Method for configuring modules in laboratory of electrolytic aluminum plant

A configuration method and module configuration technology, applied in industrial buildings and other directions, can solve the problems of increasing operating costs, lack of organic coordination of functions, coordination and management confusion, etc., to achieve easy operation and coordination, safe working environment, reasonable and compact layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

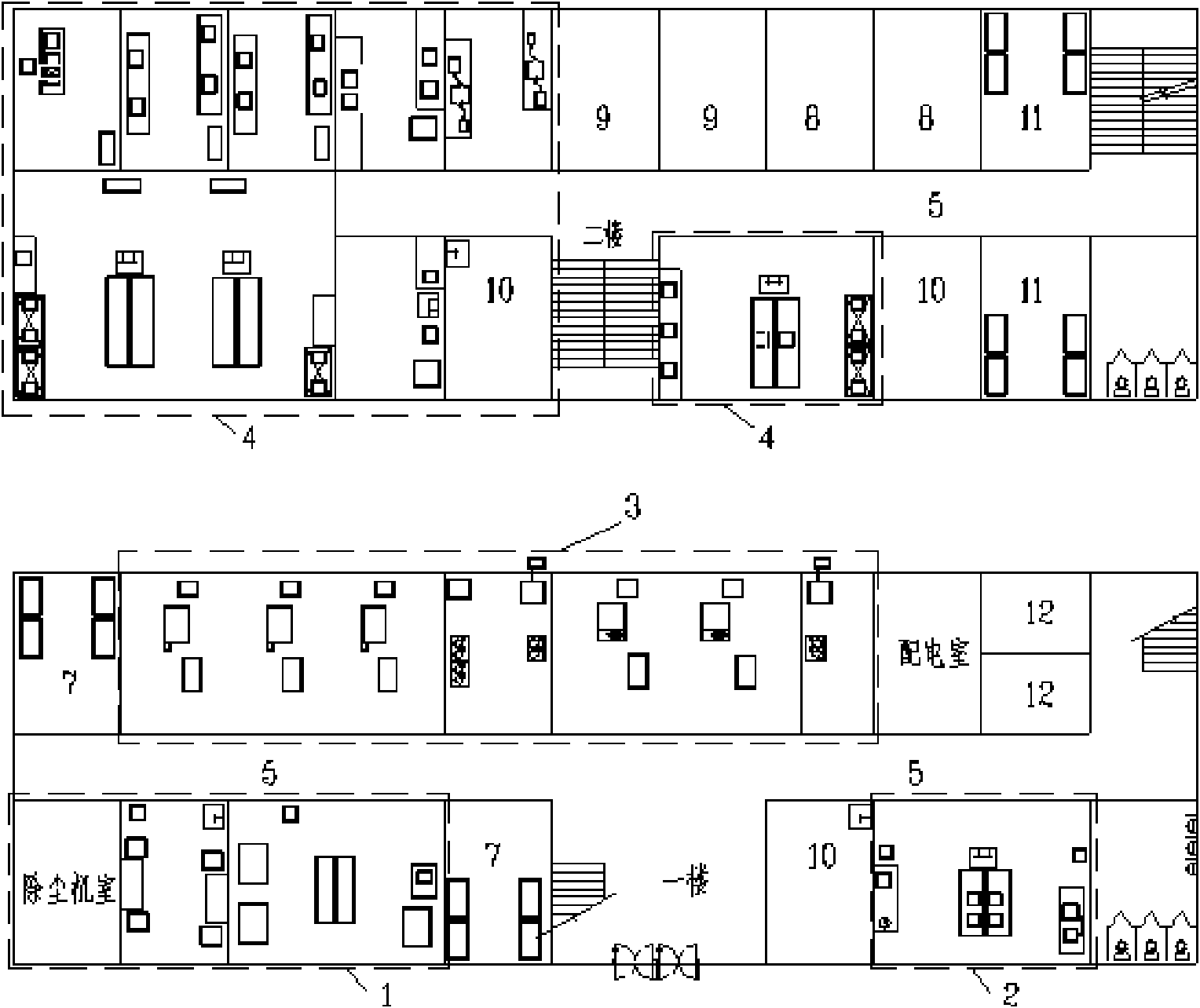

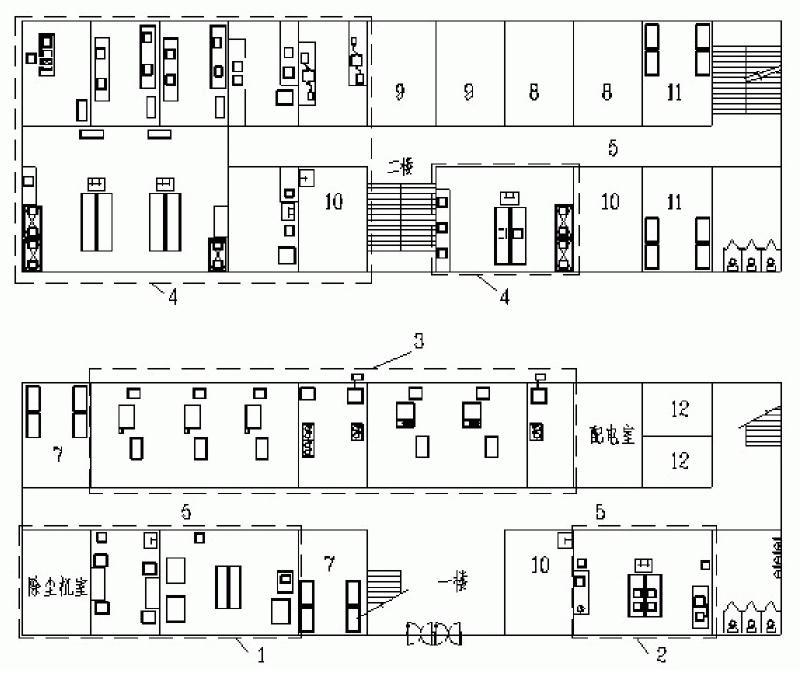

[0021] Embodiment one: if figure 1 As shown, according to the operating characteristics and the functions of each unit in the laboratory of the electrolytic aluminum factory, the laboratory of the inner corridor-style two-story building is divided into four functional modules to match the production capacity of 500,000 tons / year of remelting aluminum ingots The analysis and inspection scale of the electrolytic aluminum plant is a standard configuration. One bay of the room is 3.6m and the depth is 6m. The number of bays in each room depends on the equipment configuration requirements. It can be one, two or three. The total construction area about 1150m 2 .

