Optical coupler

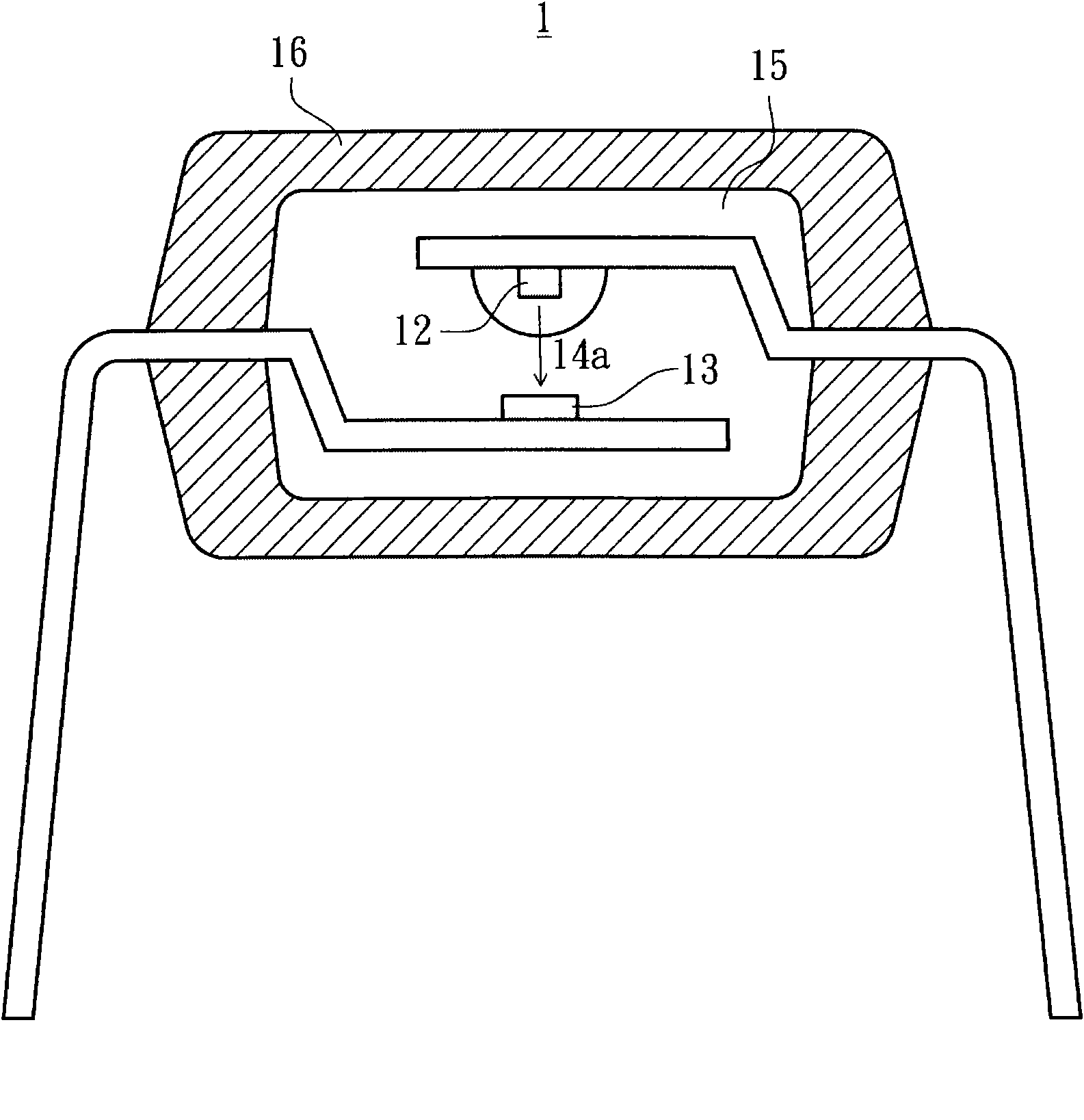

An opto-coupler and light-sensing technology, applied in the field of opto-couplers, can solve the problems of incompetent working environment, low light transmittance, large loss of light beam 14a, etc., and achieve the effect of avoiding the phenomenon of tip discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

