Electric motor for compressor, compressor, and freezing cycle device

A technology for compressors and motors, which is applied in the field of compressors, refrigeration cycle devices, and motors for compressors. It can solve the problems of high component prices, unrealizable stator cores, and reduced efficiency of single-phase induction motors, etc., to increase the starting speed. Moment, the effect of suppressing the rise in component prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

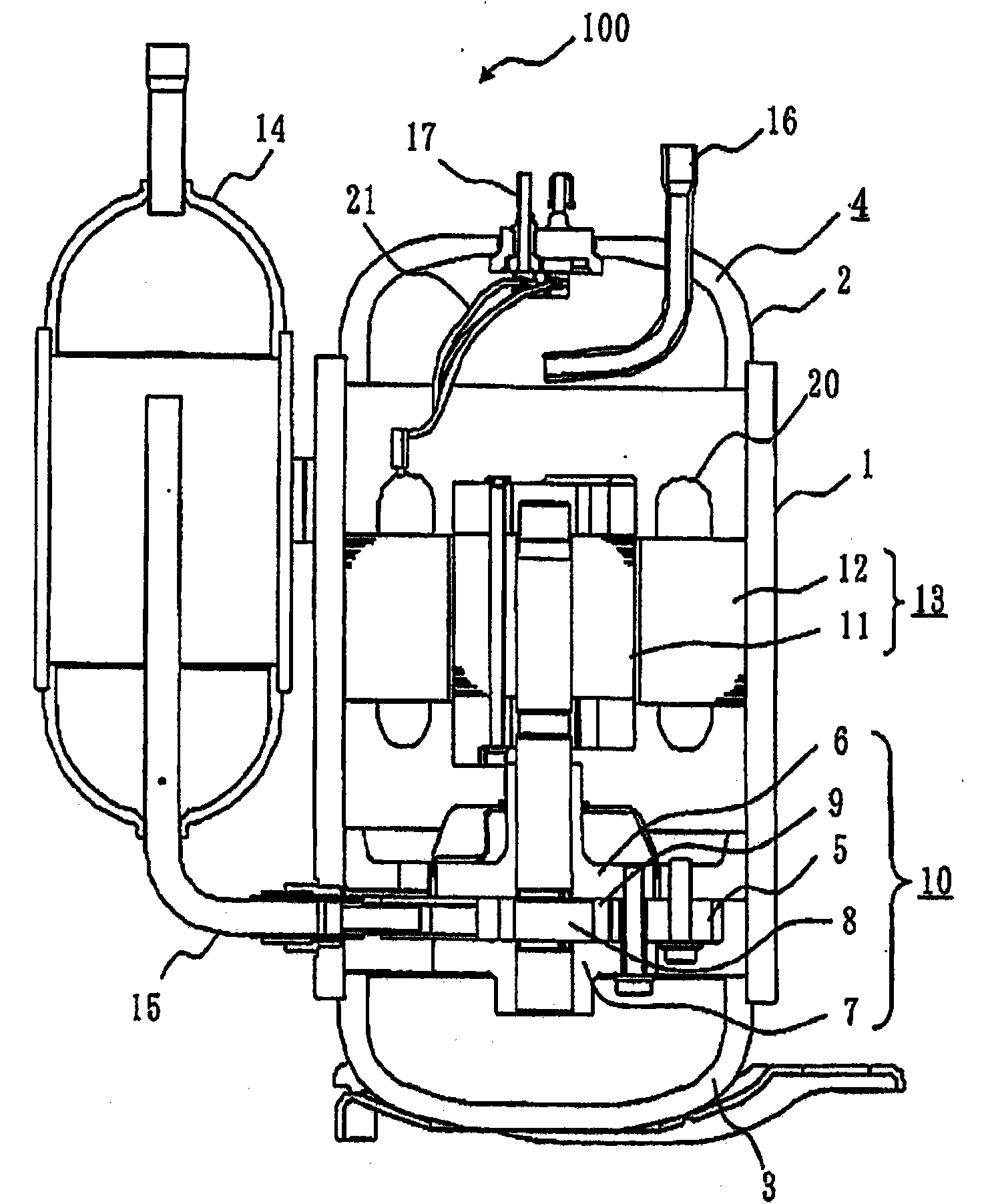

