Ash column preparation device and method

A preparation device and ashing technology, applied in the field of carbonaceous material conversion, can solve problems such as high sealing requirements and unstable pressure, and achieve the effects of wide application range, convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

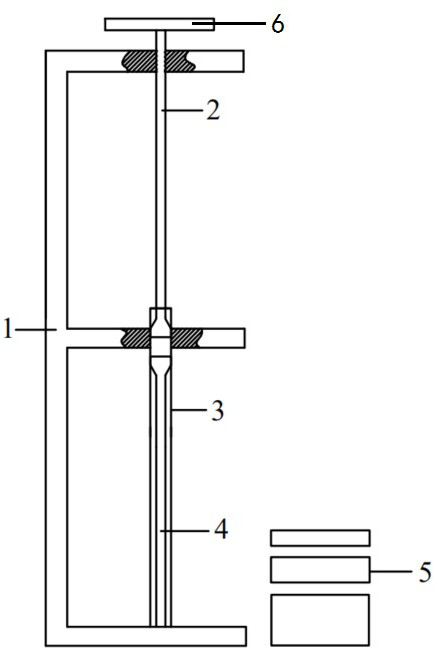

Image

Examples

Embodiment 1

[0032] Example 1: Preparation of 10MPa Wheat Straw Ash Column

[0033] Specific steps are as follows:

[0034] (1) Wheat straw samples were crushed to between 0.018-025mm, and made into ash at 575°C according to ASTM E1755-1 standard;

[0035] (2) Put about 1 gram of ash into the porcelain boat, add 0.08g / mL dextrin water suspension, mix well and make the coal ash reach the level that can be bonded by pressing with a knife;

[0036] (3) Put a round tube with an inner diameter of 5mm on the outside of the support rod, and add the wet ash into the round tube;

[0037] (4) Insert the stage and the pressure rod into the round tube filled with ash;

[0038] (5) According to the diameter of the round tube, the mass of the stage and pressure rod, and the pressure required for the ash column, the mass of the required weight is 5kg;

[0039] (6) Place a 5kg weight on the stage, and after 10 minutes of static pressure, remove the weight, stage and pressure bar;

[0040] (7) Slowly r...

Embodiment 2

[0042] Embodiment 2: the preparation of mixed ash column

[0043] Specific steps are as follows:

[0044] (1) Rice straw samples and coal ash were mixed at a ratio of 2:1, crushed to a size between 0.020-025mm, and made into ash at 575°C according to ASTM E1755-1 standard;

[0045] (2) Put about 1.5 grams of ash into the porcelain boat, add 0.1g / mL dextrin water suspension, mix well and make the coal ash reach the level that can be bonded by pressing with a knife;

[0046] (3) Put a round tube with an inner diameter of 8.0mm on the outside of the support rod, and add the wet ash into the round tube;

[0047] (4) Insert the stage and the pressure rod into the round tube filled with ash;

[0048] (5) According to the diameter of the circular tube, the mass of the stage and the pressure rod, and the pressure required for the ash column, the mass of the required weight is 7kg;

[0049] (6) Place a 7kg weight on the stage, and after 20 minutes of static pressure, remove the weig...

Embodiment 3

[0052] Embodiment 3: the preparation of mixed ash column

[0053] Specific steps are as follows:

[0054] (1) Corn straw samples, wheat straw samples and fly ash were mixed at a mass ratio of 1.5:1:1, crushed to a size between 0.020-025mm, and made into ash at 575°C according to the ASTM E1755-1 standard;

[0055] (2) Put about 2 grams of ash into the porcelain boat, add 0.15g / mL dextrin water suspension, mix well and make the coal ash reach the level that can be bonded by pressing with a knife;

[0056] (3) Put a round tube with an inner diameter of 10.0mm on the outside of the support rod, and add the wet ash into the round tube;

[0057] (4) Insert the stage and the pressure rod into the round tube filled with ash;

[0058] (5) According to the diameter of the round tube, the mass of the stage and the pressure rod, and the pressure required for the ash column, the mass of the required weight is 15kg;

[0059] (6) Place a 15lg weight on the stage, and after 5 minutes of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com