Agricultural product deep processing vacuum energy device system engineering

A system engineering and deep processing technology, applied in the field of system engineering of vacuum energy devices for deep processing of agricultural products, can solve problems such as failure to achieve added value, loss of materials due to rot, and inability to keep fresh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

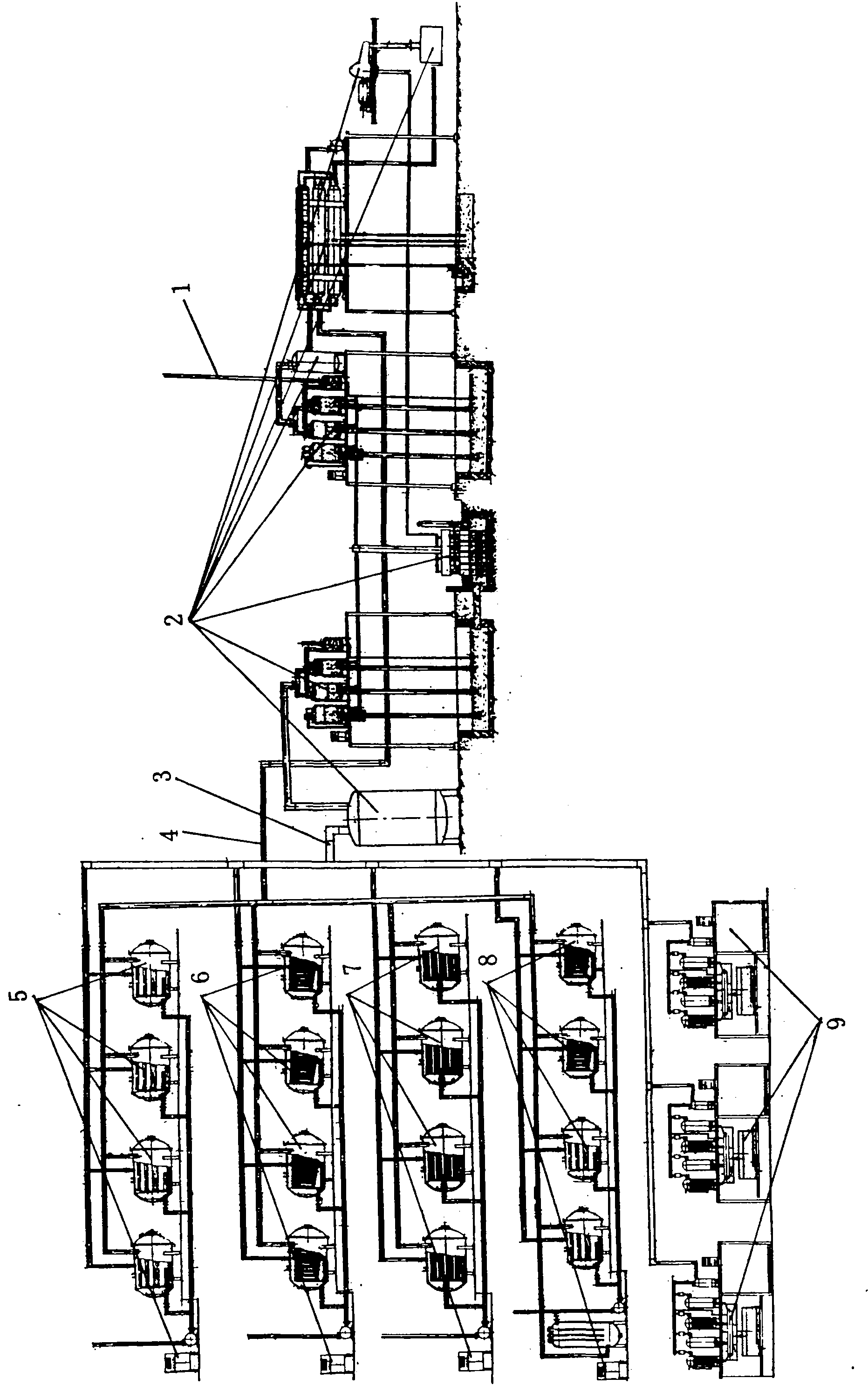

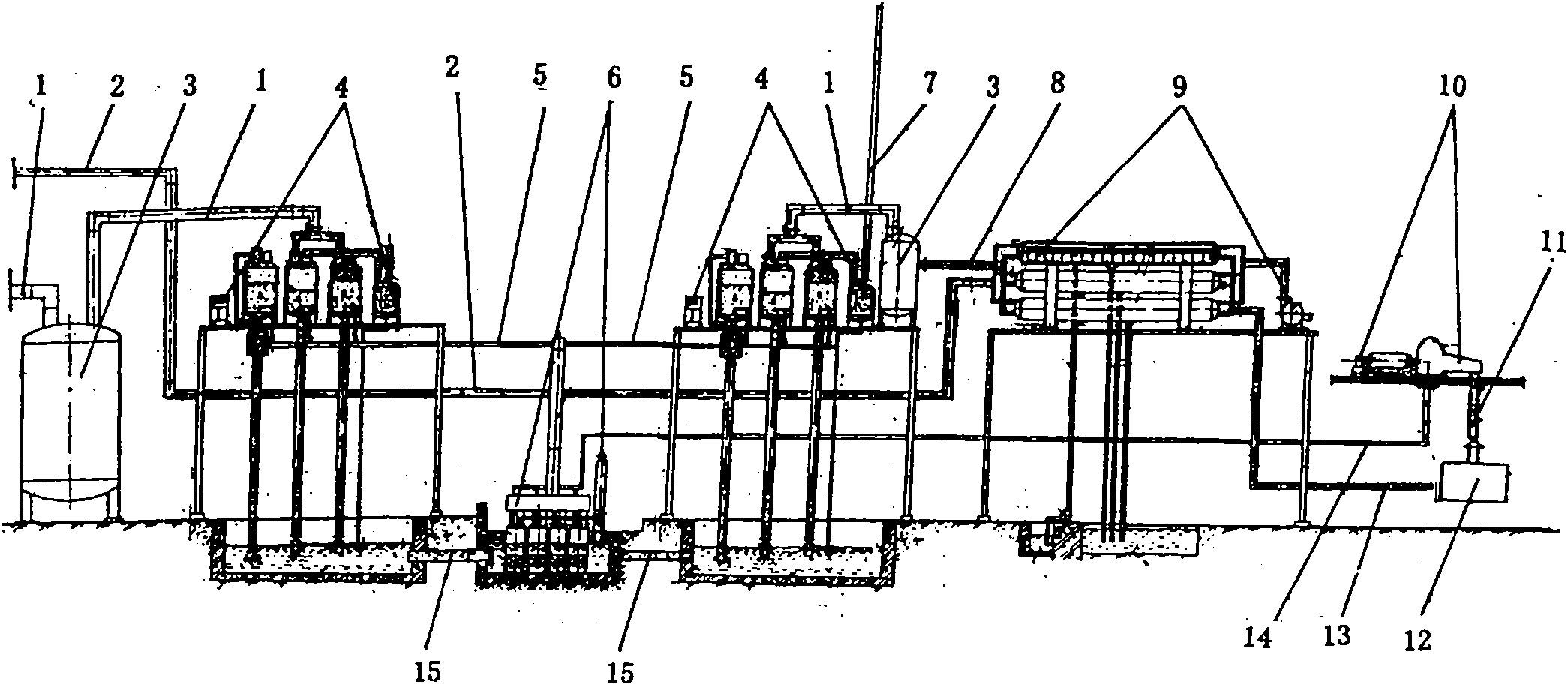

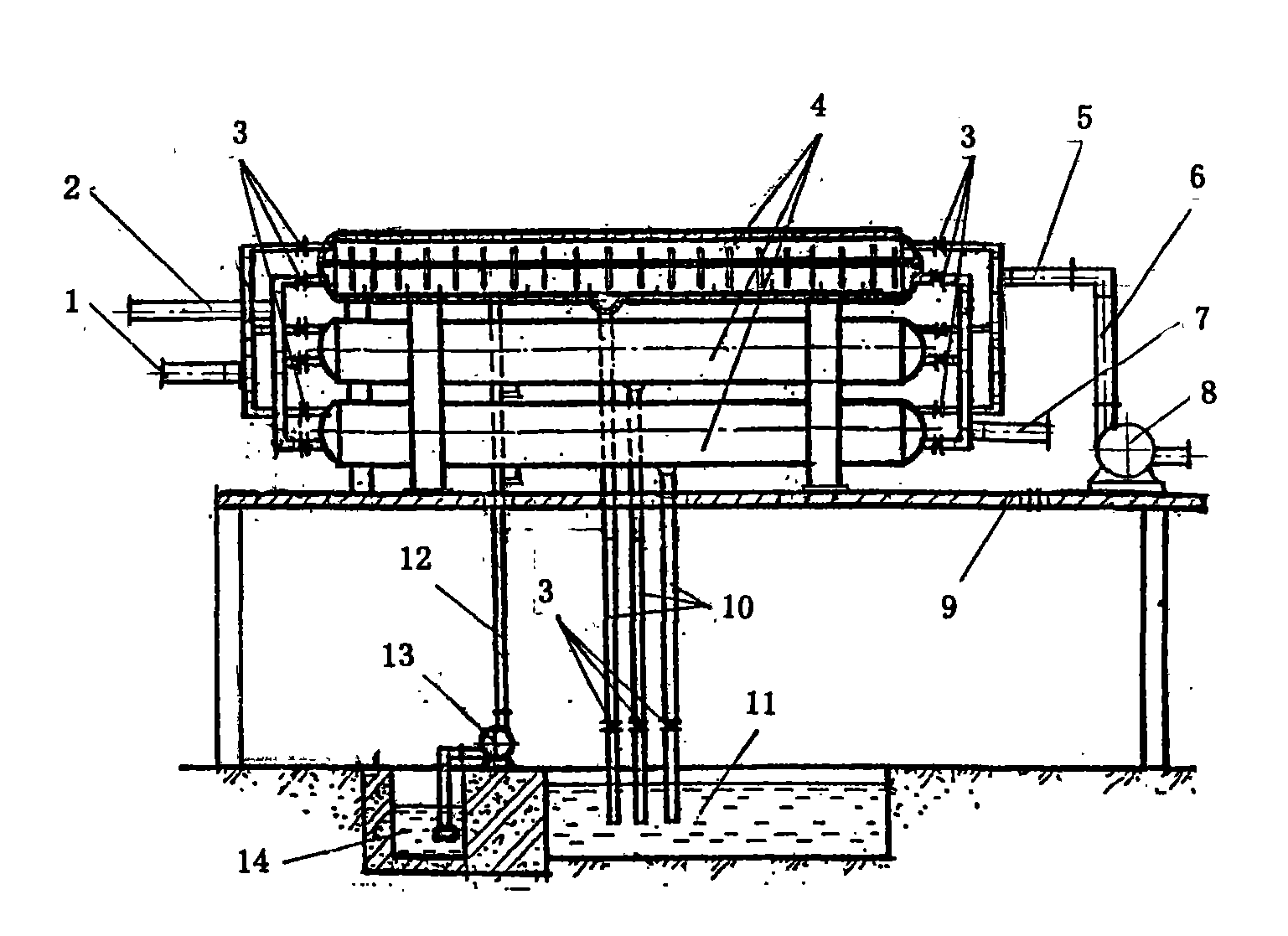

[0055] Attached below figure 1 The dynamic operation of the present invention is generally described: by figure 1 As shown, the vacuum energy thermal power generation system 2 completes two tasks: using the residual steam discharged from the thermal power generation steam turbine as the power, obtaining vacuum energy on a large scale and converting the waste heat discharged from the flue of the boiler flue into clean hot air energy. Through the vacuum pipeline 3, heat The air pipeline 4 transmits the large-scale vacuum energy and clean hot air energy to the material general-purpose vacuum heat flow dehydration drying and preservation system 5, the grain type vacuum heat flow dehydration drying preservation system 6, the tea type vacuum heat flow dehydration drying preservation system 7, and food vacuum heat flow cooking System 8, food vacuum frying and drying system 9, so that each system implements vacuum heat flow drying and vacuum frying technology, realizes large-scale, lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com