electrical steel sheets having a known preferred direction of permeability. Also, a technique for manufacturing a magnetic core including a grain-oriented sheet in order to improve energy efficiency of an AC motor whose core is in a variable magnetic field is disclosed. Background technique Various electrical machines generally include a magnetic core (hereinafter "MC") made essentially of electrical steel. Of course, basically the properties of the electrical steel that makes up the core affect the various properties of the motor. In particular, grain oriented electrical steel can be used for the magnetic core. The microstructure of grain-oriented electrical steel (hereinafter referred to as “GO”) shown in Fig. 1(a) shows these grains with their <001> orientation parallel to the rolling direction (hereinafter referred to as “RD”) Aligned,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02K1/06

CPCH02K1/02H02K1/06

Inventor 让·弗朗索瓦·布鲁德尼贝特朗·卡索莱特雷吉斯·勒迈特让-诺埃尔·文森特

Owner THYSSEN KRUPP STAHL AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com