Hot air deicing refrigeration system of single-plate plate ice machine

A refrigeration system and plate ice technology, applied in the field of hot gas deicing refrigeration system of a single-group plate ice machine, can solve the problems of low exhaust pressure, low suction pressure, unstable refrigeration system, etc., to increase pressure and increase speed , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

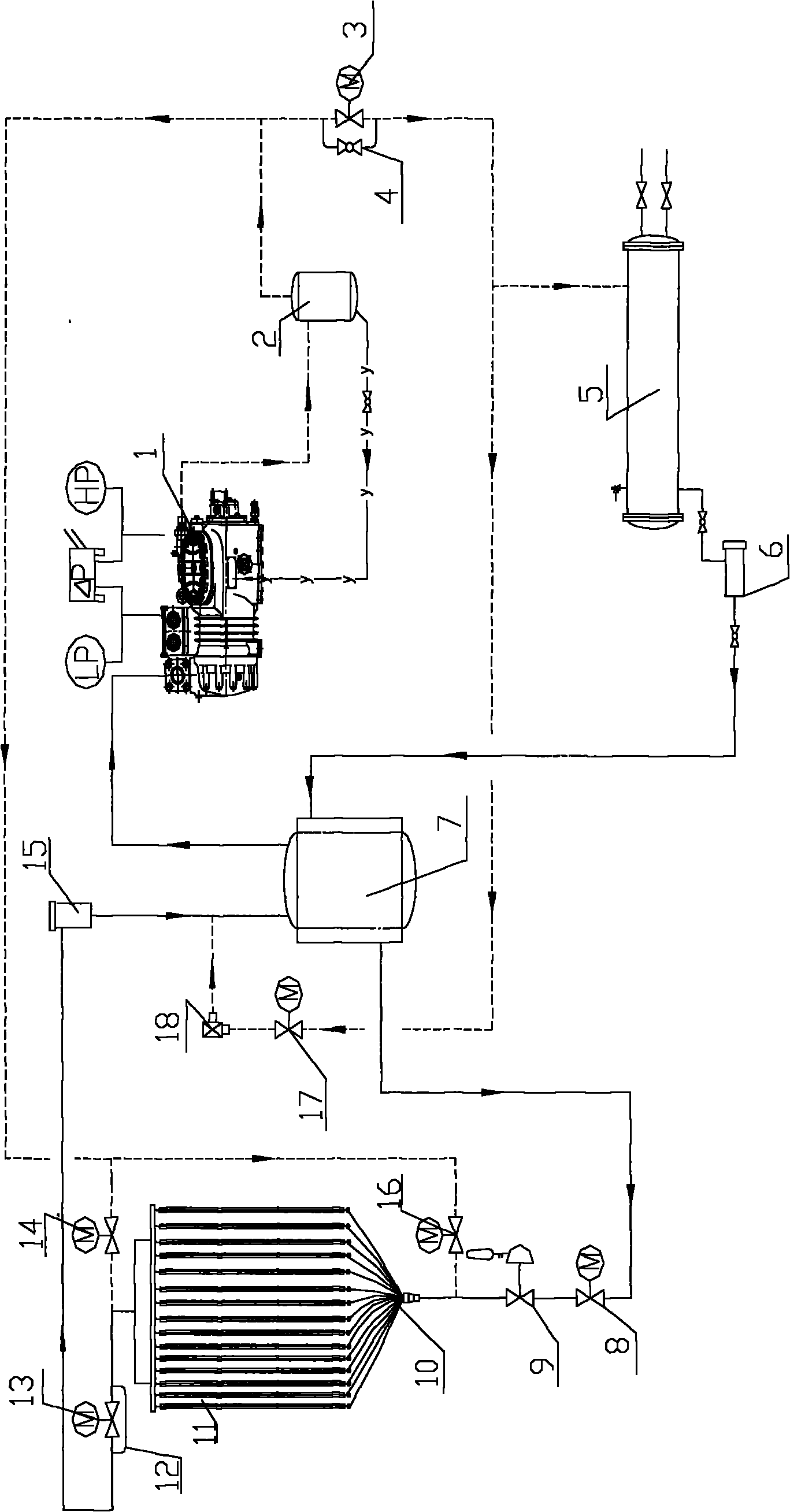

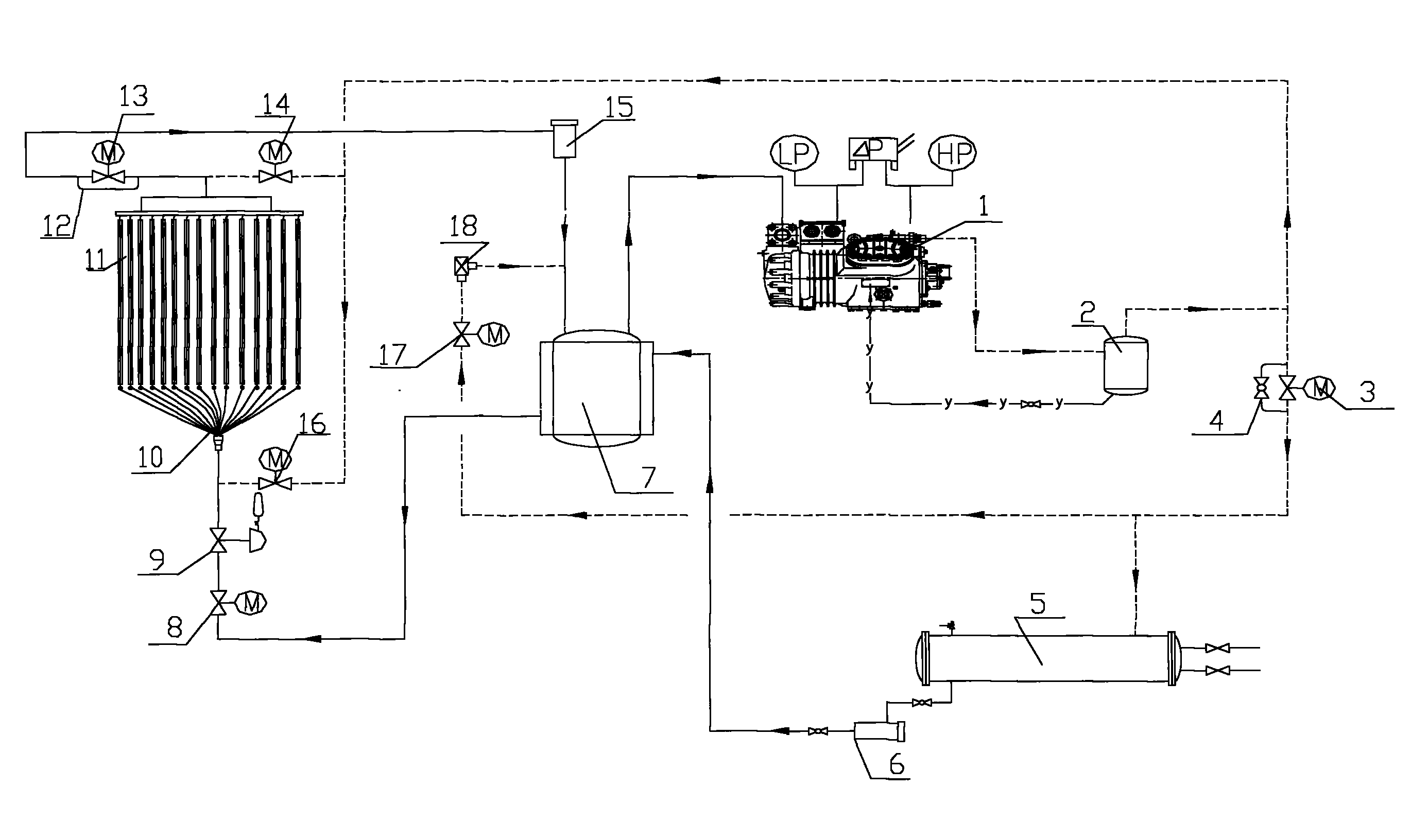

[0010] For the sake of reference and clarity, the meanings represented by the symbols in the accompanying drawings are explained as follows:

[0011] 1. Refrigeration compressor, 2. High-efficiency oil separator, 3. Differential pressure solenoid valve, 4. Exhaust bypass valve, 5. Water-cooled condenser, 6. Liquid supply filter, 7. Gas-liquid separator with heat exchange , 8. Liquid supply solenoid valve, 9. Thermal expansion valve, 10. Liquid separator and capillary tube, 11. Plate ice plate heat exchanger, 12. Short circulation pipe, 13. Return air solenoid valve, 14. Return air hot gas Solenoid valve, 15, return air filter, 16, liquid supply hot gas solenoid valve, 17, bypass solenoid valve, 18, KVC pressure control valve.

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com