Industrialized vacuum feeding device for tobacco raw material

A technology of feeding device and raw material, which is applied to tobacco, spraying device, tobacco preparation and other directions, can solve the problems of occupying production space and equipment costs, reducing production efficiency, long balancing time, etc., to reduce material and liquid loss, improve production efficiency, Guaranteed full absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

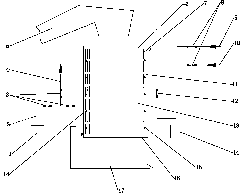

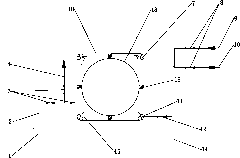

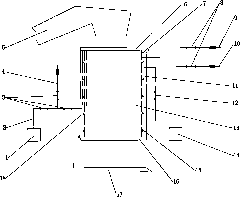

[0015] The structure of the present invention is described in the Summary of the Invention. Wherein: the external sealed warehouse (18) and the meshed tobacco raw material warehouse (13) are prepared according to accompanying drawings and conventional methods with commercially available materials; all the other parts are purchased from the market. Then according to the assembling connection of accompanying drawing, obtain the present invention. The automatic control system is composed of a commercially available computer, a programmable logic controller PLC, and a servo drive system.

[0016] The operating process of the present invention is:

[0017] Open the upper movable airtight door 6, close the lower airtight door 16, and the feeding mechanism 5 evenly enters the tobacco raw material into the mesh tobacco raw material warehouse 13; after feeding, close the upper movable airtight door 6, and the automatic control system operates the electromagnetic control valve 3 Close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com