Shipbuilding method by utilizing floating dock

A floating dock and inner dock technology, which is applied in ship construction, ship parts, ships, etc., can solve the problem that the floating dock cannot provide a reference line, etc., and achieve the effect of improving flexibility, quick effect and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention relates to a method for building a ship using a floating dock, said method comprising the following process steps:

[0028] Step 1. Add a certain amount of ballast water in advance in the ballast tank of the floating dock, and the amount of the ballast water is greater than the total weight of the following total sections.

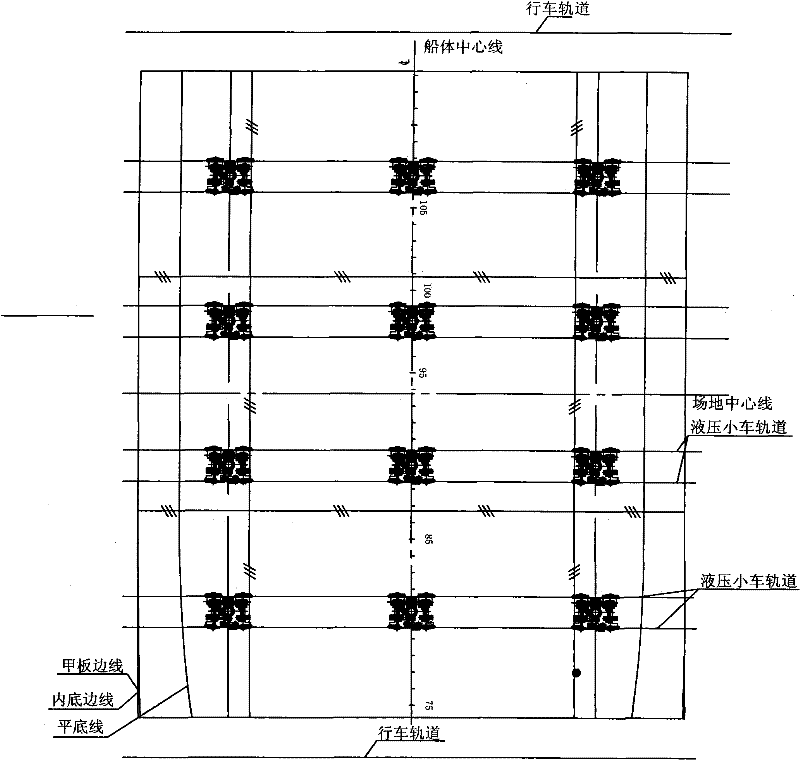

[0029] Step 2. Under the condition of keeping the ballast water volume constant, draw a straight line on the left and right inner dock walls of the floating dock as the deflection control line of the floating dock. The two deflection control lines are 1.4 to 1.6 meters away from the pontoon deck and parallel to each other, and the center line of the new ship is plotted on the pontoon deck of the floating dock as the control line of the new ship center line.

