Elevator

An elevator and elevator car technology, applied in the elevator field, can solve the problems of short feedback response time, cost, complexity, etc., and achieve the effect of reducing maintenance workload and cost, and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

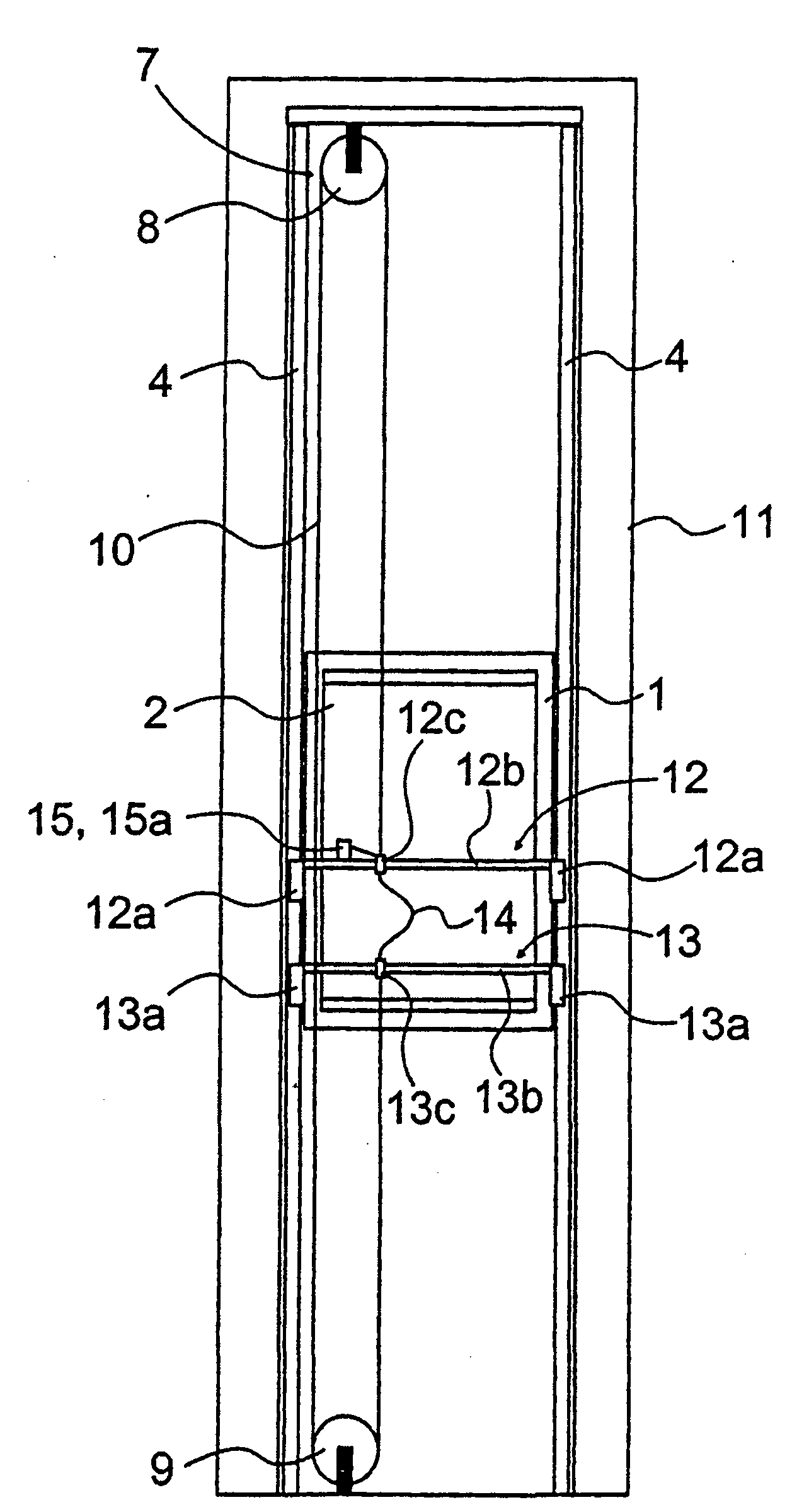

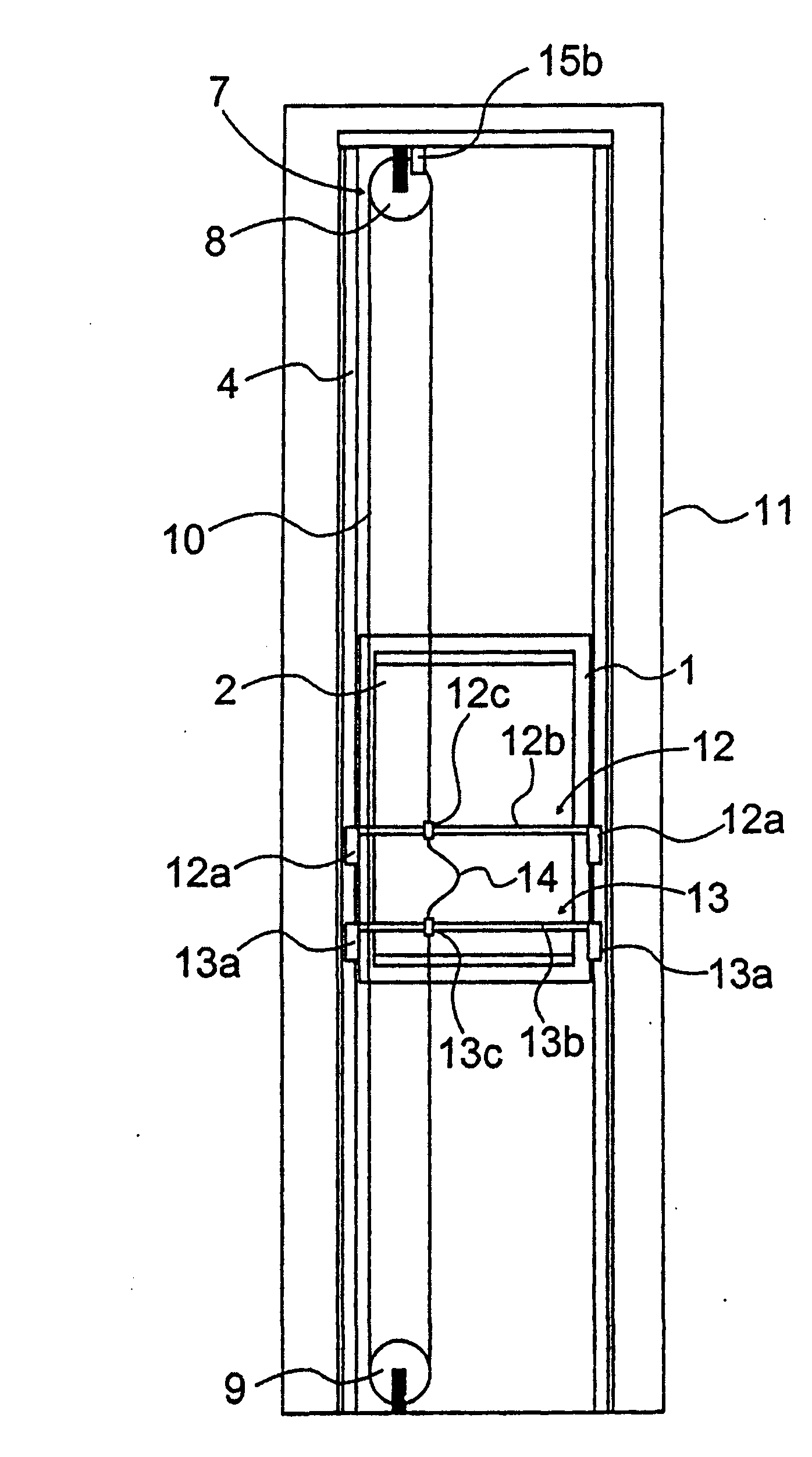

[0038] figure 1 A simplified schematic rear view showing an elevator in which an embodiment of the safety equipment of the present invention is employed. For the sake of clarity, some parts of the elevator, including the traction machine and ropes and related assemblies, and also the sliding guides on the guide rails and the guide rollers, have been omitted from the drawing. An elevator car 2 fitted in a car frame 1 and driven by a separate traction machine (not shown in the figure) is arranged to move in an elevator hoistway 11 along guide rails 4 in a substantially vertical direction. sports. In the upper part of the elevator shaft 11 there is a governor pulley 8 included in the governor 7 and in the lower part a deflection pulley 9 included in the governor 7 . Fitted in loops around these pulleys is a governor rope 10 under appropriate tension.

