Method for manufacturing moulded and coded confections

A confectionary and coding technology, which is applied in confectionary, confectionary industry, food science, etc., can solve the problems of lack of flexibility and inability to change the filling material of the mold cavity, and achieve the effect of reducing the replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

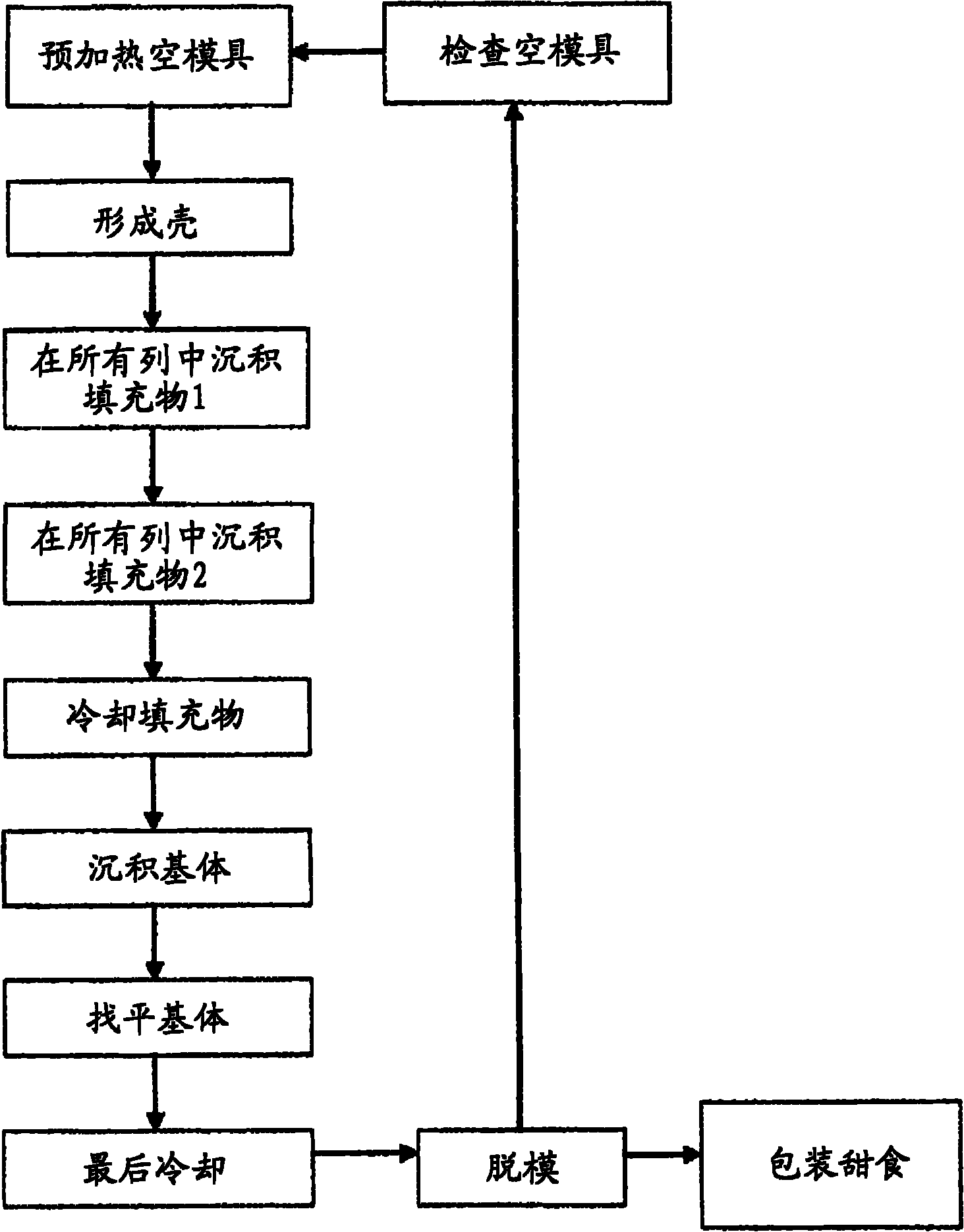

[0032] The method according to the first embodiment of the present invention defined above will be described in detail below.