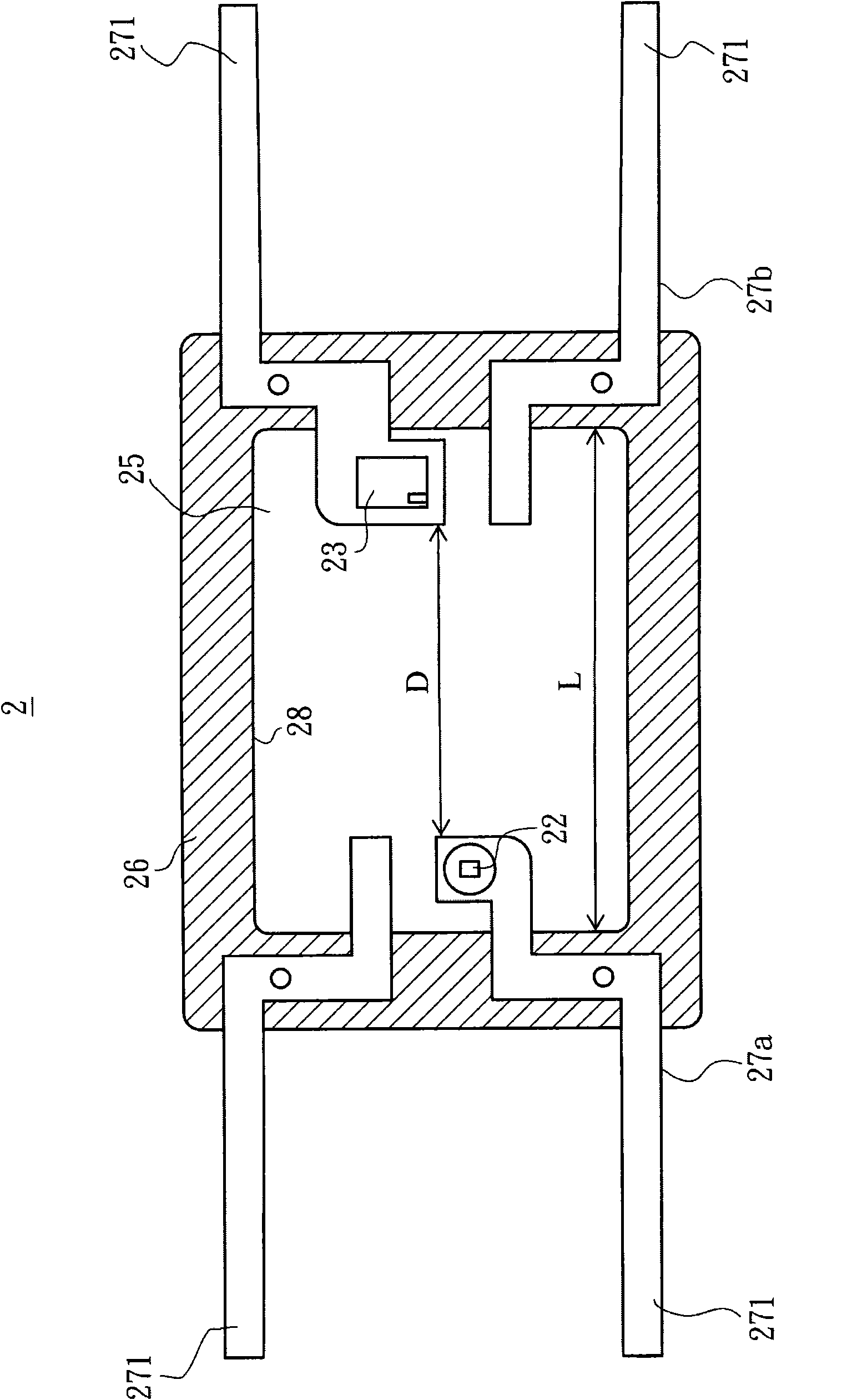

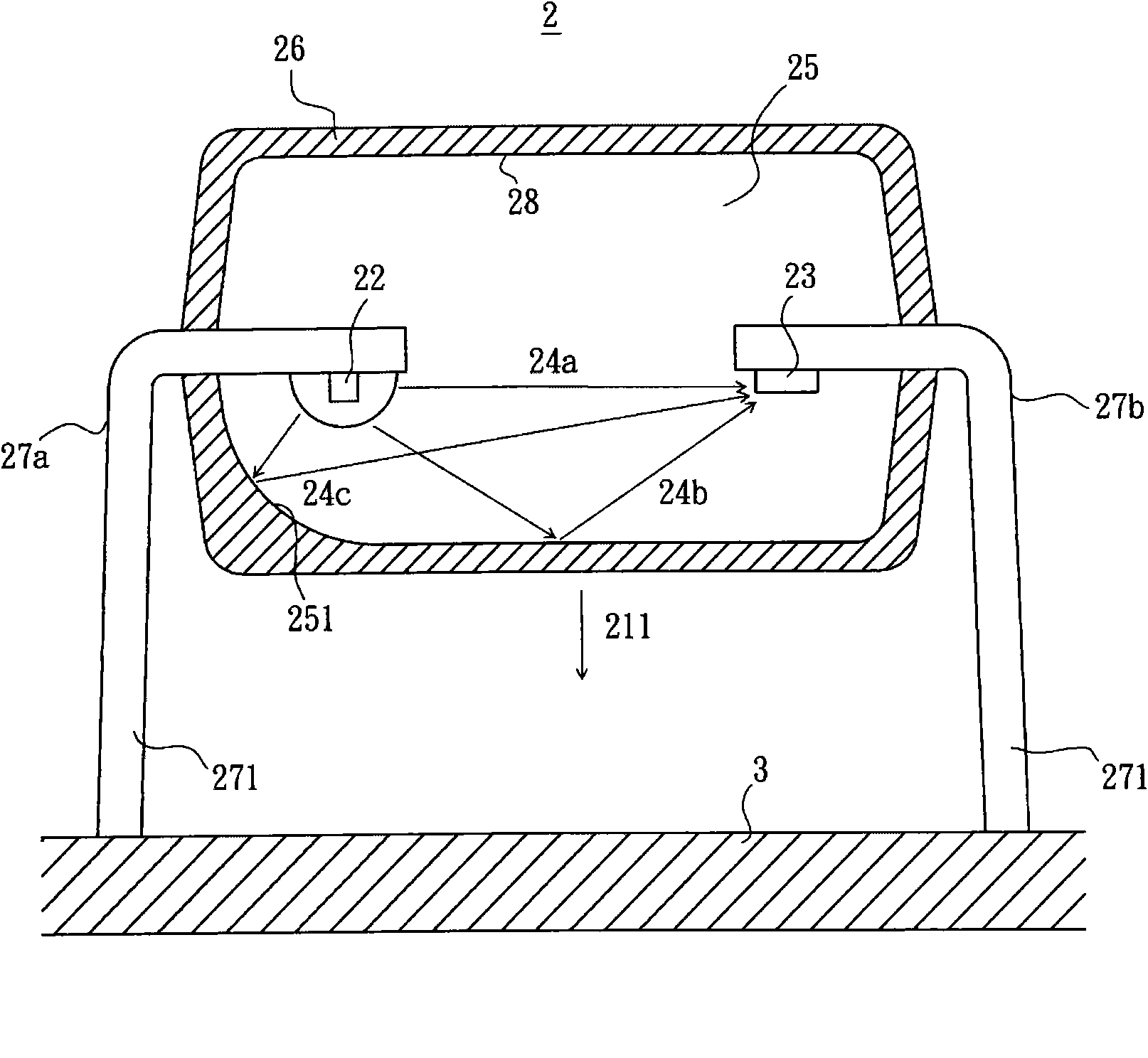

[0027] Please also see figure 2 and image 3 , the optical coupler 2 disclosed in the present invention includes a light-emitting chip 22 , a photosensitive chip 23 , a transparent inner package 25 and an outer package 26 . Wherein, the light-emitting chip 22 and the light-sensitive chip 23 are arranged on the same plane, and are also arranged toward a direction 211 of the optical coupler 2 .

[0028] After receiving an input electrical signal, the light emitting chip 22 is suitable for generating and emitting the first part 24c of the light beam, the second part 24b of the light beam and the third part 24a of the light beam, and the photosensitive chip 23 receives the first part 24c, the second part 24b and the third part 24a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com