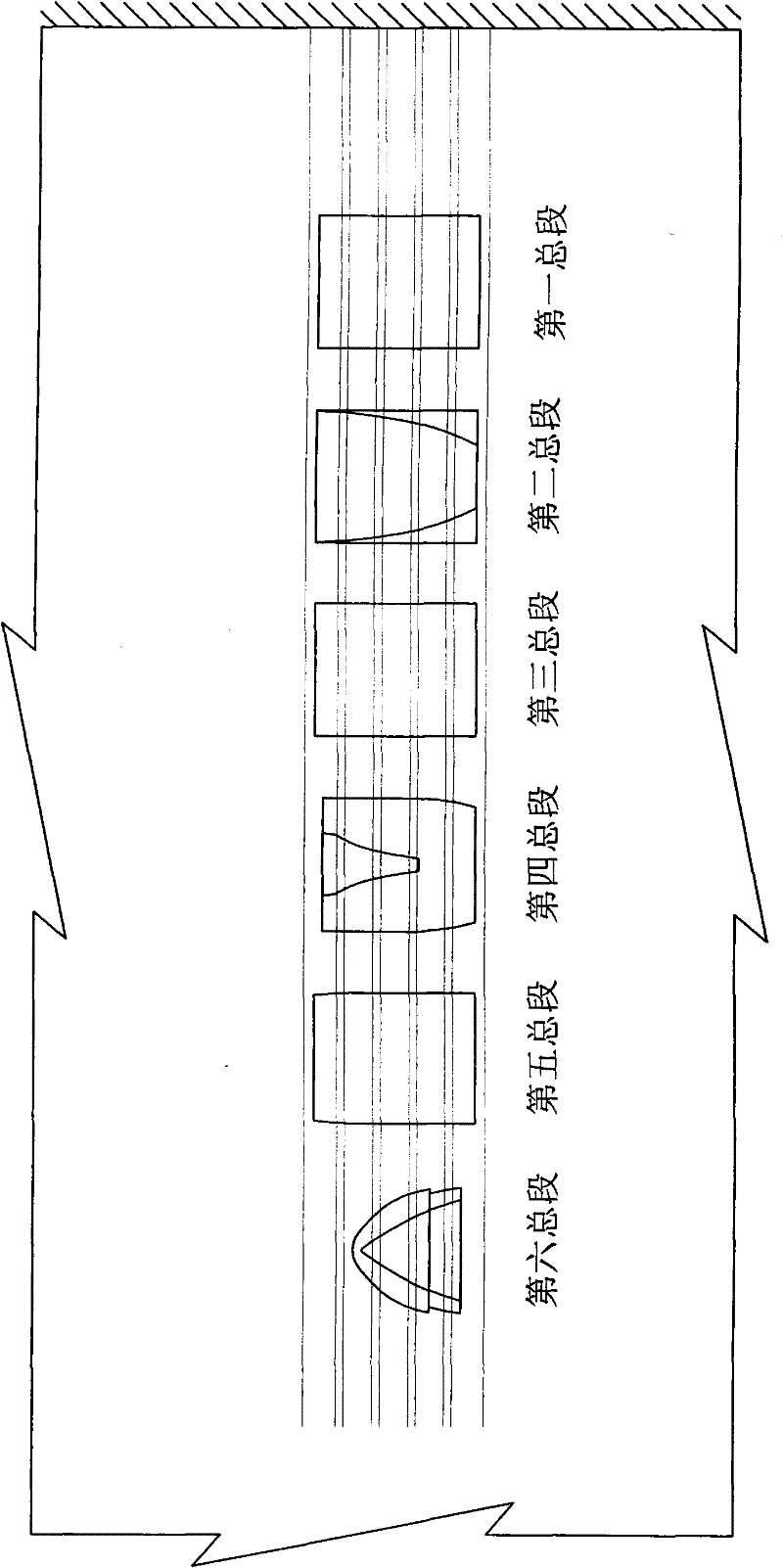

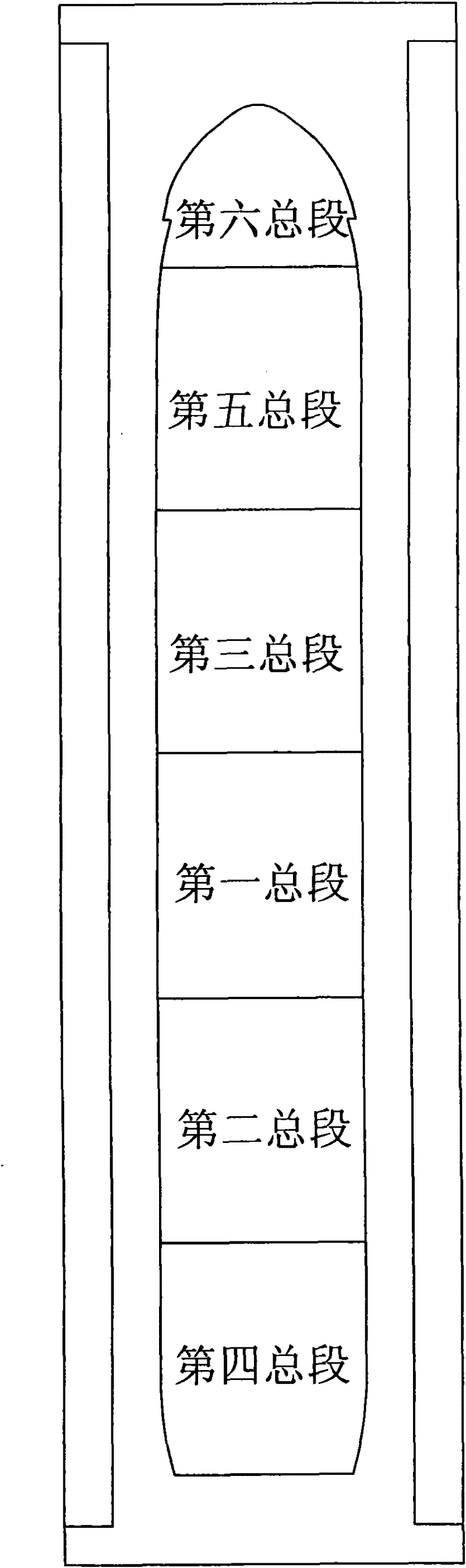

[0030] Step 3. Combine the new ship sections into several general sections on the site of the general group, such as figure 1 . And plot the center line and height posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com