Individualized vacuum forming mould device and forming method thereof

A technology of vacuum forming and forming method, which is applied in the forming of personalized vacuum molds and in the field of personalized vacuum molds, which can solve the problems of expensive mold making, low cost, and production, and achieve easy-to-love, low-cost, and easy-to-accept. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

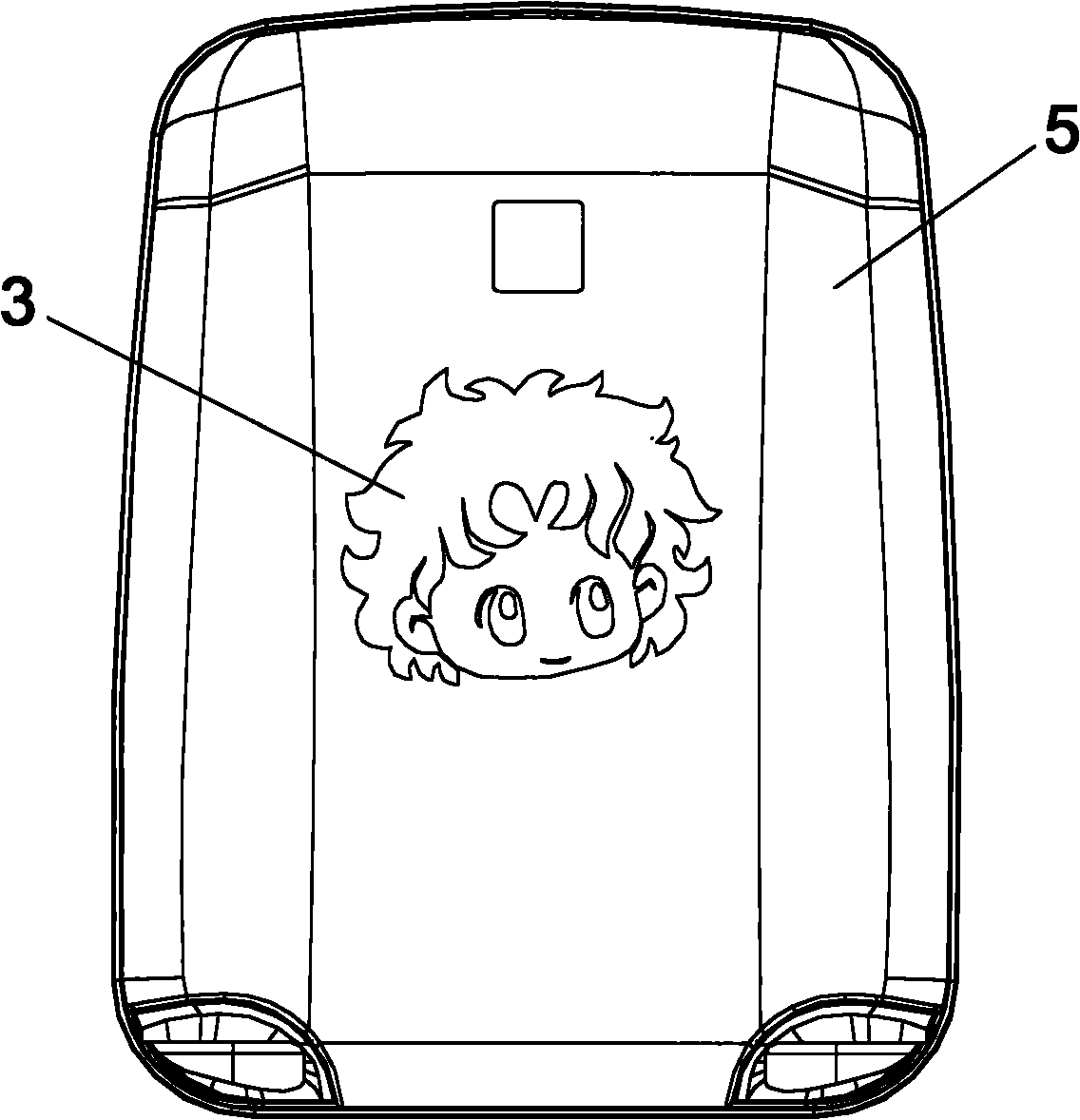

[0027] Such as Figure 5 or Image 6 As shown, the personalized vacuum forming mold of the present invention includes a mold main body 1, and also includes a personalized mold unit 2 customized by consumers, which is used to form convex or concave personalities on the outer surface of the product shell purchased by the consumer. The personalized pattern 3; the personalized mold unit 2 is a replaceable independent part processed from a sheet, and before the flat plastic sheet 6 to be formed is put into the vacuum forming mold device, the personalized mold unit 2 They are placed at appropriate positions on the upper surface of the mold main body 1 to form a single-use or limited-use personalized vacuum forming mold device.

[0028] The personalized pattern 3 can be text, graphics, symbols, or any combination of the above-mentioned three that reflec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com