Intelligent kelp automatic knot tying machine

An automatic knotting and intelligent technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of restricting the export of kelp and the difficulty of hiring skilled workers in kelp processing plants, saving labor resources and improving knotting efficiency. , the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

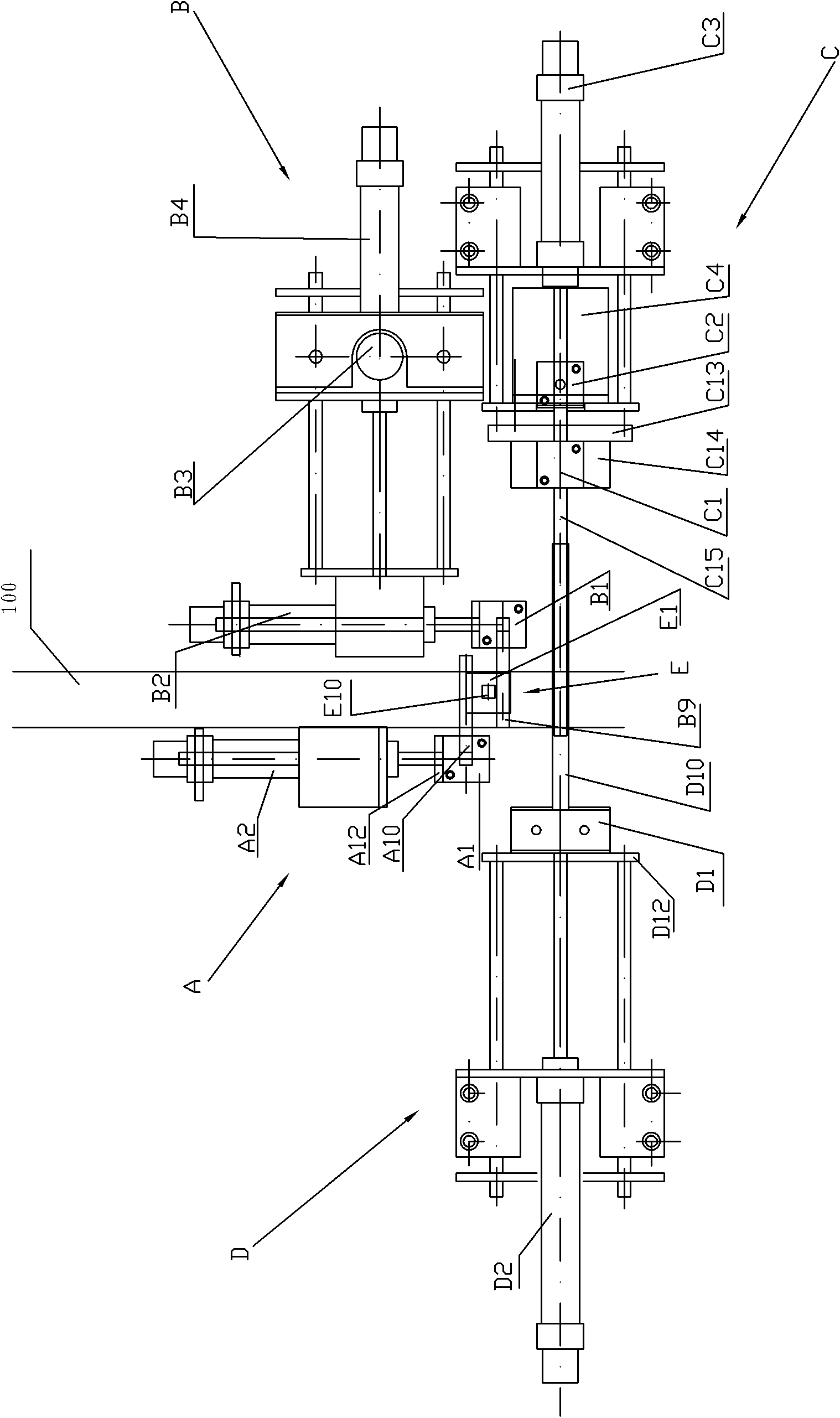

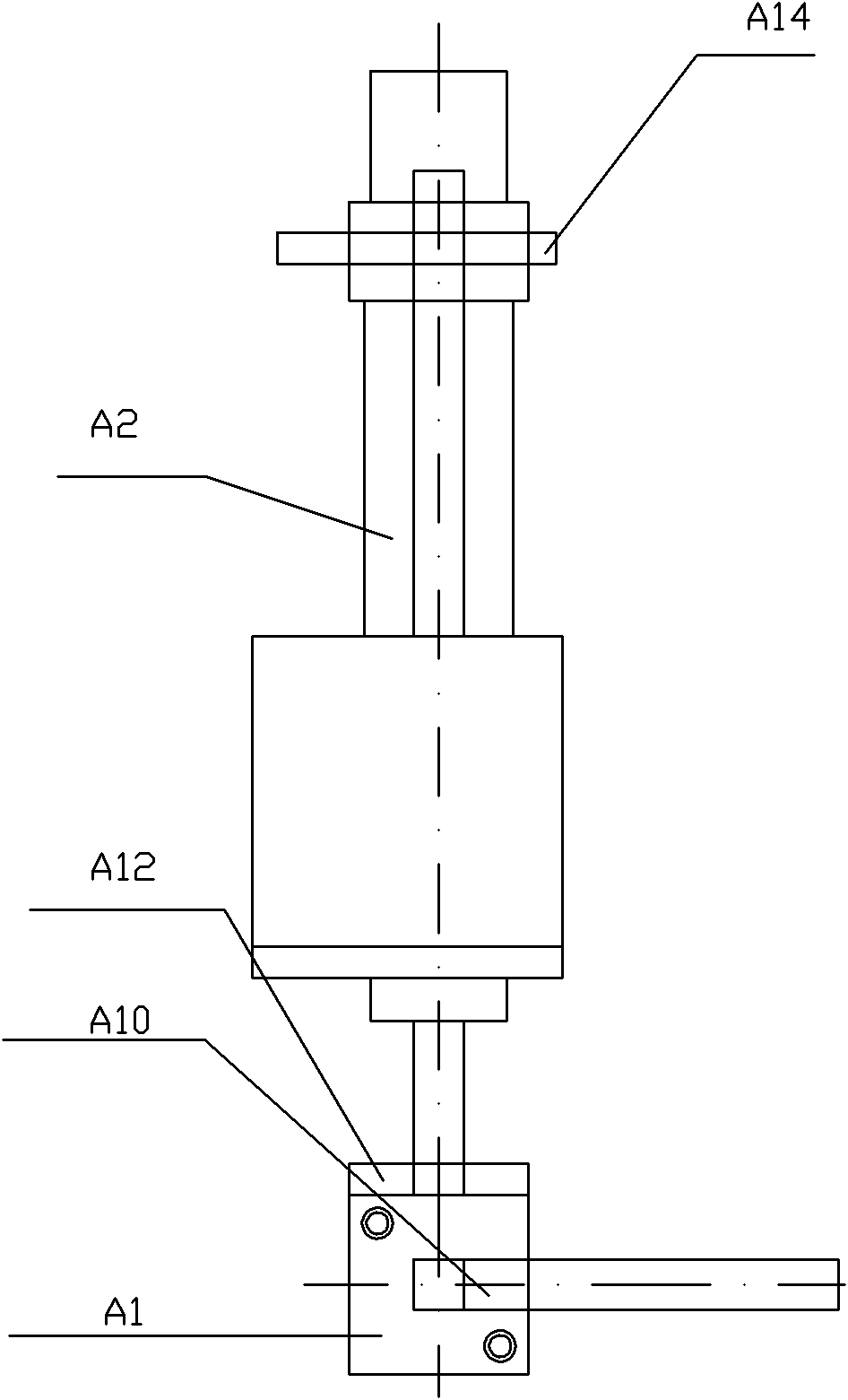

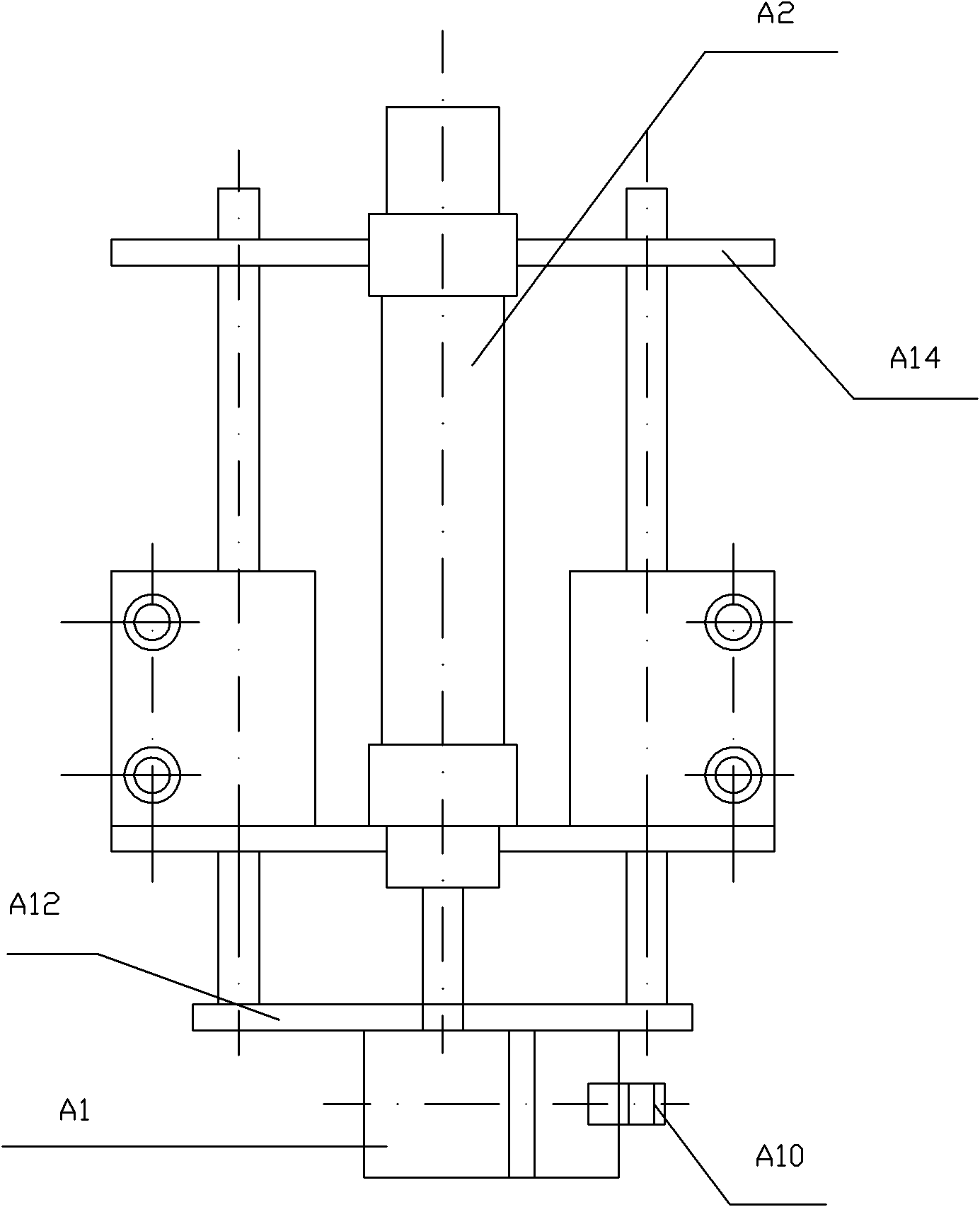

[0023] Examples, see figure 1 As shown, an intelligent kelp automatic knotting machine of the present invention includes a base (not shown in the figure) and an automatic feeding mechanism A mounted on the base, a knotting feeding mechanism B, a winding mechanism C, and a knotting mechanism D , the material cutting mechanism E and the PLC microcomputer control system used to control the mutual cooperation of various mechanisms; Direction is the first clamping jaw A10 that can be used for feeding laterally and can move laterally; , the second jaw B9 that moves horizontally and vertically in three-dimensional directions; the cutting mechanism E is set between the first jaw A10 and the second jaw B9, and the cutting mechanism E is provided with a cutting knife E10 that can produce a cutting action ; The knotting mechanism D is located at the end of the kelp feeding line and on the same side as the automatic feeding mechanism A, and the knotting mechanism D is provided with a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com