Printing pressure control device of battery plate printer

A technology of printing pressure and control device, applied in printing presses, rotary printing machines, screen printing machines, etc., can solve the problems of low printing pressure control accuracy, influence of printing efficiency, and low output accuracy, so as to overcome the poor output of printing pressure. Balanced, printing pressure output is balanced, and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

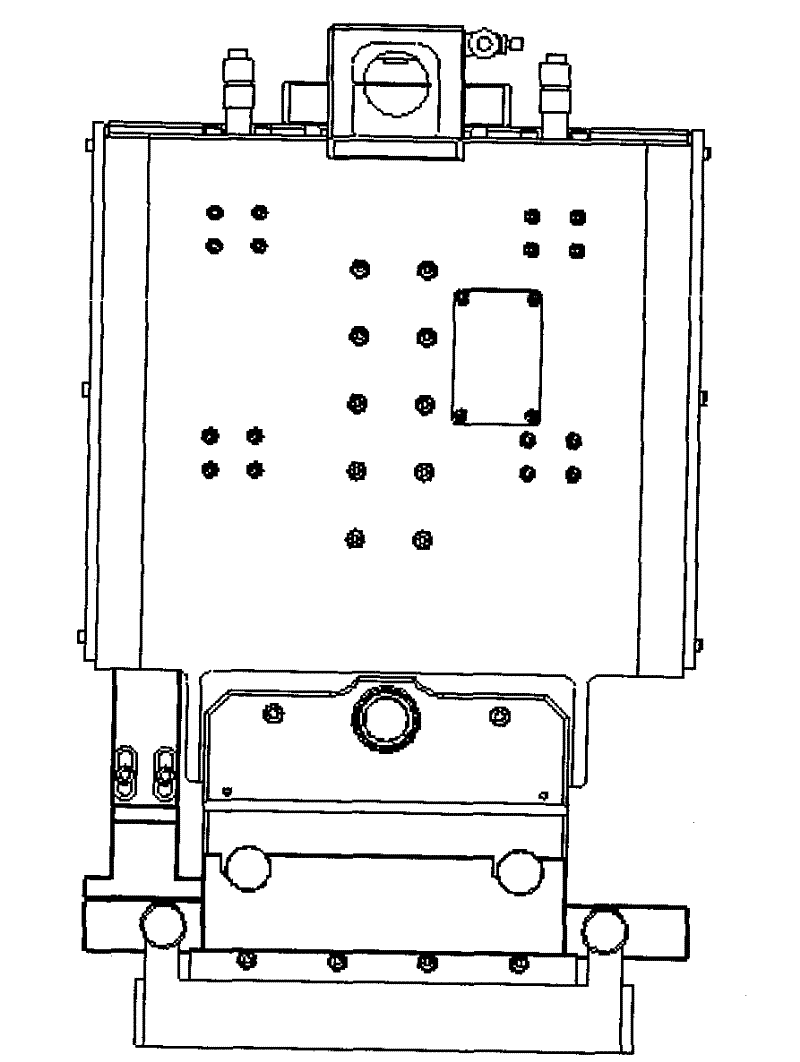

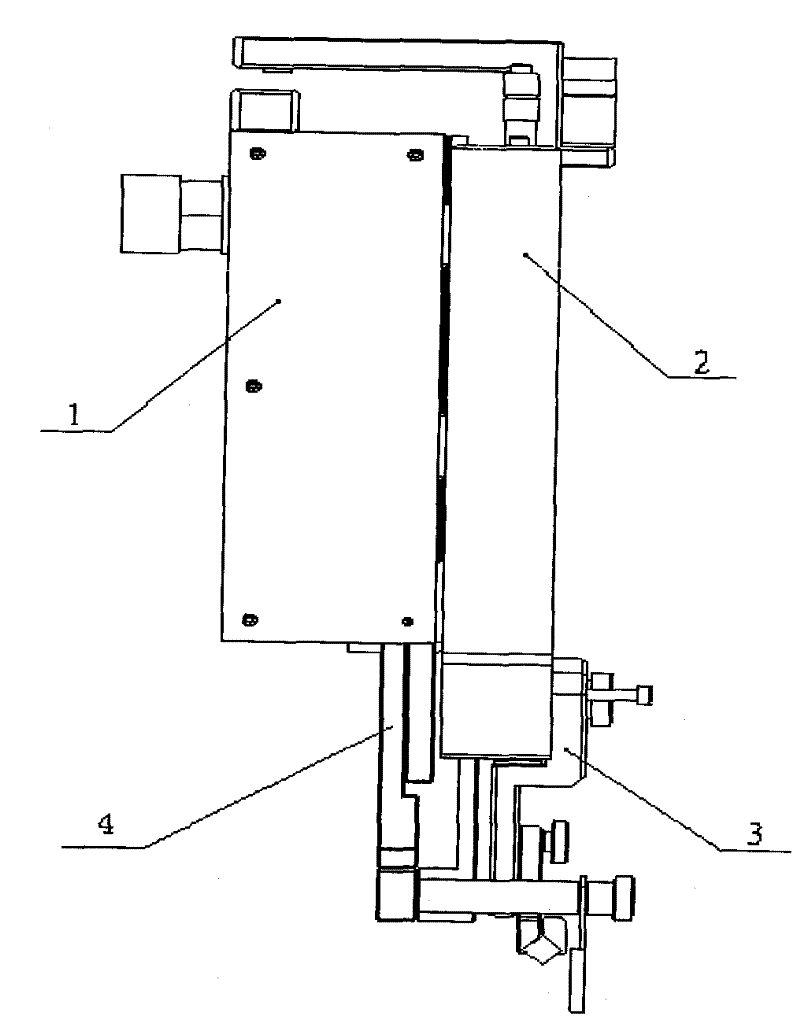

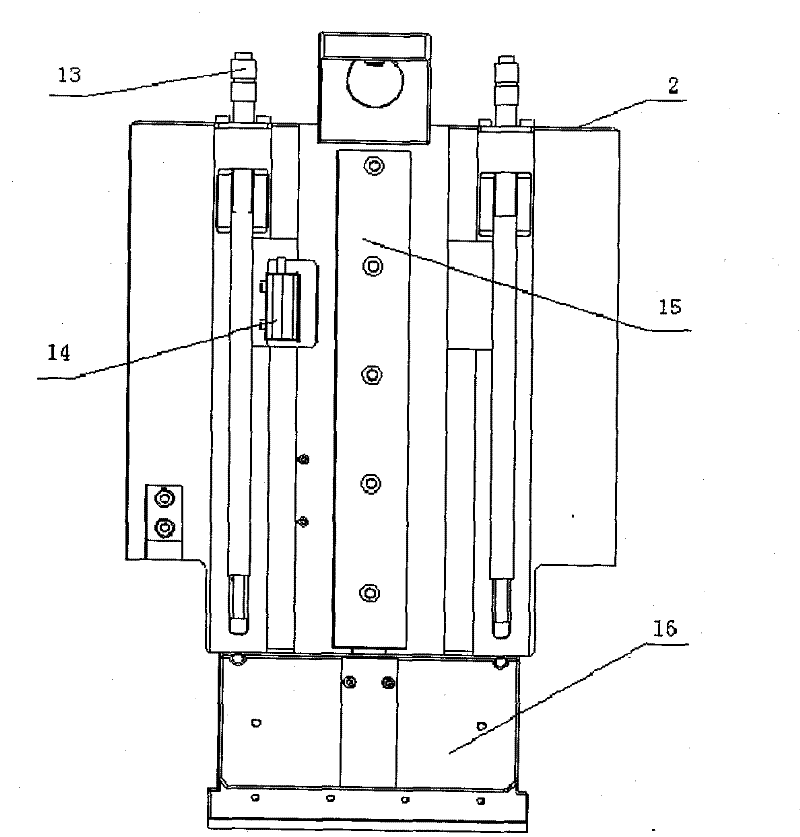

[0021] see Figure 1 to Figure 6 . The printing pressure control device of the cell printing machine includes an overall ink application seat 1 and an overall printing seat 2, the entire ink application seat 1 is connected to the ink application scraper body 4, and the overall ink application seat 1 is provided with a guide rail 6 and a linear motor stator 5; The overall printing seat 2 is connected to the printing scraper body 3, and the overall printing seat 2 is provided with a guide rail slider 8 and a pressure control linear motor mover 15; the weight balance mechanism of the overall printing seat 2 is provided: the overall printing seat 2 and The piston rod of the balance cylinder 9 is connected, and the balance cylinder 9 is connected with the air pressure regulating device; the balance cylinder 9 is installed parallel to the running direction of the motor, so as to balance the self-weight of the whole printing seat 2 and the friction force when the motor is running. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com