Magnetic levitation vehicle and method for lifting and/or lowering the vehicle

A magnetic levitation and locomotive technology, which is applied to motor vehicles, electric vehicles, railway vehicles, etc., can solve the problems of increasing the weight of locomotives and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

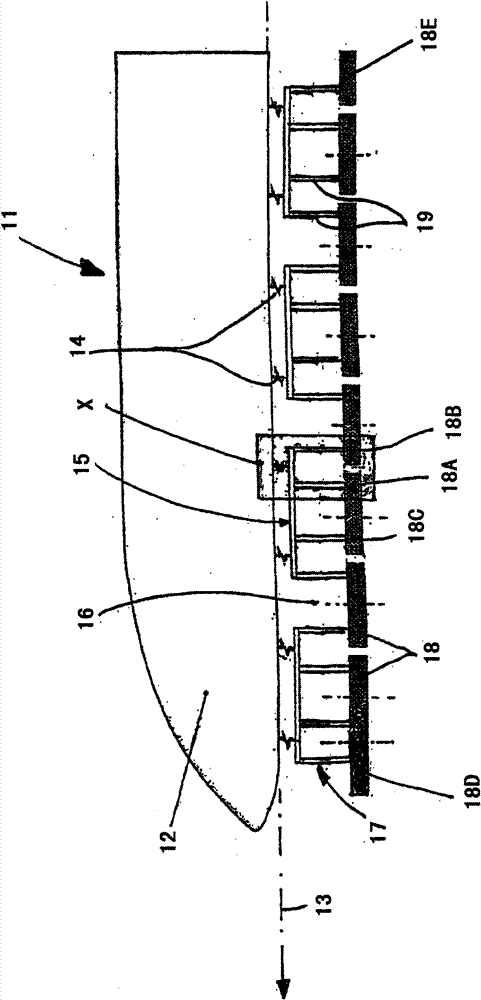

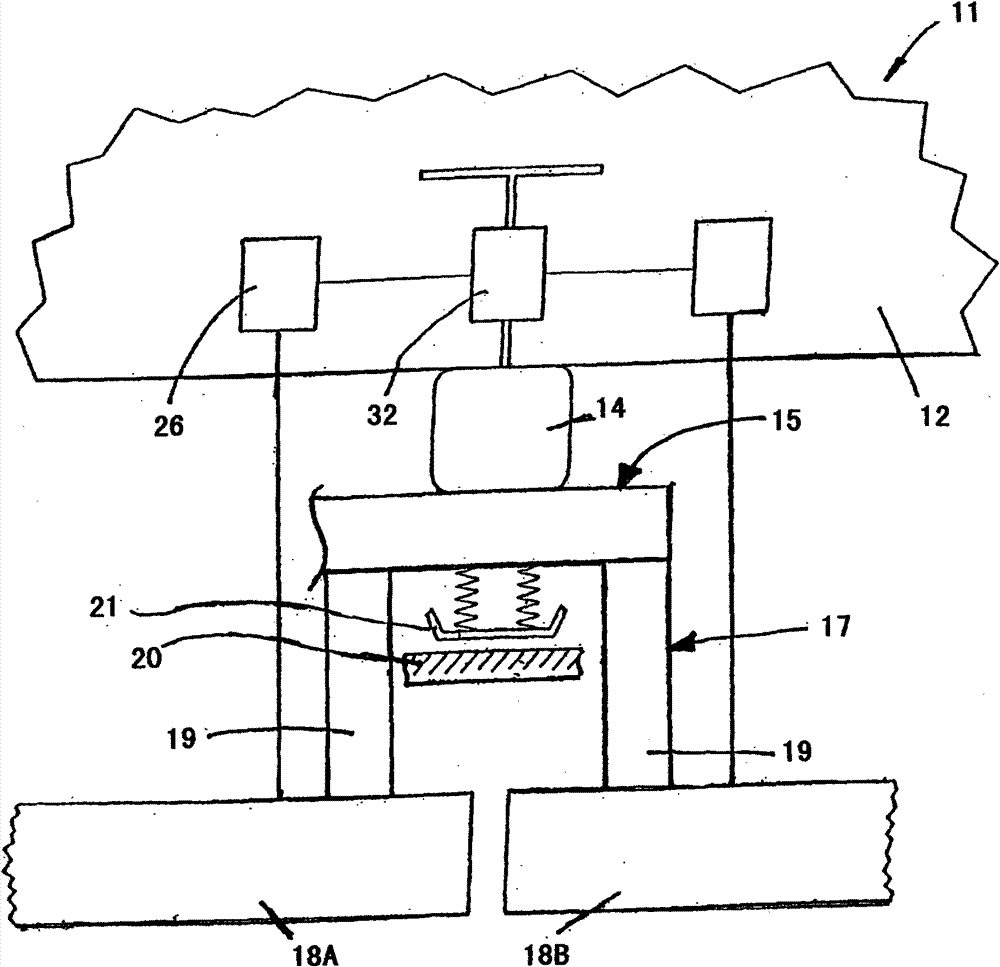

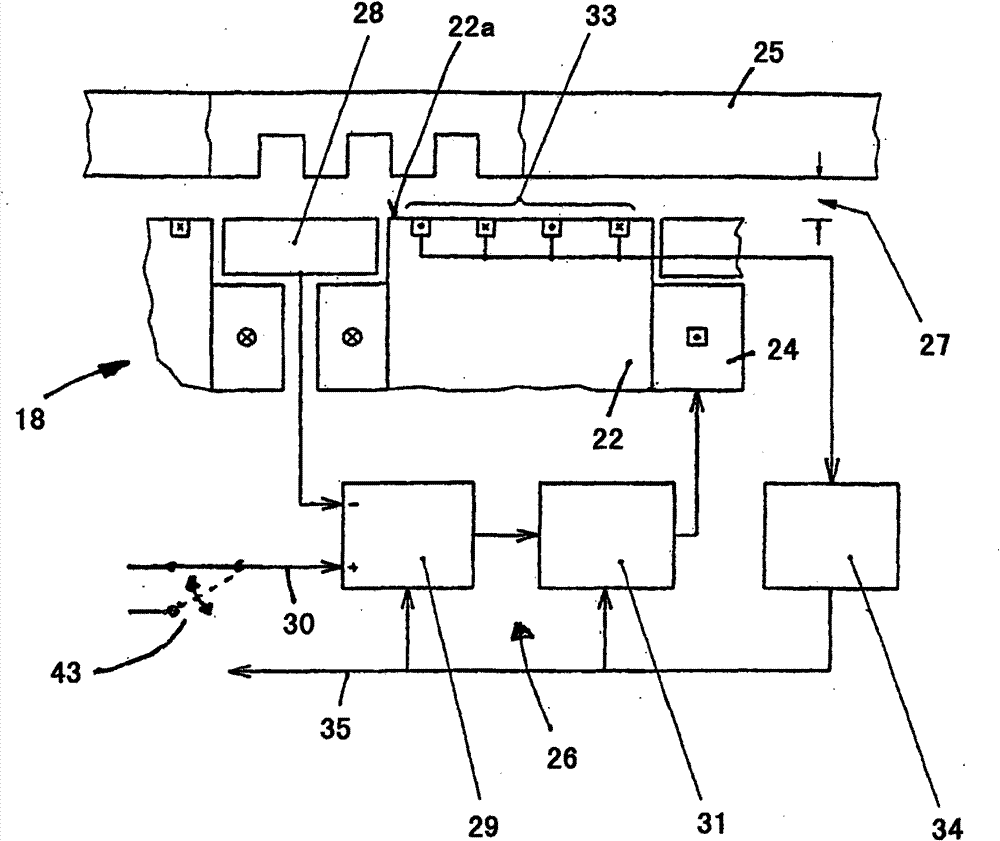

[0027] according to figure 1 A maglev locomotive 11 includes a compartment 12 on which a plurality of air springs 14 spaced along the longitudinal direction 13 of the maglev locomotive 11 are installed on its bottom surface, wherein the longitudinal direction 13 is also the traveling direction. Each air spring 14 acts on the front end or the rear end of each suspension bracket 15 configured, each suspension bracket supports the carriage 12 and is provided with a hinge point 16 formed as an intermediate space between them, and they are used to make each suspension bracket 15 The desired longitudinal and lateral movement can be achieved.

[0028] The suspension supports 15 are provided at their respective ends with suspension support frames 17 which are supported on support magnet units 18 . In this embodiment, each suspension support frame 17 has two support positions 19 arranged continuously along the longitudinal direction 13 (see also figure 2 ), which are fixed on the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com