Environmentally-friendly plate for raising rice seedlings and rice seedling production method

A rice seedling raising and production method technology, applied in application, cultivation, agriculture, etc., can solve the problems of increasing the intensity of rice farming operations, uneven seed sowing, and poor seedling uniformity, so as to reduce the use of medicines and pesticides for the prevention and treatment of blight Usage amount and pollution, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

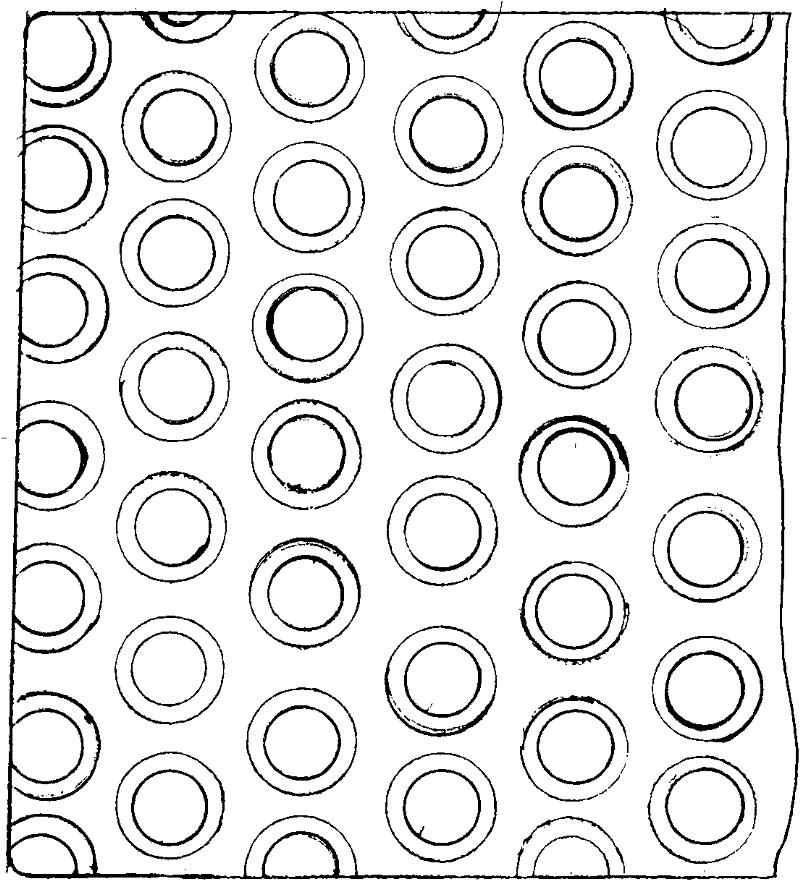

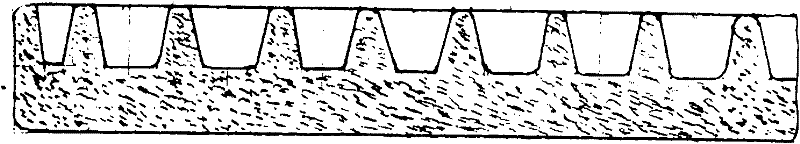

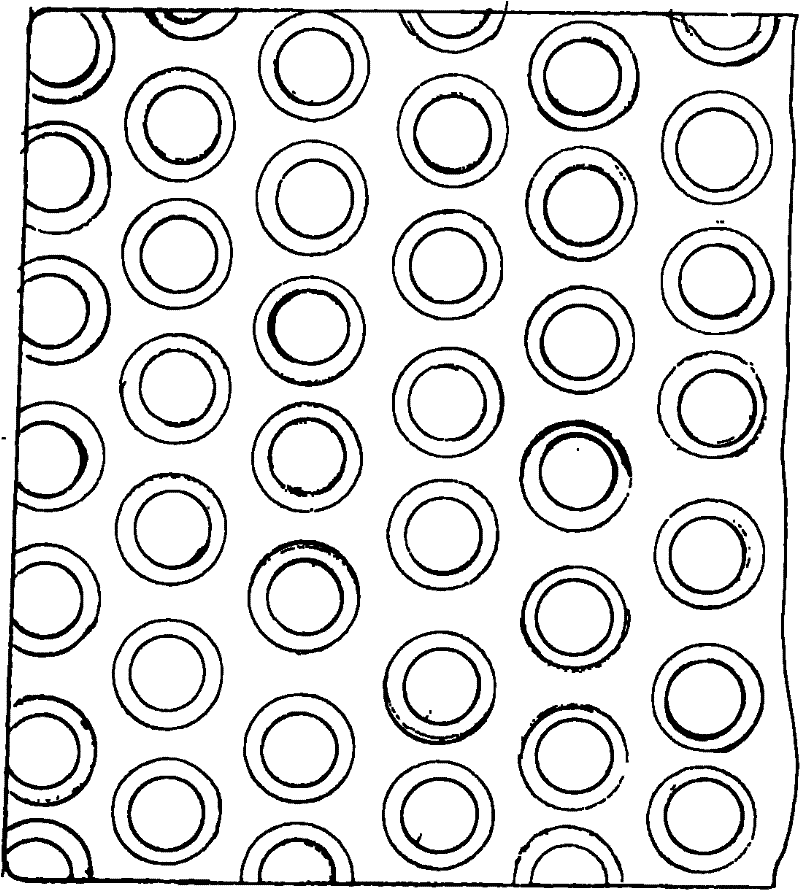

Image

Examples

experiment example

[0031] Experimental example: Experimental study on the seedling quality of rice seedling raising trays of the present invention

[0032] Several experiments have been carried out on rice seedling raising in environmentally friendly seedling trays, and compared with the conventional nutrient soil tray seedling raising method in production. The test area is 90 square meters, and the transplanting area is 18.7 mu. The quality of the seedlings raised in the environment-friendly seedling tray is better, which is consistent with or slightly better than that of the seedlings raised in the conventional nutrient soil tray.

[0033] The advantages of the environmentally friendly seedling trays are that the temperature can be increased quickly, and the seedlings can be raised and transplanted early; no weeding and sealing chemicals are required. In order to verify the comparison of seedling quality with conventional nutrient soil trays, this test was carried out. The test methods and res...

Embodiment 1

[0052] Formula, comprises the raw material of following weight percent:

[0053] Crushed corn stalks 40 mesh, 60%;

[0054] Industrial processing pulp waste liquid, 25%;

