Process for producing sulfamethoxydiazine

A technology for the production of sulfamethoxine, which is applied in the field of veterinary drug sulfamethoxine production technology, and can solve problems such as harsh reaction conditions, numerous production steps, and unmanned production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

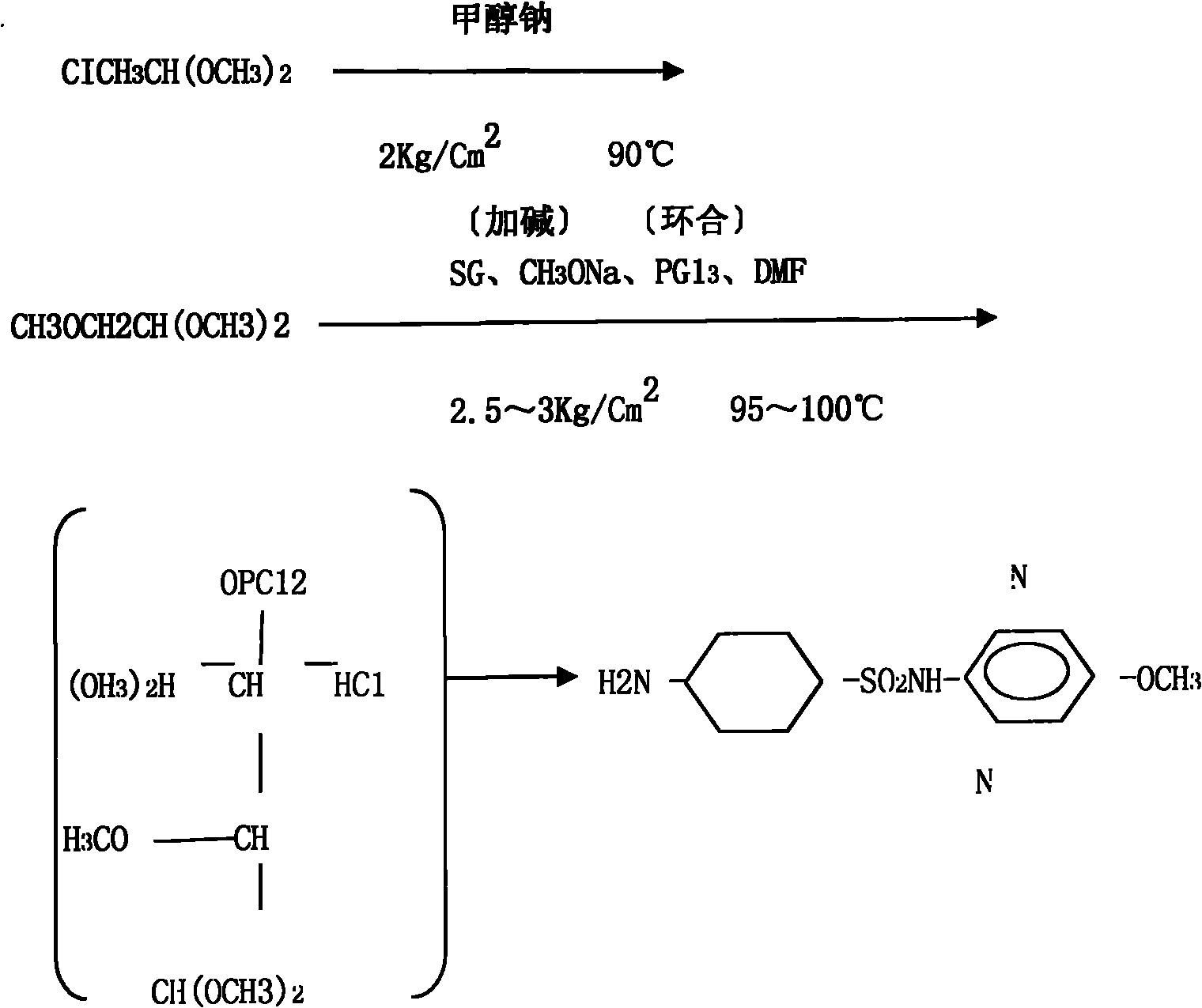

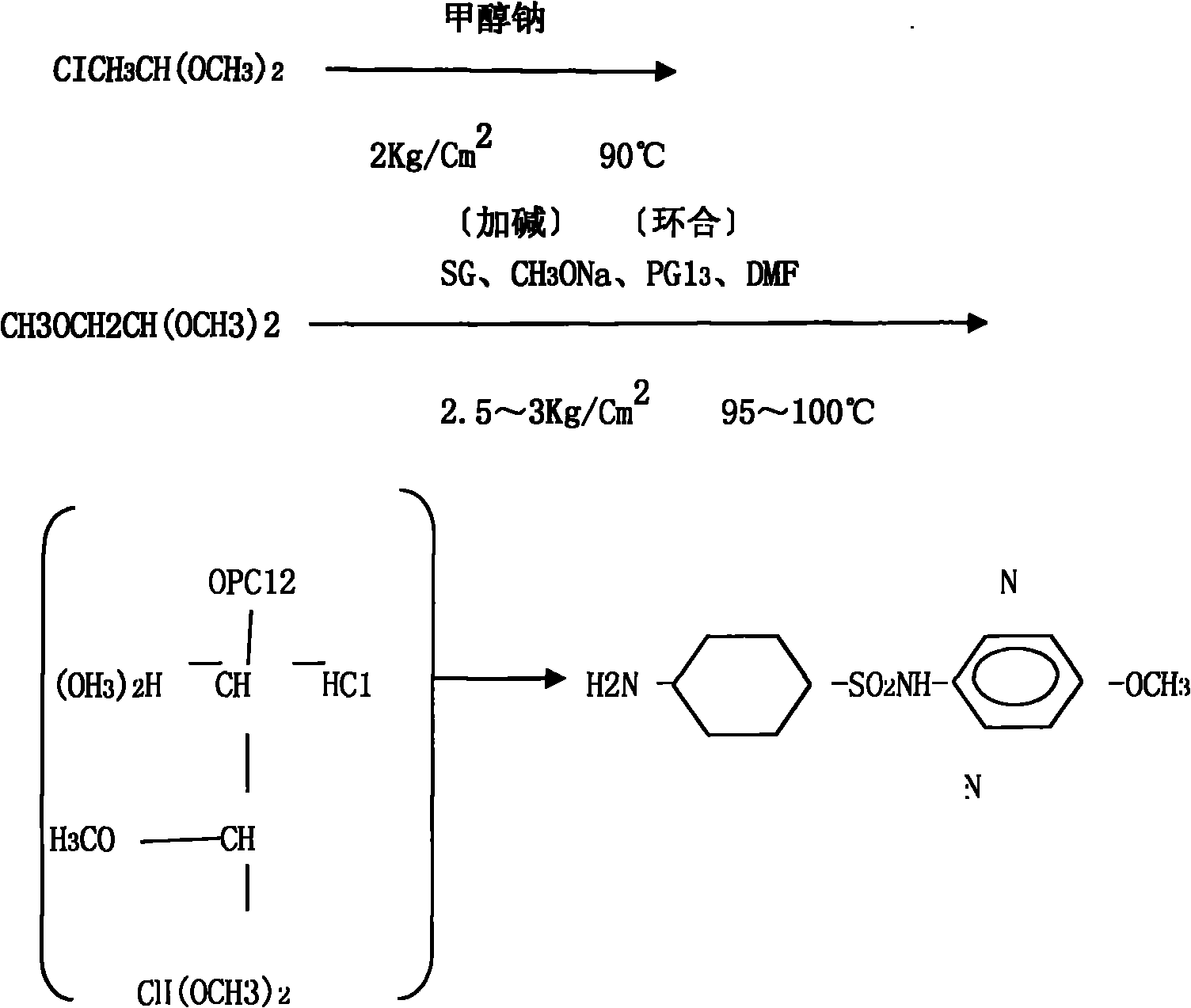

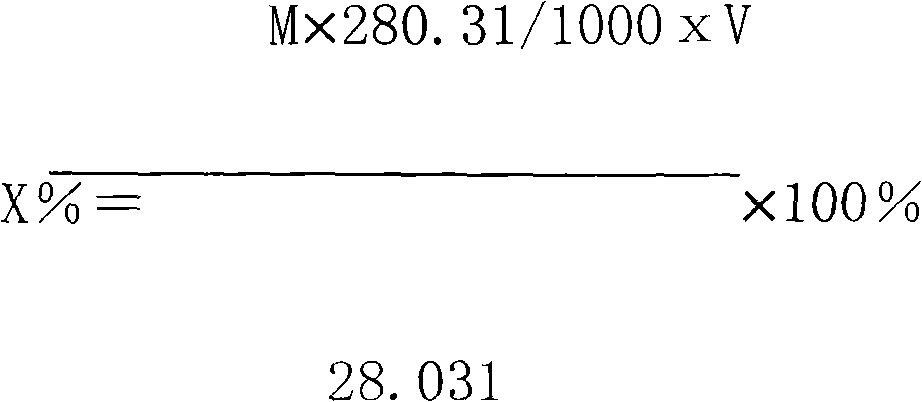

Method used

Image

Examples

Embodiment

[0054] Put 640Kg of sodium methoxide into a 1500I reaction pot, raise the temperature to 64°C, and begin to steam methanol until the material in the pot is solid and basically free of methanol. After the temperature of the material in the pot is cooled to 75°C, slowly add 320Kg of chlorinated fat. After the addition, Heating and reflux, reflux reaction for 2 hours, after the reflux, close all valves, open the steam valve to heat and pressurize the reaction, control the pressure in the pot at 0.3Mpa, pressurize and react for 3 hours, the speed of heating and pressurization should not be too fast, after the reaction is over , when the temperature rises, steam the crude methyl fat. The temperature is above 125°C. Put the steamed crude methyl fat into the rectification pot for rectification. Raise the temperature to 64°C to recover methanol, raise the temperature to 70°C to recover the middle lag, and raise the temperature to 120°C , collect the pure methyl ester and use it as an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com