High accuracy oriented perforator

A technology for positioning and perforating, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of poor effect and inability to meet the needs of oil and gas field exploration and development, and achieve simple structure and prevent failure. Sand, the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

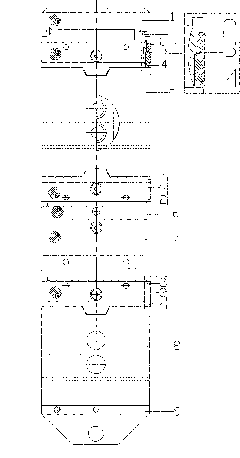

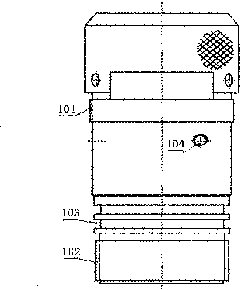

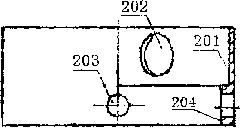

[0026] Such as Figure 1-9 As shown, the trapezoidal external thread 102 of the gun head 1 is connected to the upper end of the upper perforating gun body 5, the sealing ring groove 103 realizes sealing, the thread 101 is connected to the internal thread 204 of the adjusting ring 2, and the corrugated spring 3 is compressed to push the positioning locking ring 4. Lock the upper end of the upper perforating gun body 5 so that the fixing hole 202 and the positioning hole 402 are aligned with the threaded hole 104, and screw on the screw to fix it.

[0027] The trapezoidal thread 602 at the upper end of the middle upper joint 6 for positioning is connected to the lower end of the upper perforating gun body 5, the sealing ring groove 604 at the upper end of the middle upper joint 6 for positioning realizes sealing, and the thread 601 is connected to the internal thread 204 of the adjusting ring 2, and the compression corrugated spring 3 Push the positioning ring 4 to lock with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com