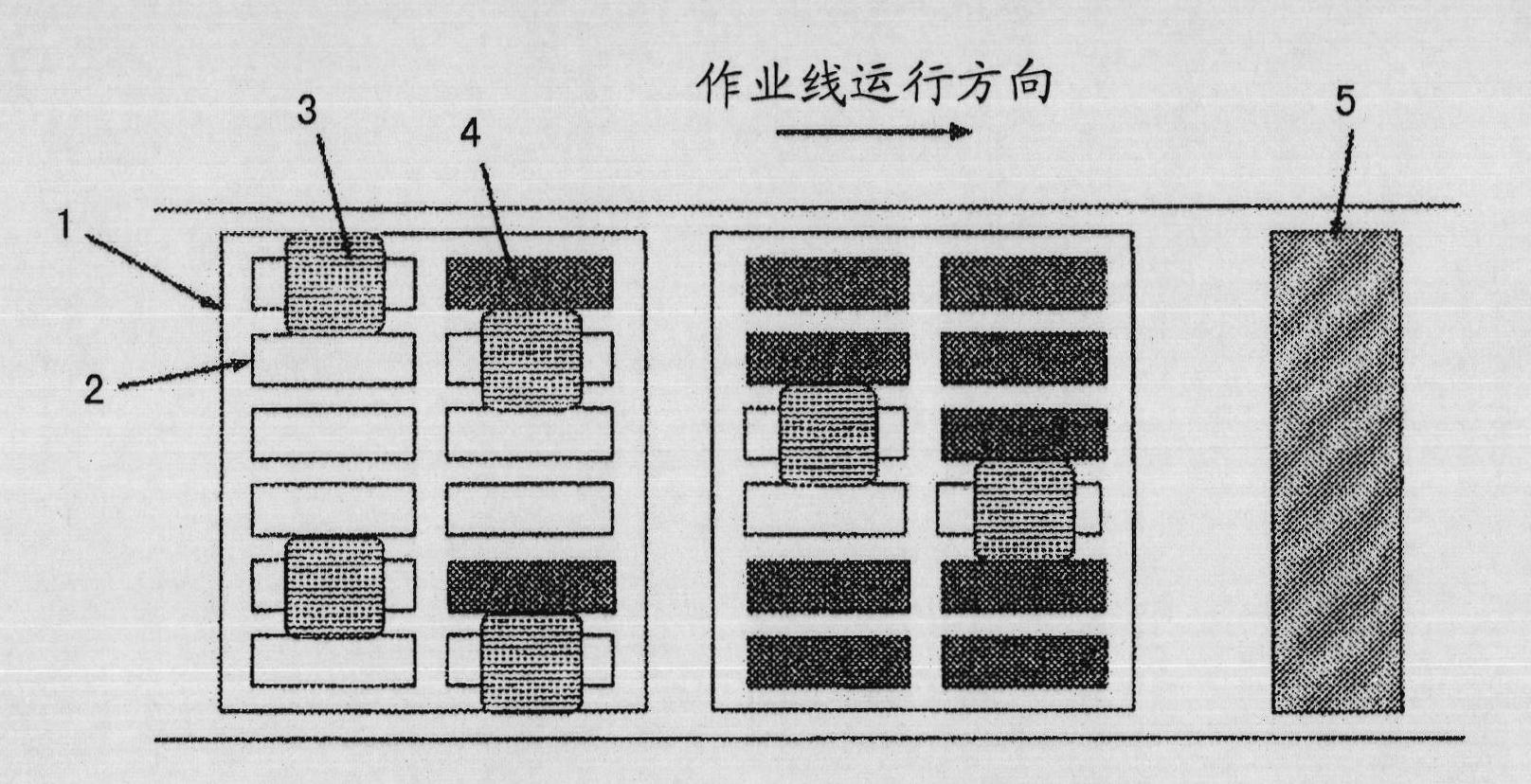

[0033] (i) deposition

[0034] The method comprises the step of depositing edible material into cavities of a mold to produce a molded confection, the mold comprising two or more rows of cavities.

[0035] The edible material may be any edible material conventionally used in the production of molded confectionery. The edible material preferably includes at least one of chocolate, cream, caramel, toffee, fruit and nuts, and more preferably includes chocolate.

[0036] "Chocolate" includes plain chocolate, dark chocolate, milk chocolate (including home milk chocolate) and white chocolate. These kinds of chocolate may be as defined in the EU Chocolate Directive (Directive 200 / 36 / EC). However, edible materials may also include compound chocolate, which does not comply with this Directive, eg, chocolate containing vegetable fat above the limits set out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com