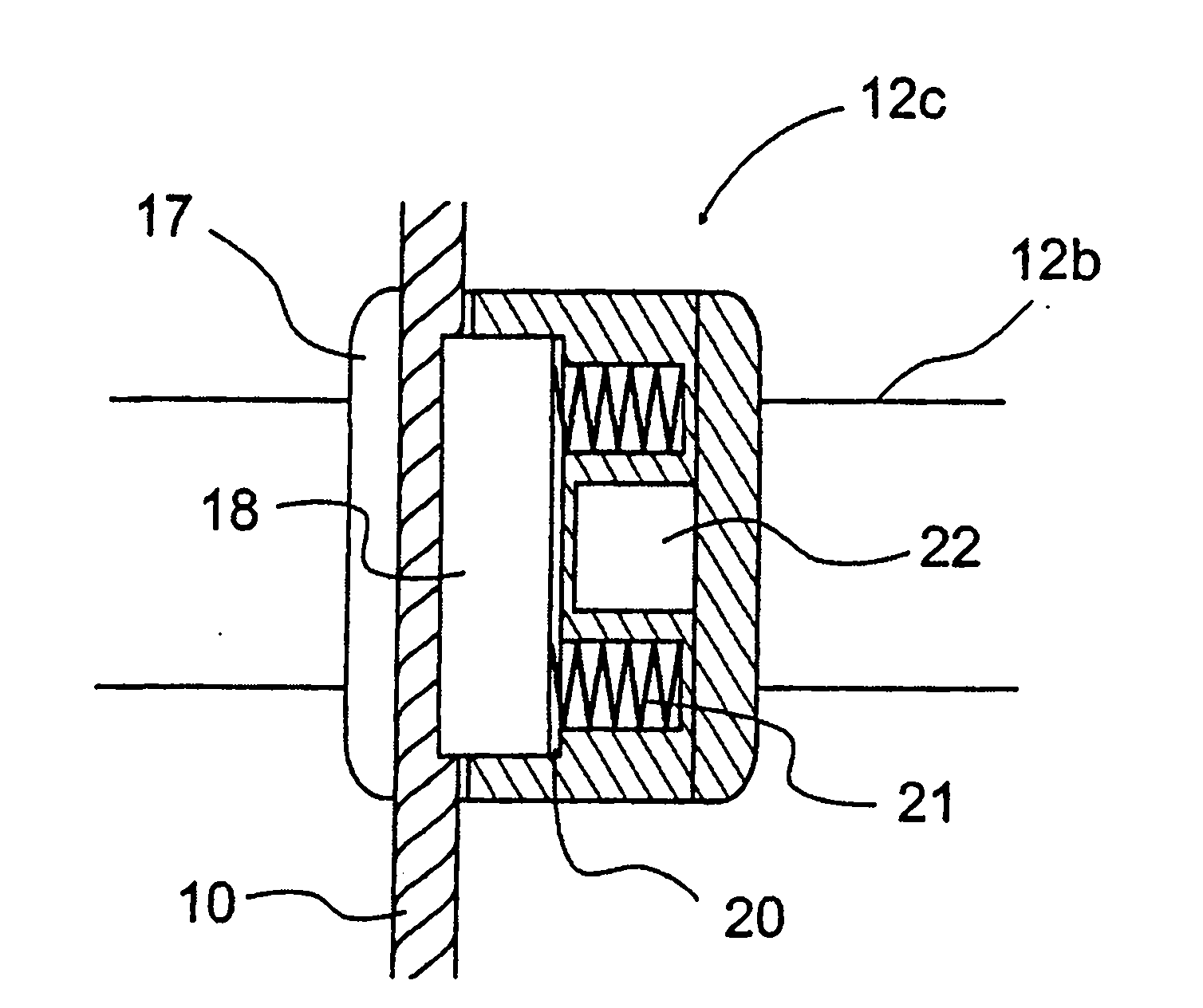

[0039] The car frame 1 is provided with two safety devices 12 and 13, each comprising two safety mechanisms, mounted on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com