[0022] The partition situation is: sample preparation module 1, which is equipped with sample preparation equipment for crushing, briquetting, turning, and drilling. The number of various equipment can range from 1 to 3 sets (sets) according to needs; physical properties The test module 2 is equipped with alumina physica...

Embodiment 2

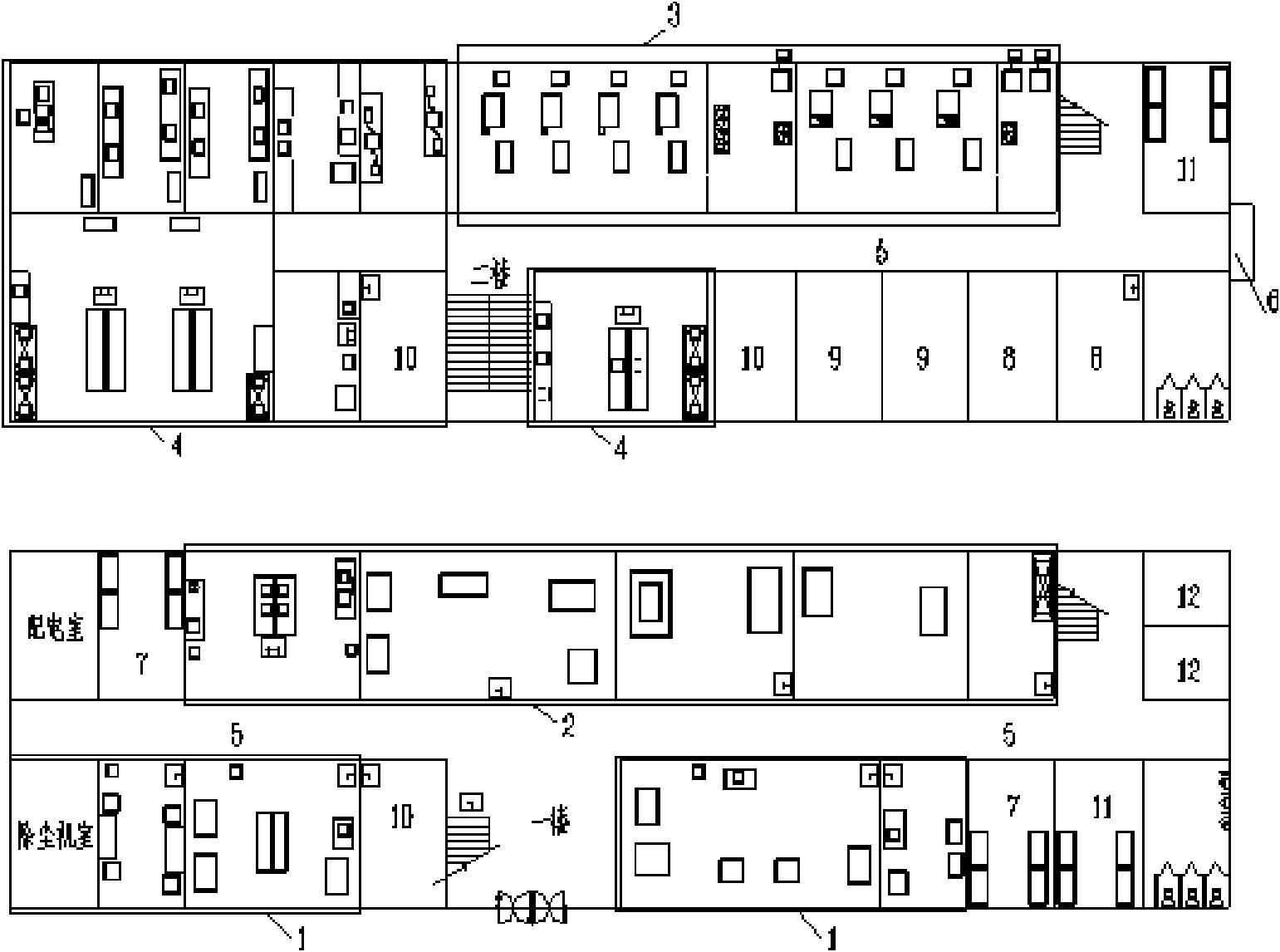

[0025] Example two such as figure 2 shown. According to the operating characteristics, according to the extension of the functions of each unit in the laboratory of the electrolytic aluminum plant that produces aluminum or aluminum alloy plates and strip products, the laboratory of the two-storey building with inner corridors is divided into four functional modules to cooperate with the laboratory. The analysis and inspection scale of the electrolytic aluminum plant with a total production capacity of 500,000 tons / year including remelted aluminum ingots, plates, and strips is a standard configuration. One bay of the room is 3.6m, and the depth is 6 meters. The number depends on the equipment configuration needs, it can be one, two or three, with a total construction area of about 1500m 2 .

[0026] The partition situation is: sample preparation module 1, which is equipped with sample preparation equipment for crushing, briquetting, turning, drilling, milling, planing, saw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com