Pumping-assisting centering dropout prevention device of pumping rod

A sucker rod and centralizer technology, used in drill pipes, cleaning appliances, drilling equipment, etc., can solve the problems of single structure and function, can not fully meet the needs of oil production, and achieve reasonable structure, reduce leakage, and reduce recovery. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

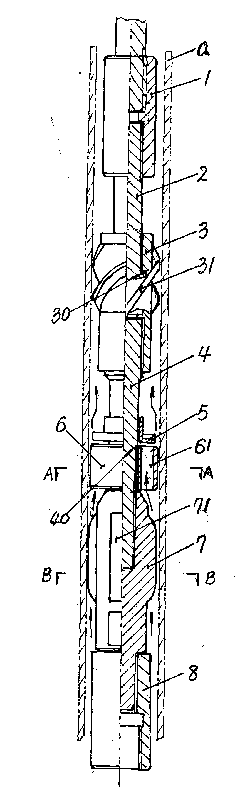

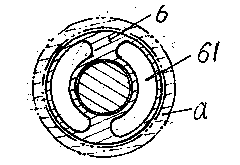

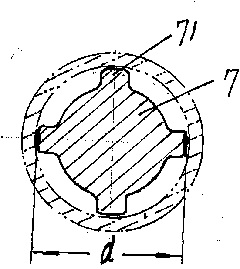

[0010] The present invention is made up of oiling rod joint 1, anti-loosening connecting rod 2, live joint 3, connecting rod 4, sealing cover 5, oil passage valve 6, centralizer 7 and lower oiling rod joint 8, the anti-loosing connecting rod 2 wears Installed in the inner hole of the joint 3, the upper end of the anti-off connecting rod 2 is connected with the internal thread interface of the oiling rod joint 1, and the lower end of the anti-off connecting rod 2 passes through the shaft shoulder and the stop provided in the inner hole of the joint 3. The mouth 30 is connected with sliding rotation; 3-4 helical teeth 31 are provided on the outer circle of the movable joint 3 to form a wax scraper; the upper end of the connecting rod 4 is connected with the internal thread interface at the lower end of the movable joint 3, and the sealing cover 5 is worn Installed on the connecting rod 4 and slidingly matched with the connecting rod 4, the oil passage valve 6 is mounted on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com