[0055] Industrial boiling slag powder 40 mesh, 15%.

[0056] method:

[0057] (1) Material preparation: prepare 40 meshes of corn stalks, industrial processing pulp waste residue liquid, and industrial boiling furnace slag powder, and prepare them in proportion;

[0058] (2) Raw material crushing: crush the corn stalks into 40 meshes with a common grinder, then stack them and wait for fermentation;

[0059] (3) Fermentation: Add Candida yeast per 1000 kg of crushed corn stalks, containing 4×10 8 -10×10 8 CFU / g, plant lactic acid bacteria, containing 10×10 8 -30×10 8 CFU / g, the ratio of Candida and plant lactic acid bacteria is 35%: 65% mixed solution, the addition amount is 0.5 kg, and the dilution of the bacterial solution should be based on the humidity of the stalk, so it needs to be evenly sprinkl...

Embodiment 2

[0067] Comprising the following raw materials in weight percentage:

[0068] Crushed corn stalks 50 mesh, 70%;

[0069] Industrial processing pulp waste liquid 20%;

[0070] Industrial boiling slag powder 50 mesh, 10%.

[0071] method:

[0072] (1) Raw material preparation: prepare 50 meshes of corn stalks, industrial processing pulp waste residue liquid, and industrial boiling furnace slag powder, and prepare them in proportion;

[0073] (2) Raw material crushing: crush the corn stalks into 50 meshes with a common grinder, then stack them and wait for fermentation;

[0074] (3) Fermentation: Add Candida yeast per 1000 kg of crushed corn stalks, containing 4×10 8 -10×10 8 CFU / g, plant lactic acid bacteria, containing 10×10 8 -30×10 8 CFU / g, the ratio of yeast and lactic acid bacteria is 35%: 65% mixed solution, the amount added is 0.5 kg, the dilution of the bacterial solution should be based on the humidity of the straw, and the straw needs to be evenly sprinkled with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com