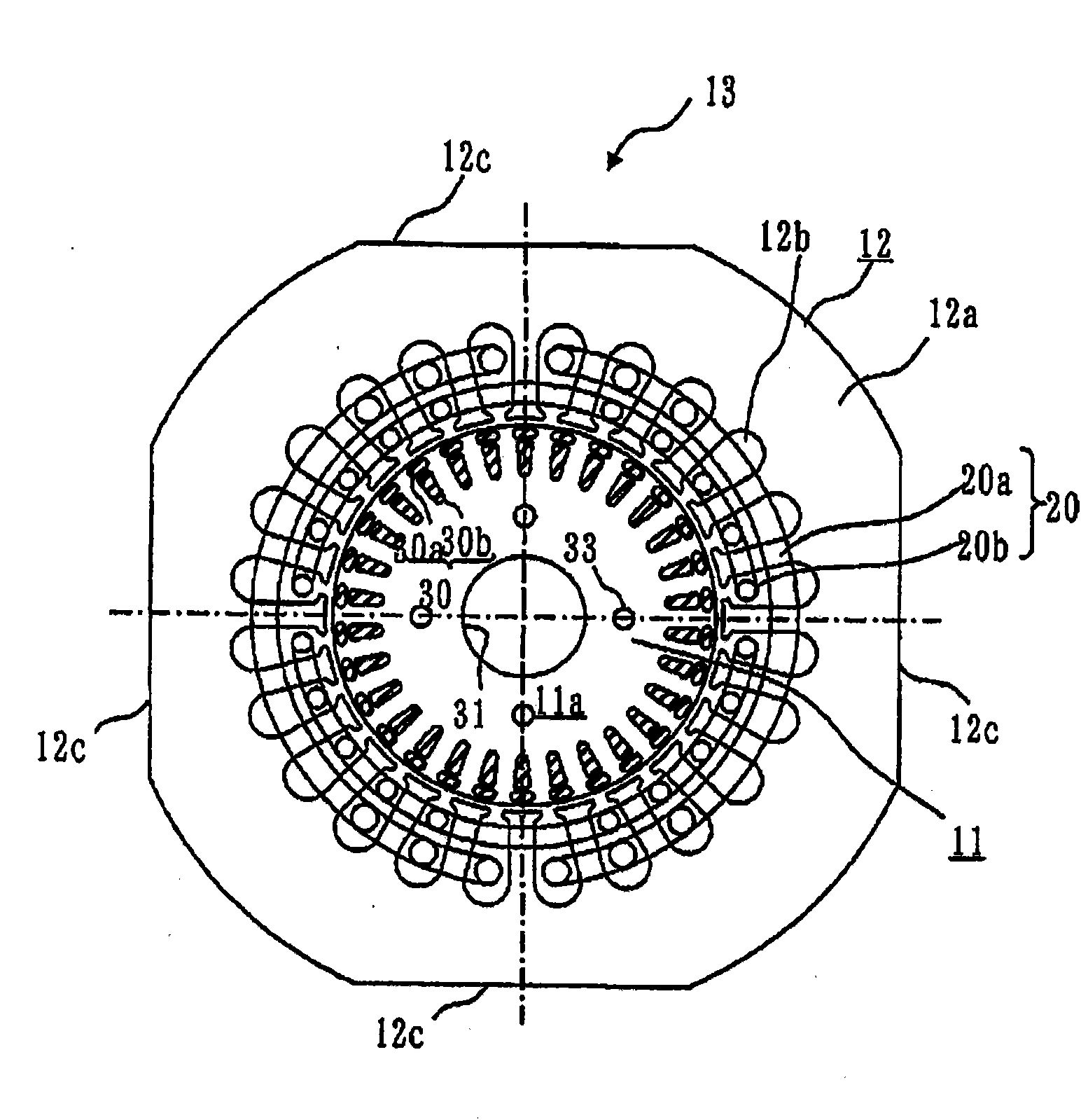

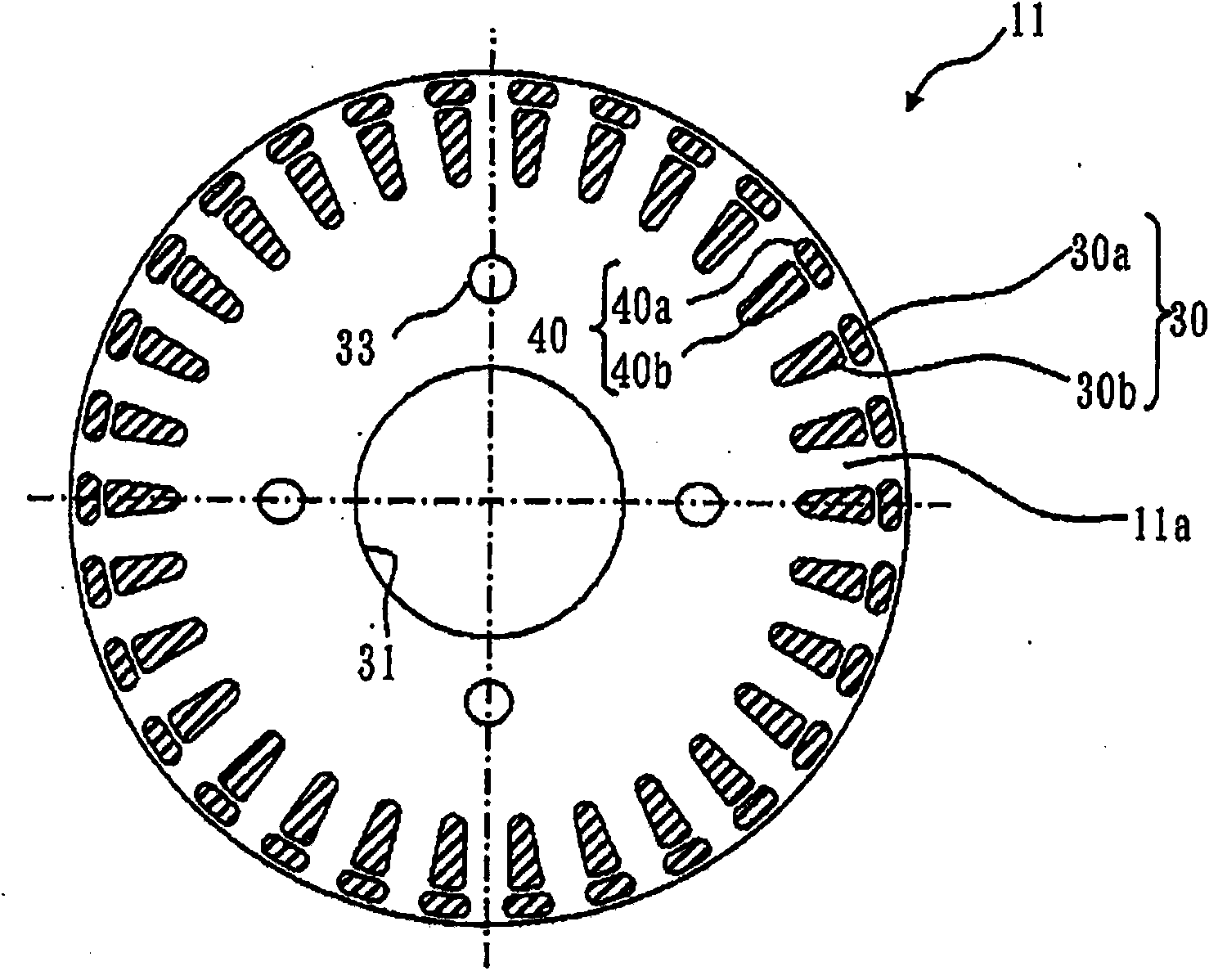

[0100] Figure 1 to Figure 14 is a diagram showing Embodiment 1, figure 1 is a longitudinal sectional view of the rotary compressor 100, figure 2 is a transverse sectional view showing the electric element 13, image 3 is a transverse cross-sectional view showing the rotor 11 of the electric element 13, Figure 4 is a perspective view showing the rotor 11 of the electric element 13, Figure 5 is a side view of the rotor 11 provided with a cutout 34 on the end ring 32, Image 6 is a side view of the rotor 11 provided with end ring ventilation holes 32a, Figure 7 It is a transverse cross-sectional view of the vicinity of the electric element 13 showing an example in which ventilation holes are provided on the stator 12 side, Figure 8 , Figure 9 is a transverse sectional view of the groove of the rotor 11, Figure 10 is a graph showing the relationship between the volume ratio of the end ring 32 and the rotor core 11a, the secondary resistance R2, and the motor efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com