100-stage cleaning laminar flow inoculation under barotropic atmosphere during edible fungus industrial cultivation

A purification layer and edible fungus technology, applied in the fields of application, botany equipment and methods, horticulture, etc., can solve the problems of edible fungus structure hazards, etc., and achieve the effect of less chance of infecting miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

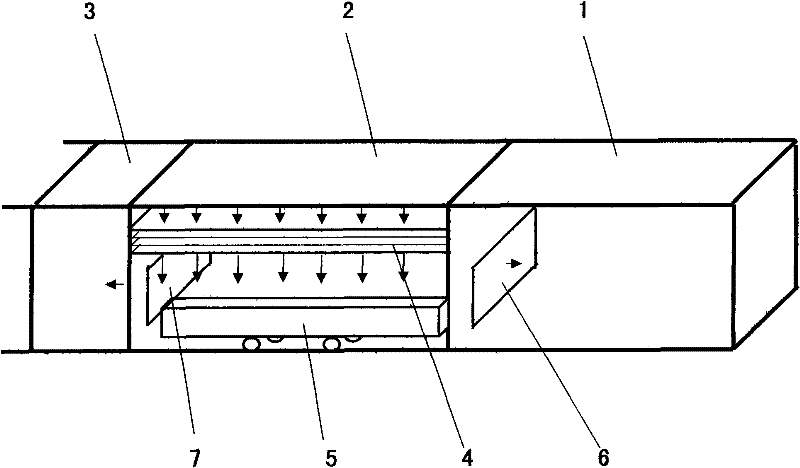

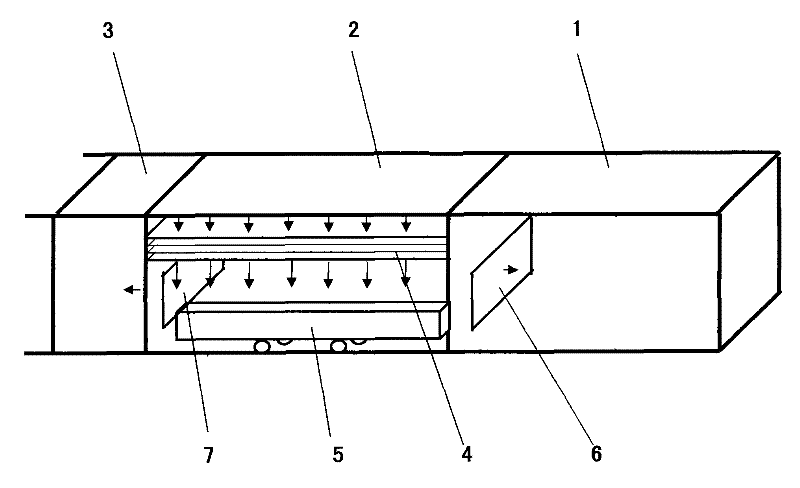

[0018] Below in conjunction with accompanying drawing the implementation details of the present invention are described as follows:

[0019] Such as figure 1 As shown, a positive-pressure 100-level purification laminar flow inoculation method in the industrial cultivation of edible fungi is carried out in an open manner in accordance with the inoculation operating procedures in the inoculation workshop 2 located between the cooling workshop 1 and the aisle 3 of the bacteria cultivation workshop. The area and height of the workshop are compatible with the inoculation amount and inoculation method in industrialized cultivation. There is a transfer window at the entrance to connect with the cooling workshop, and there is a transfer window at the exit to connect with the aisle of the bacteria cultivation workshop. Its characteristics are:

[0020] The air that enters the fresh air treatment room from the outside is treated by medium-efficiency-high-efficiency purification and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com