Quick hot blank extracting device with temperature sorting function

A sorting and billet technology, which is applied in the field of hot billet rapid extraction device, can solve the problems of excessive experience requirements and inaccurate billet temperature control, and achieve the effects of increasing sliding inertia, low working environment requirements, and reducing core surface temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

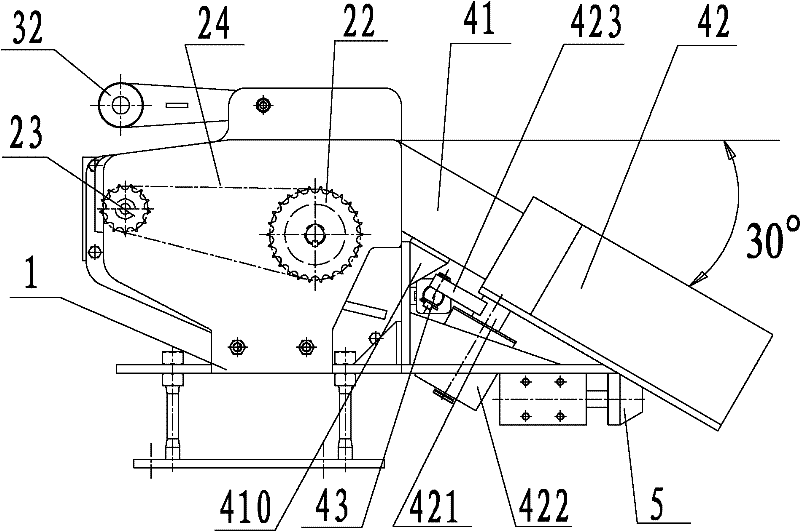

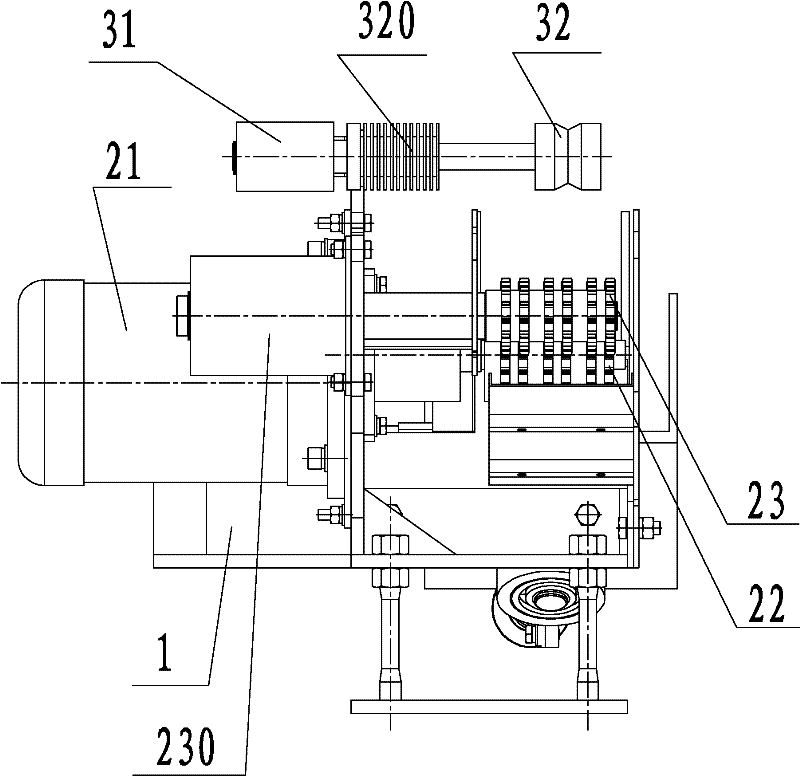

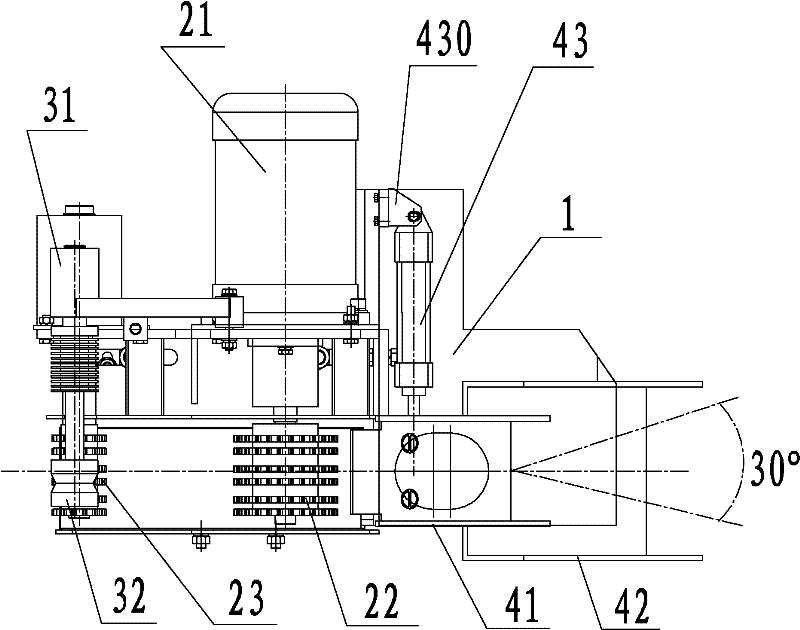

[0016] see Figure 1 to Figure 3 , The hot billet rapid extraction device with temperature sorting function of the present invention includes a base 1, a conveying chain mechanism, a pressing roller mechanism and a sorting mechanism.

[0017] The base 1 can adapt to the reconstruction and installation of the equipment.

[0018] The conveyor chain mechanism is installed on the base 1, and it includes a sprocket drive motor 21, a driving sprocket 22, a driven sprocket 23 and a chain 24, wherein the driven sprocket 22 is located at the upper part of one side of the base 1 and is close to the heating of the blank. The furnace mouth, the driving sprocket 22 is far away from the heating furnace mouth of the billet, and the chain 24 is wound on the driving sprocket 22 and the driven sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com